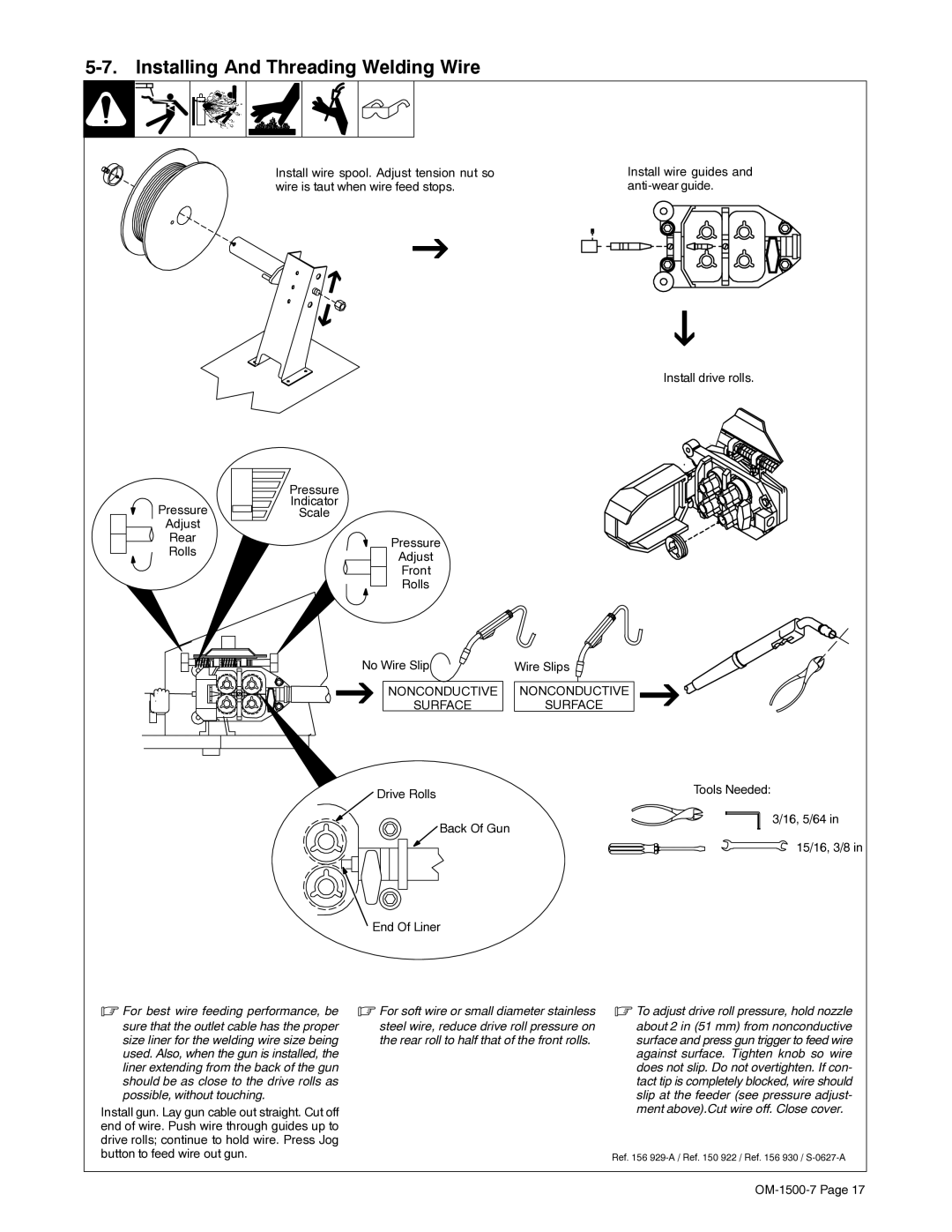

5-7. Installing And Threading Welding Wire

Install wire spool. Adjust tension nut so | Install wire guides and | ||||

wire is taut when wire feed stops. | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

