6-12 Auxiliary Menus (Continued)

Reset To Factory Settings

A reset menu is displayed if the following four push buttons are pressed simultaneously: Program, Sequence, upper display, and Set- up. The upper display indicates “WIPE” . The lower display indicates “OFF”. The lower push button is active indicating that the Adjust control can be used to change the unit to “WIPE ON”. When “WIPE ON” is set, if the ori- ginal four push buttons are simultaneously pressed a second time, the unit will reset all settings to factory default except the arc time and arc cycle counts. If a reset is not desired, set the display to “WIPE OFF” and simulta- neously press the Program, Sequence, upper display, and Setup push buttons to exit the re- set menu.

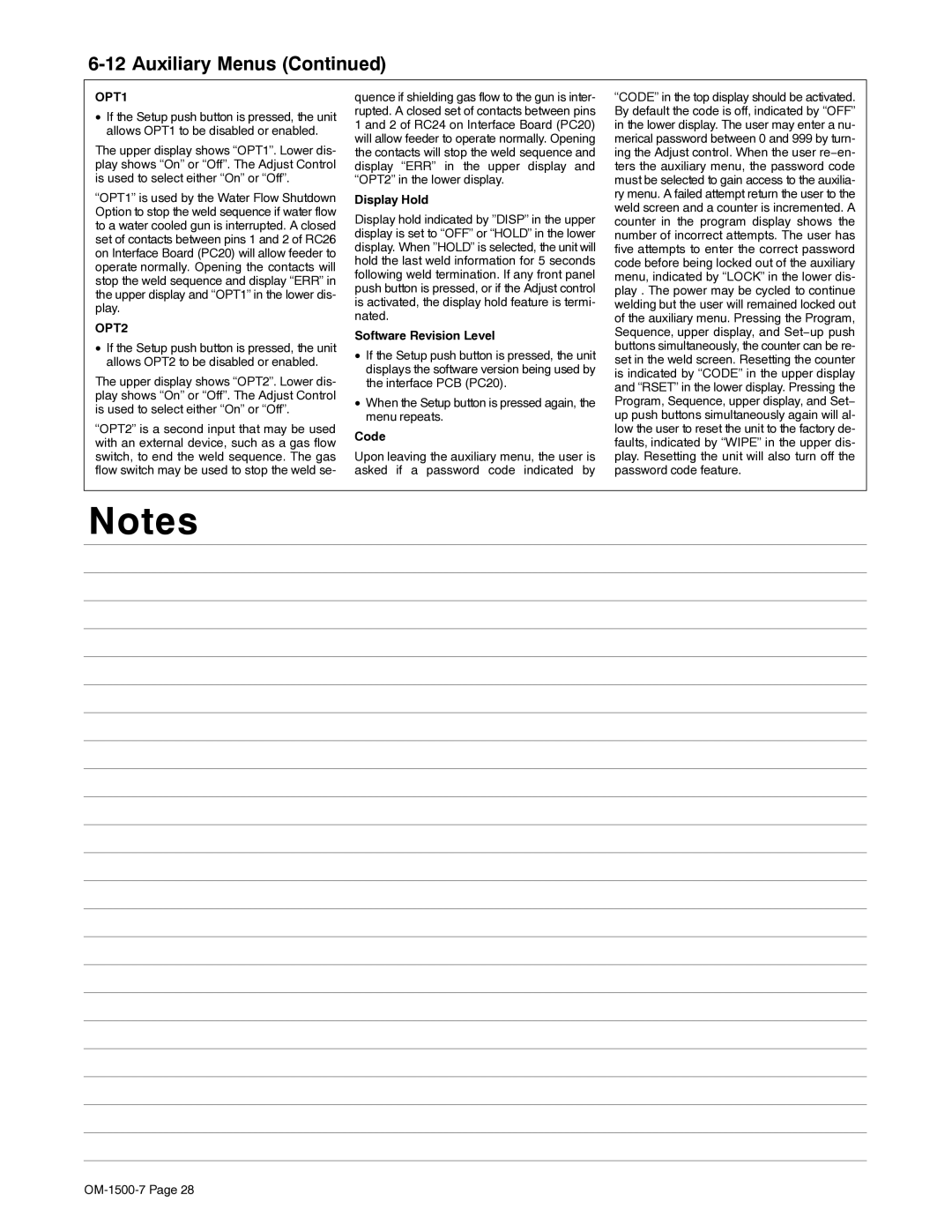

Auxiliary Menu

•An auxiliary menu is provided if both the Se- quence and Setup push buttons are pressed simultaneously. The Setup push button and sequence push button LEDS flash when the auxiliary menu is displayed.

