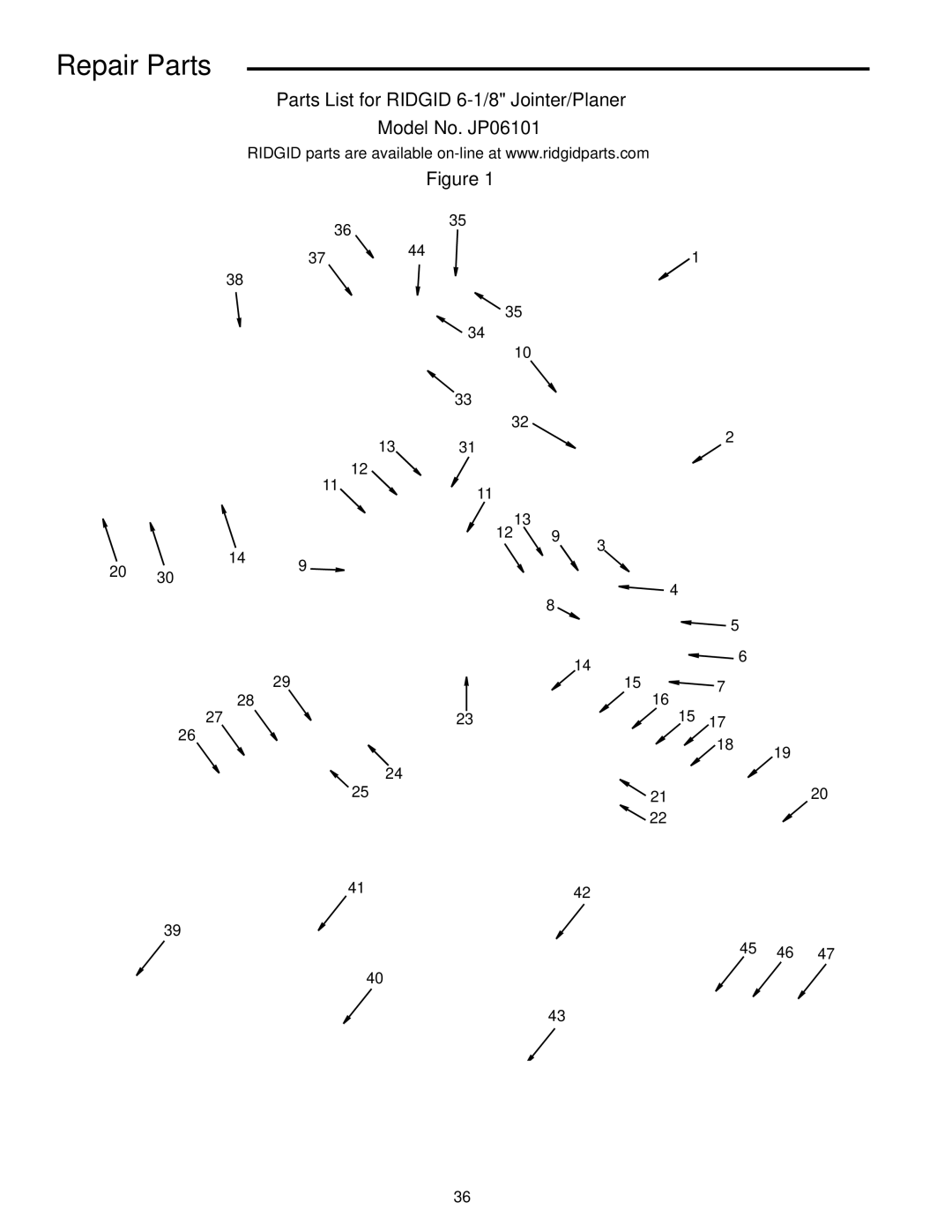

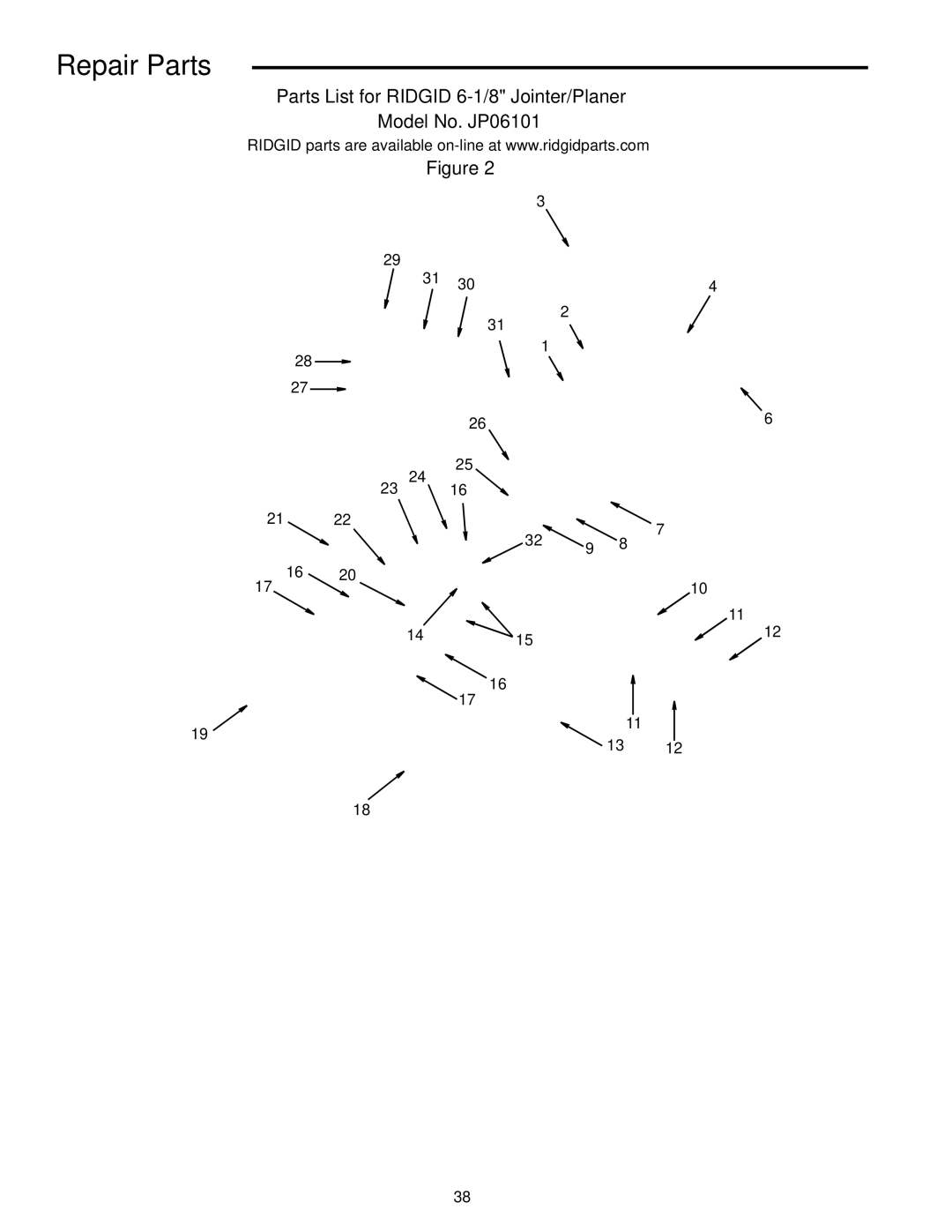

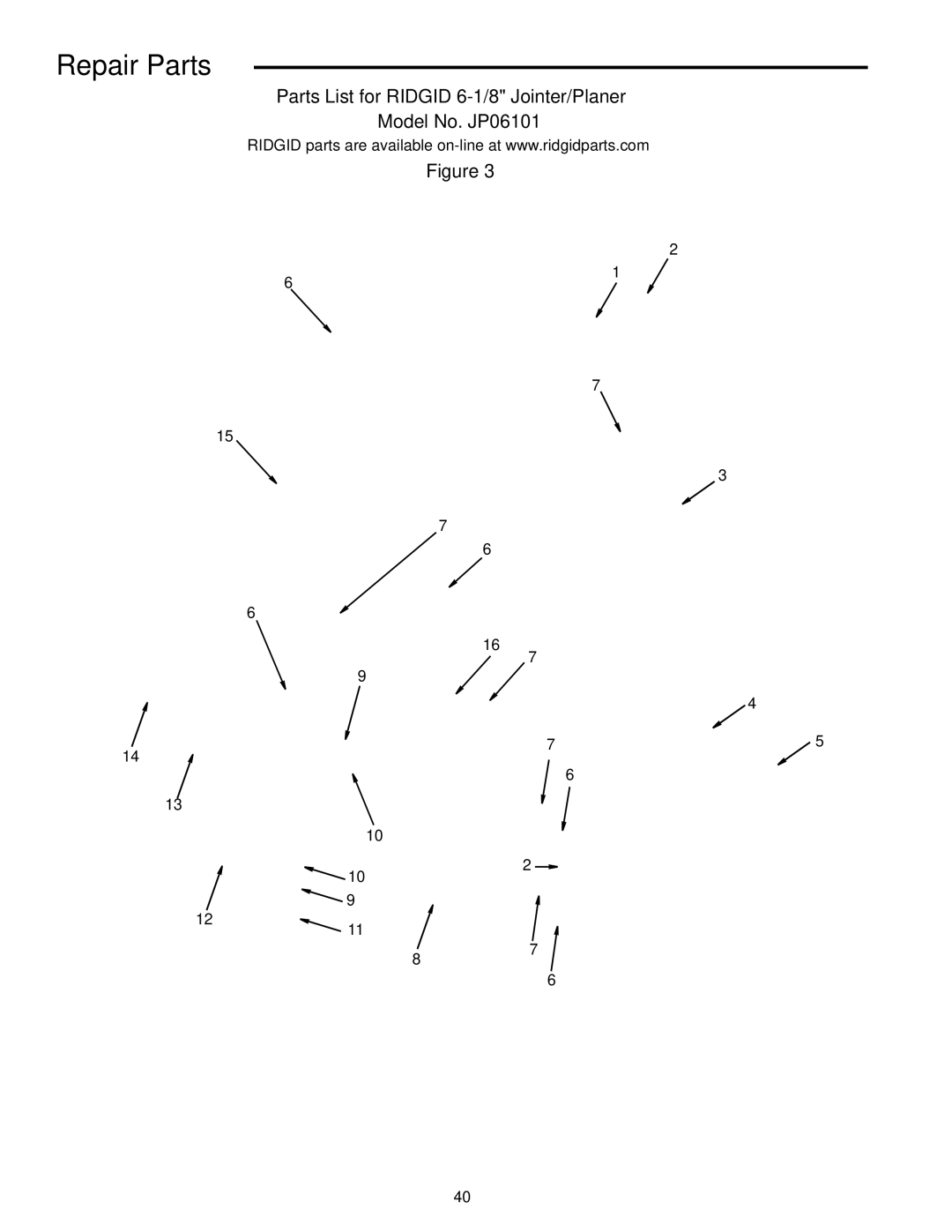

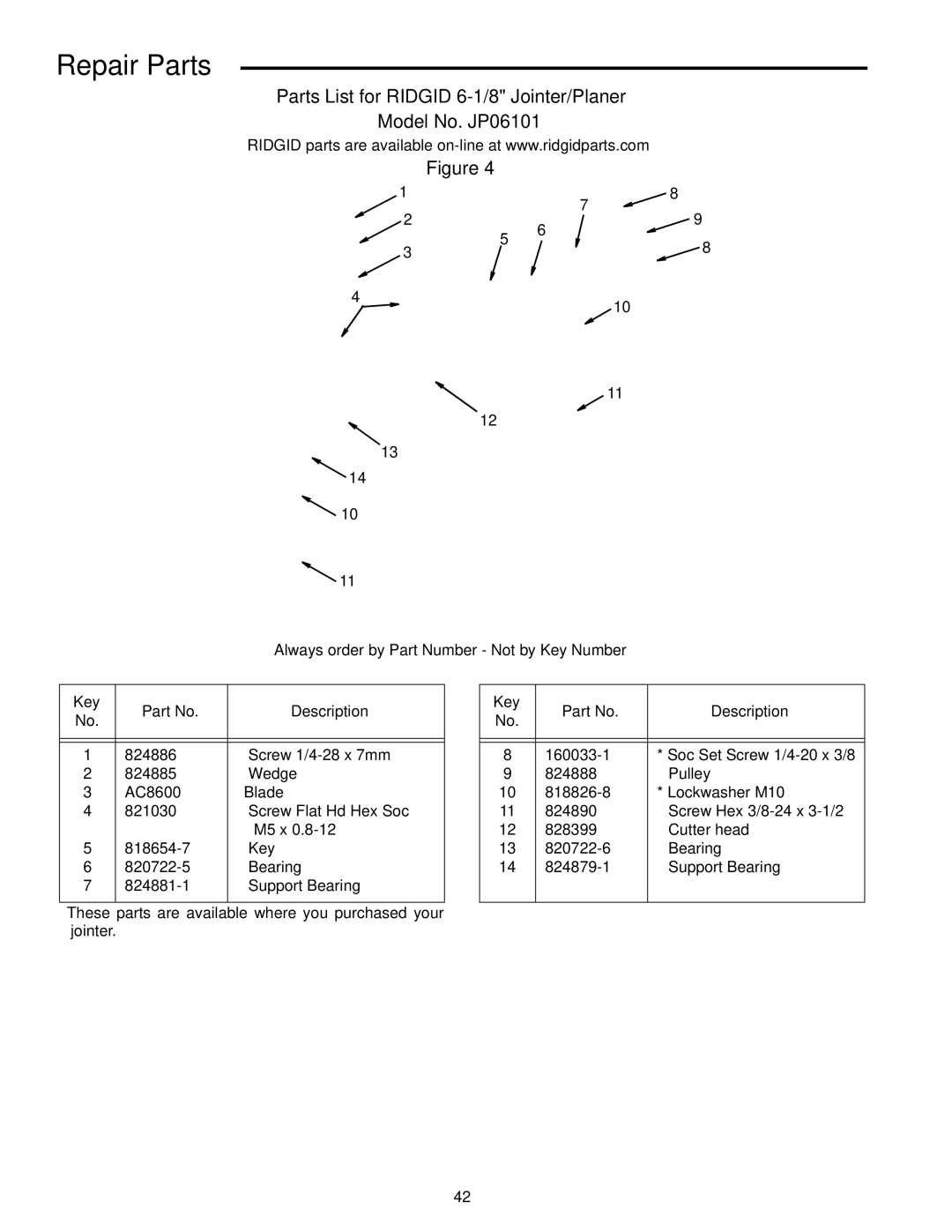

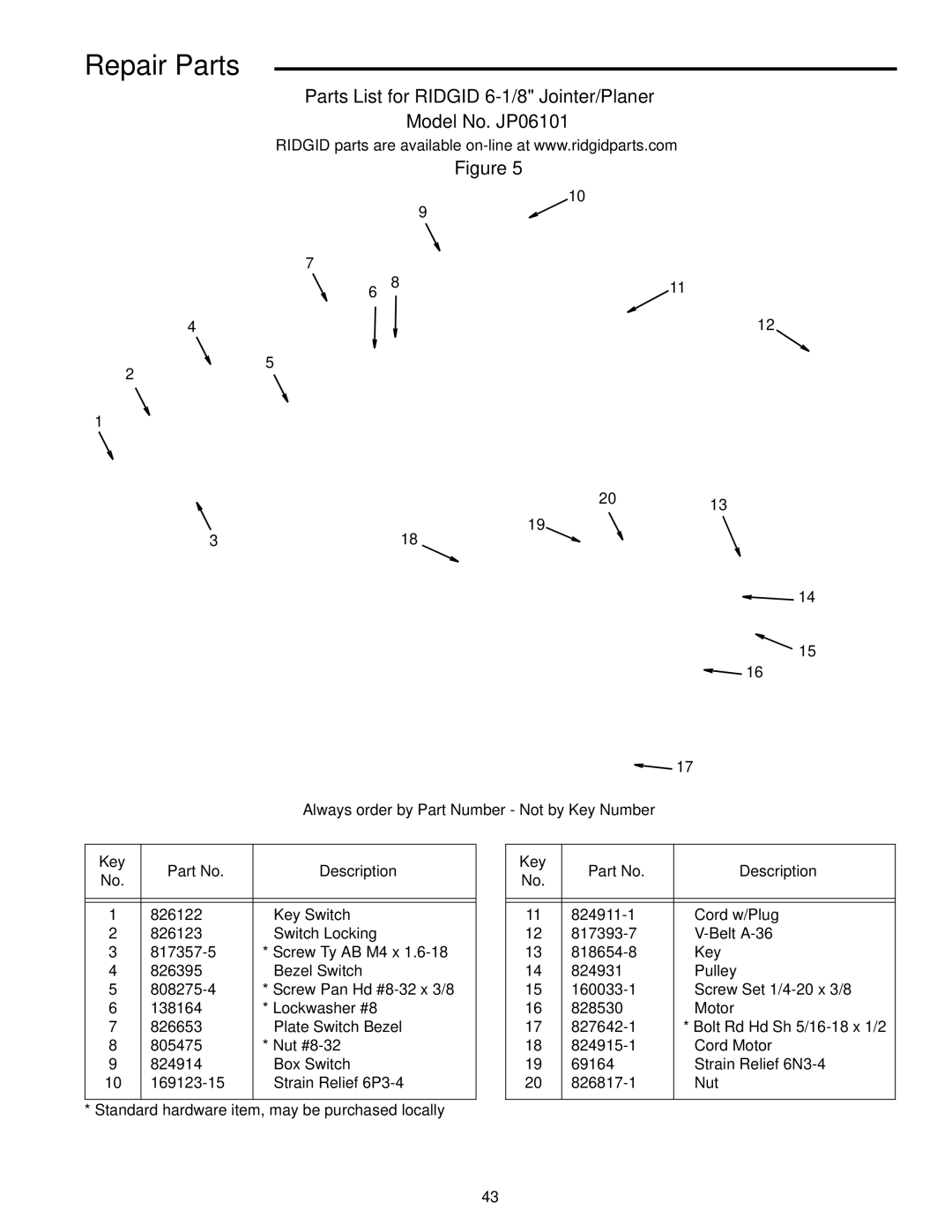

Repair Parts

Parts List for RIDGID

Model No. JP06101

RIDGID parts are available

Figure 1

Always order by Part Number - Not by Key Number

Key | Part No. | Description | |

No. | |||

|