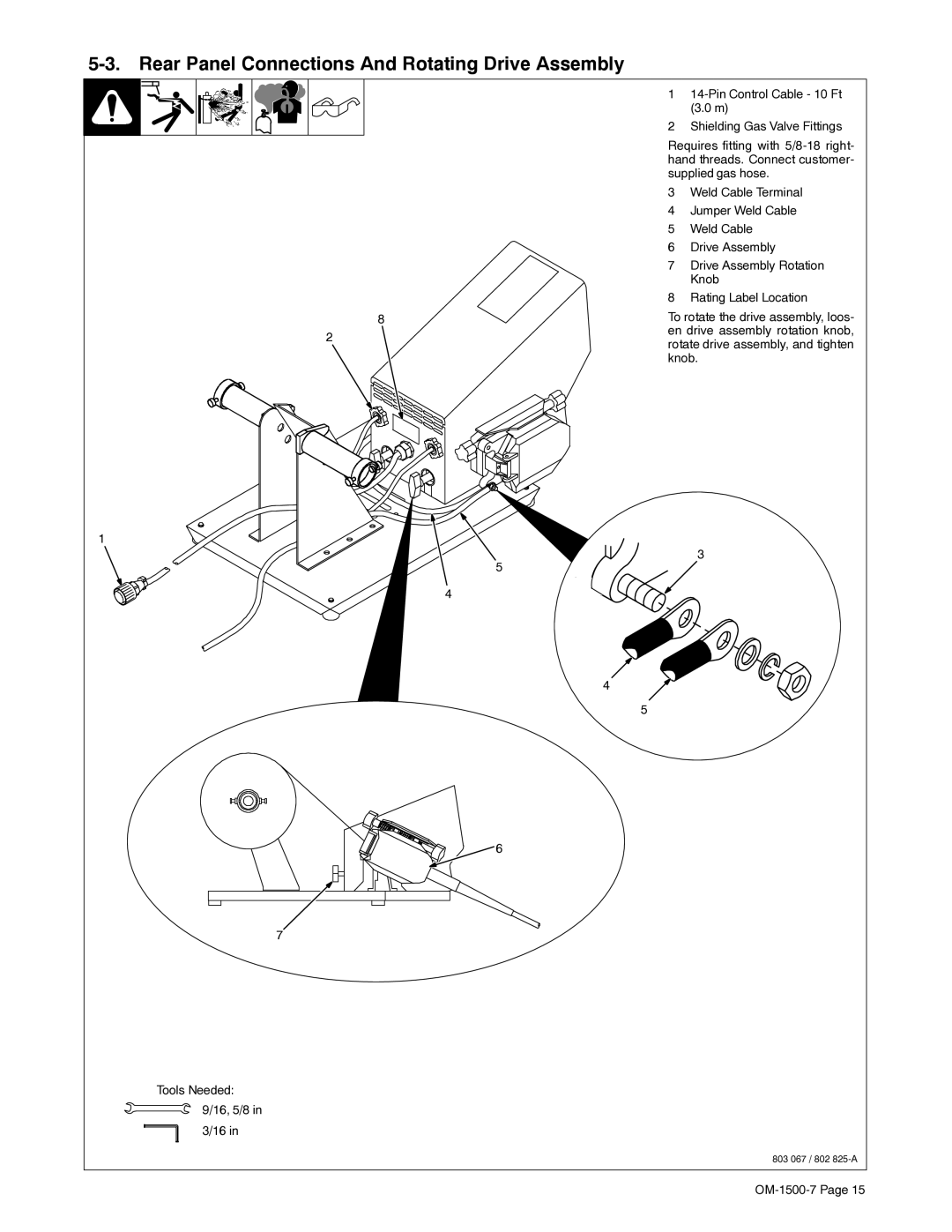

Install drive rolls.

| Pressure | |

Pressure | Indicator | |

Scale | ||

Adjust |

| |

Rear | Pressure | |

Rolls | ||

Adjust | ||

| ||

| Front | |

| Rolls |

No Wire Slip | Wire Slips |

NONCONDUCTIVE | NONCONDUCTIVE |

SURFACE | SURFACE |

Drive Rolls |

| Tools Needed: |

|

| |

| Back Of Gun | 3/16, 5/64 in |

|

| |

|

| 15/16, 3/8 in |

End Of Liner

. For best wire feeding performance, be | . For soft wire or small diameter stainless | . To adjust drive roll pressure, hold nozzle |

sure that the outlet cable has the proper | steel wire, reduce drive roll pressure on | about 2 in (51 mm) from nonconductive |

size liner for the welding wire size being | the rear roll to half that of the front rolls. | surface and press gun trigger to feed wire |

used. Also, when the gun is installed, the |

| against surface. Tighten knob so wire |

liner extending from the back of the gun |

| does not slip. Do not overtighten. If con- |

should be as close to the drive rolls as |

| tact tip is completely blocked, wire should |

possible, without touching. |

| slip at the feeder (see pressure adjust- |

Install gun. Lay gun cable out straight. Cut off |

| ment above).Cut wire off. Close cover. |

end of wire. Push wire through guides up to |

|

|

drive rolls; continue to hold wire. Press Jog |

|

|

button to feed wire out gun. |

| Ref. 156 |