Pushing the Setup push button will step through the menu. Pushing the sequence push button will step through the menu in re- verse.

.The auxiliary menu may be exited at any

time by pressing both the Sequence push button and the Setup push buttons simul- taneously.

V-Min And V-Max

•If the Setup push button is pressed, the unit allows the setting of the manual override power source min and max voltage preset range. The minimum voltage is displayed in the upper display and the lower display indi- cates “VMIN”. When the Setup push button is pressed the unit displays the maximum voltage setting of the welding power source. The maximum voltage is displayed in the upper display and the lower display indicates “VMAX”.

In both cases, the Adjust control is used to specify the minimum and maximum voltage settings of the welding power source. The settings correspond to arc voltage obtained at minimum command and arc voltage obtained at maximum command.

This method of setting “VMIN” and “VMAX” may be used if the power source being used is not listed in the Power Source Selection Menu.

.If a default power source has already

been selected with the Power Source Selection menu, setting “VMIN” and “VMAX” will override the default power source settings.

.The power source selection menu must

be set to “OFF” when overriding the de- fault “VMIN” or “VMAX” settings.

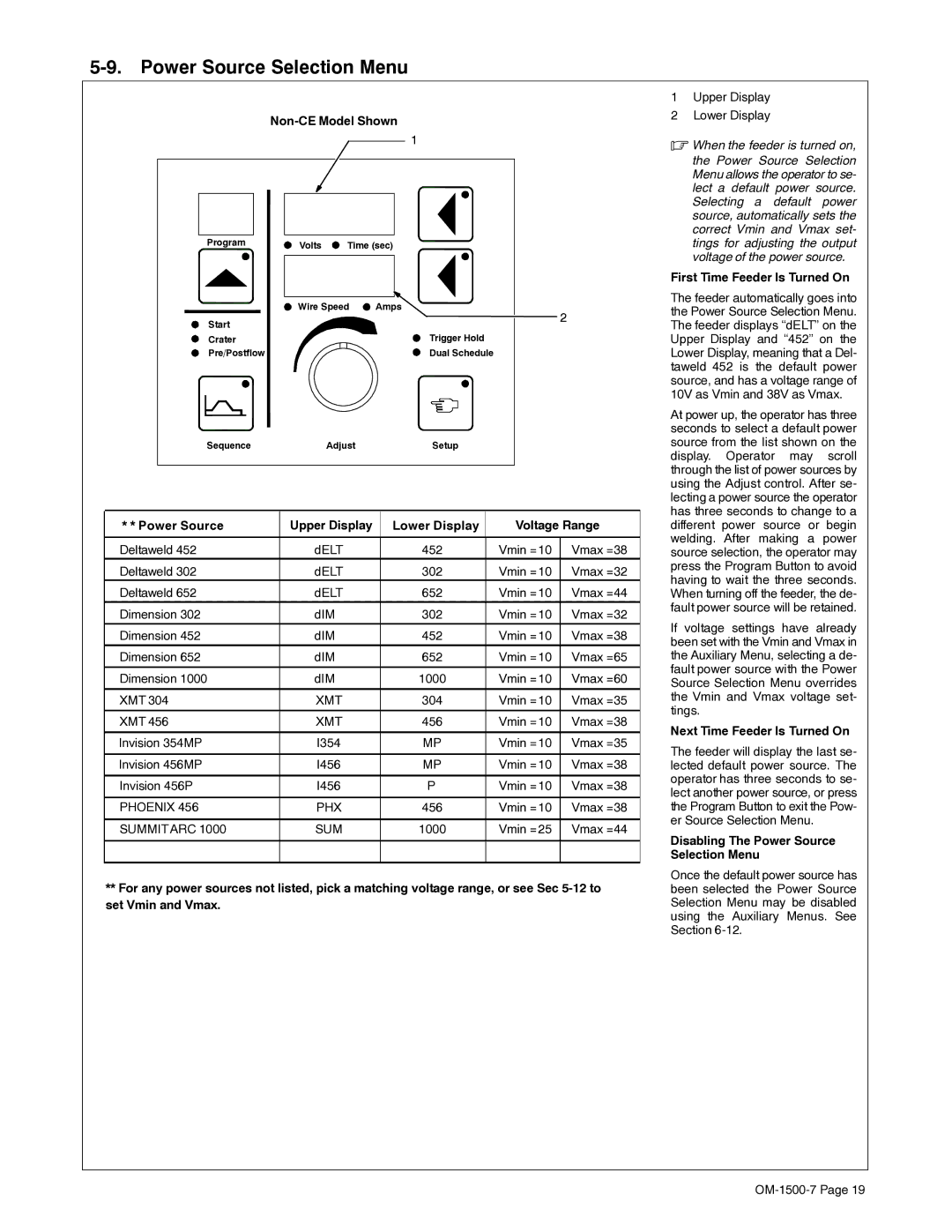

Power Source Selection Menu

•If the Setup push button is pressed, the unit allows the Power Source Selection menu to be disabled or enabled.

