Motor Specifications and Electrical Requirements (continued)

General Electrical Connections

DANGER: To reduce the risk of electrocution:

1.Use only identical replacement parts when servic- ing. Servicing should be performed by a qualified service technician.

2.Do not use in rain or where floor is wet.

This tool is intended for indoor residential use only.

![]() WARNING: Do not permit fingers to touch the ter- minals of plug when installing or removing the plug to or from the outlet.

WARNING: Do not permit fingers to touch the ter- minals of plug when installing or removing the plug to or from the outlet.

If power cord is worn or cut, or damaged in any way, have it replaced immediately.

110-120 Volt, 60 Hz. Tool Information

The plug supplied on your tool may not fit into the outlet you are planning to use. Your local electrical code may require slightly different power cord plug connections. If these differences exist refer to and make the proper adjustments per your local code before your tool is plugged in and turned on.

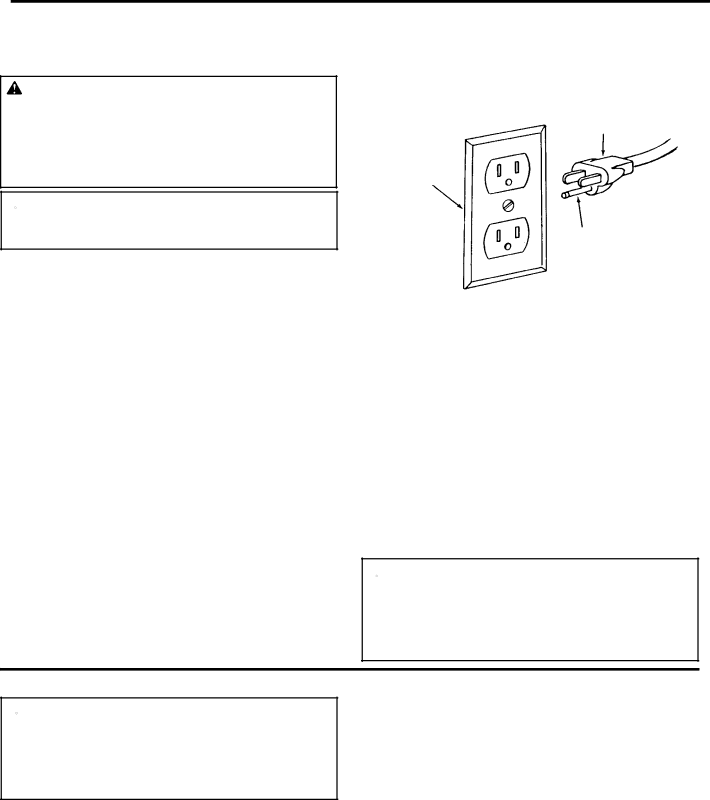

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment grounding con- ductor and a grounding plug, as shown. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes

and ordinances.

3-Prong Plug

Properly

Grounded

Outlet

Grounding

Prong

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified electrician. Improper connection of the equipment grounding con- ductor can result in a risk of electric shock. The conduc- tor with insulation having an outer surface that is green with or without yellow stripes is the equipment grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the

If the grounding instructions are not completely under- stood, or if you are in doubt as to whether the tool is prop- erly grounded check with a qualified electrician or service personnel.

![]() WARNING: If not properly grounded, this tool can cause an electrical shock, particularly when used in damp locations, in proximity to plumbing, or out of doors. If an electrical shock occurs there is the poten- tial of a secondary hazard, such as your hands con- tacting the knives.

WARNING: If not properly grounded, this tool can cause an electrical shock, particularly when used in damp locations, in proximity to plumbing, or out of doors. If an electrical shock occurs there is the poten- tial of a secondary hazard, such as your hands con- tacting the knives.

Changing Motor Voltage

![]() WARNING: If not properly grounded, this tool can cause an electrical shock, particularly when used in damp locations, in proximity to plumbing, or out of doors. If an electrical shock occurs there is the poten- tial of a secondary hazard, such as your hands con- tacting the knives.

WARNING: If not properly grounded, this tool can cause an electrical shock, particularly when used in damp locations, in proximity to plumbing, or out of doors. If an electrical shock occurs there is the poten- tial of a secondary hazard, such as your hands con- tacting the knives.

NOTE: The jointer is prewired at the factory for 120V operation. Use the following procedure to change motor voltage. To change to 240V application an additional wire nut is supplied from the factory. This part is included in the loose parts.

1.Unplug the jointer/planer before making or changing any connections. Open the motor junction box cover located on the side of the motor.

2.Remove and discard the electrical tape from the wire nuts. Remove wire nuts.

3.Reconnect the leads as shown in the “Wiring Diagram” section at the rear of manual.

4.Reinstall the wire nuts and wrap with two layers of new U.L. listed electrical tape per wire nut.

5.Recheck your wiring to the wiring diagrams. Do this so you can be sure that the wiring is correct.

6.Reinstall the junction box cover.

7.Cut off the 120 volt power cord plug and replace it with a (3 blade) 240 volt 15 amp U.L. listed plug. (See illus- tration of 240V plug & receptacle.) Connect the power cord white and black leads, respectively, to the “hot” plug blade terminals and connect the power cord green grounding wire to the plug ground prong termi- nal.

8.Plug your jointer into a

8