| ||

|

|

| |

|

|

| |

1 | 826655 | Guard Cutter | |

2 | Table Infeed | ||

3 | 828397 | Pointer Indicator | |

4 | 822495 | * Screw Pan Hd. | |

5 | 824867 | Knob | |

6 | 824866 | Retainer Knob | |

7 | * Screw Pan Hd 8/32 x 5/8 | ||

8 | 824868 | Spring | |

9 | 824865 | Retainer | |

10 | * Screw Pan Hd M5 x | ||

11 | 824856 | Gib | |

12 | * Screw Set | ||

13 | 805478 | * Nut Hex | |

14 | 824859 | Screw Elevation | |

15 | 824860 | Washer Brass | |

16 | 824858 | Clamp | |

17 | * Screw Set | ||

18 | 824861 | Collar | |

19 | 826524 | Handwheel | |

20 | 828711 | Screw Pan Hd | |

21 | * Lockwasher 8mm | ||

22 | * Screw Cap | ||

23 | Base | ||

24 | 828649 | Block Asm Depth | |

|

|

|

* Standard hardware item, may be purchased locally

†These replacement parts are available where you pur- chased your jointer.

Key | Part No. | Description | |

No. | |||

|

| ||

|

|

| |

|

|

| |

25 | 9421622 | Screw Cap | |

26 | 826529 | Knob Plunger | |

27 | 824873 | Housing Plunger | |

28 | 824872 | Spring | |

29 | 824874 | Plunger | |

30 | 826523 | Knob Outfeed | |

31 | 824857 | Screw Wing | |

32 | Pin Spring 5 x 30 | ||

33 | 828531 | Slide Fence | |

34 | 824863 | Washer 3/8 x 20mm x 3mm |

35

36

37 | 828523 | Key |

38 | Table Outfeed | |

39 | AC8601 | † Push Block |

40 | 828402 | Angle Gauge - Part A |

41 | 828403 | Angle Gauge - Part B |

42 | * Wrench Hex “L” M3 | |

43 | 821202 | * Wrench Box M8/M10 |

44 | Washer Flat 10mm | |

45 | SP6442 | Operator’s Manual English |

46 | SP6442S | Operator’s Manual Spanish |

47 | SP6442F | Operator’s Manual - French |

37