The upper display shows “PSS”. Lower dis- play shows “On” or “Off”. The Adjust Control

is used to select either “On” or “Off”.

Arc Time

•If the Setup push button is pressed, the unit displays arc time in hours.

Arc time is indicated by the Program display showing “HR”. Arc time is shown in the lower display.

Cycles

•If the Setup push button is pressed, the unit displays the number of cycles.

Arc cycles are indicated by the Program dis- play showing “CL”. The arc cycle count is shown in the lower display.

Run-In

•If the Setup button is pressed, the unit al- lows setting the

The upper display indicates “RUNI”. The lower display indicates “AUTO”, meaning the factory set automatic

Pressing the lower display button allows a manual setting the

Pressing the lower display button allows disabling of the

Burnback

•If the Setup push button is pressed, the unit allows burnback time to be set.

Burnback time and voltage can be specified when the lower display indicates “BURN” and the upper display indicates the burnback time or voltage. The Adjust control is used to set the desired burnback time or voltage. Burn- back settings, like

Trigger Hold Setup

•If the Setup push button is pressed, the unit allows trigger hold delay time to be set.

Trigger hold delay time is indicated by ”HOLD” in the lower display and the hold delay time in the upper display. The adjust control can be used to specify a new delay time for trigger hold. Trigger hold delay time is the minimum amount of time the trigger must be held for trigger hold to work when the trig- ger is released (the trigger hold function must be on). For example, if a trigger hold delay time of 2.0 seconds is defined, the operator must hold the trigger for at least 2 seconds be- fore releasing it in order for the trigger hold function to work. Once the trigger hold func- tion is in effect, the wire feeder will stay On un- til the trigger is pressed and released again.

•There is an additional function built in called ”maximum trigger hold time” which is the maximum length of time the trigger can be held and the trigger hold function still work when the trigger is released (the trigger hold function must be on). The maximum trigger hold time is set at 4.0 seconds after

the trigger hold delay time. For example, if a trigger hold delay time of 2.0 seconds is defined, and the operator held the trigger in for more than 6.0 seconds, the trigger hold function would not be in effect and the wire feeder would stop when the trigger is rele- ased.

•When the Setup push button is pressed again, the menu repeats to the first menu selection of

Trigger Program Select

•If the Setup push button is pressed, the unit allows Trigger Program Select or Trigger Dual Schedule to be enabled or disabled.

The upper display shows “TSEL”. Lower dis- play shows “OFF” or “PROG” or “DUAL”. The Adjust Control is used to select “OFF” or “PROG” or “DUAL”.

Trigger Program Select (PROG) allows the operator to select programs during preflow by clicking the trigger (pulling and releasing the trigger in a maximum of 0.2 seconds). The feeder will switch between any programs that have a minimum of 0.2 seconds of preflow time set in the weld sequence. Any combina- tion of programs may be used. Trigger Pro- gram Select cannot be used while welding or with Dual Schedule.

(Example: If programs 1 and 3 have a mini- mum of 0.2 seconds of preflow time, clicking the trigger will toggle between programs 1 and 3).

Trigger Dual Schedule Select (DUAL) allows the operator to switch between paired sched- ules (programs 1−2, 3−4, 5−6, or 7−8) with the gun trigger, but only while welding. This fea- ture cannot be used with Trigger Hold or Dual Schedule. To end the weld, the trigger must be released for 0.4 seconds.

(Example: when welding with this feature en- abled in program 1, if you release,

Process Select

Process selection indicated by ”PROS” in the upper display is set to either ”VOLT” or ”TRIM” in the lower display. Each program can be selected be be a MIG program indi- cated by ”VOLT” or a pulsing program indi- cated by ”TRIM”.

Range Locks

Range locks are indicated by “LOCK” in the upper display for wire speed or “LOCK” in the lower display for voltage range. In a MIG pro- gram, the voltage range lock ranges from 0 to 10 volts. In a pulse program, the trim range lock ranges from 0 to 100. The wire feed speed range lock ranges from 0 to 250 ipm. Locks are program dependent and wire speed is independent from voltage or trim.

Wire Feed Speed Units

Wire feed speed setting indicated by “WFS” in the upper display is set to “IPM” inches− per−minute or ”MPM” meters−per−minute. This setting is independent of the program se- lected.