4.) Unthread valve cap and remove wiper seal and duck bill valve to clean. Rinse all remaining parts and drain all fluid from the RAPIDROLLERTM .

5.) Remove tubing from frame (if needed) by pinching hose clamps. Flush frame and tubing. Replace tubing and secure with hose clamps.

6.) Always purchase a perforated roller cover. A standard roller will not work.

S | S1 |

APID OLLERTM

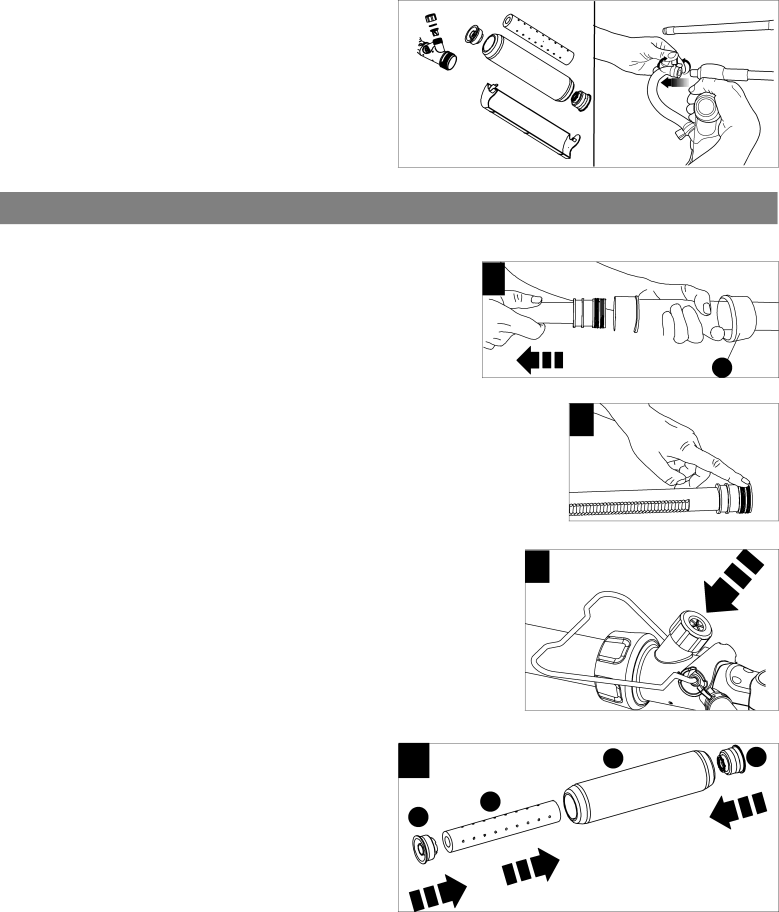

Lubrication helps with normal operation and should be done after cleaning and before each use. 1.) Turn the threaded assembly collar (a) near the trigger counterclockwise until the main

tube assembly slides off.

NOTE: When reassembling, black threaded collar (a) should be towards trigger handle.

![]()

![]()

![]()

![]() a

a

2.) Apply petroleum jelly around and in between the rubber seals shown. Reassemble making sure the rubber seals are not twisted or damaged. Tighten the locking collar.

3.) Apply petroleum jelly to the duck bill valve and wiper seal and replace within unit threading the valve cap back into place.

4.) Apply petroleum jelly to the inner seals on the end caps (c & d) then assemble the roller by placing the core (a) inside of roller cover (b) and attaching end caps and as shown.

d | a |

6