Declaration of Conformity for

European Community (CE) Products

NOTE

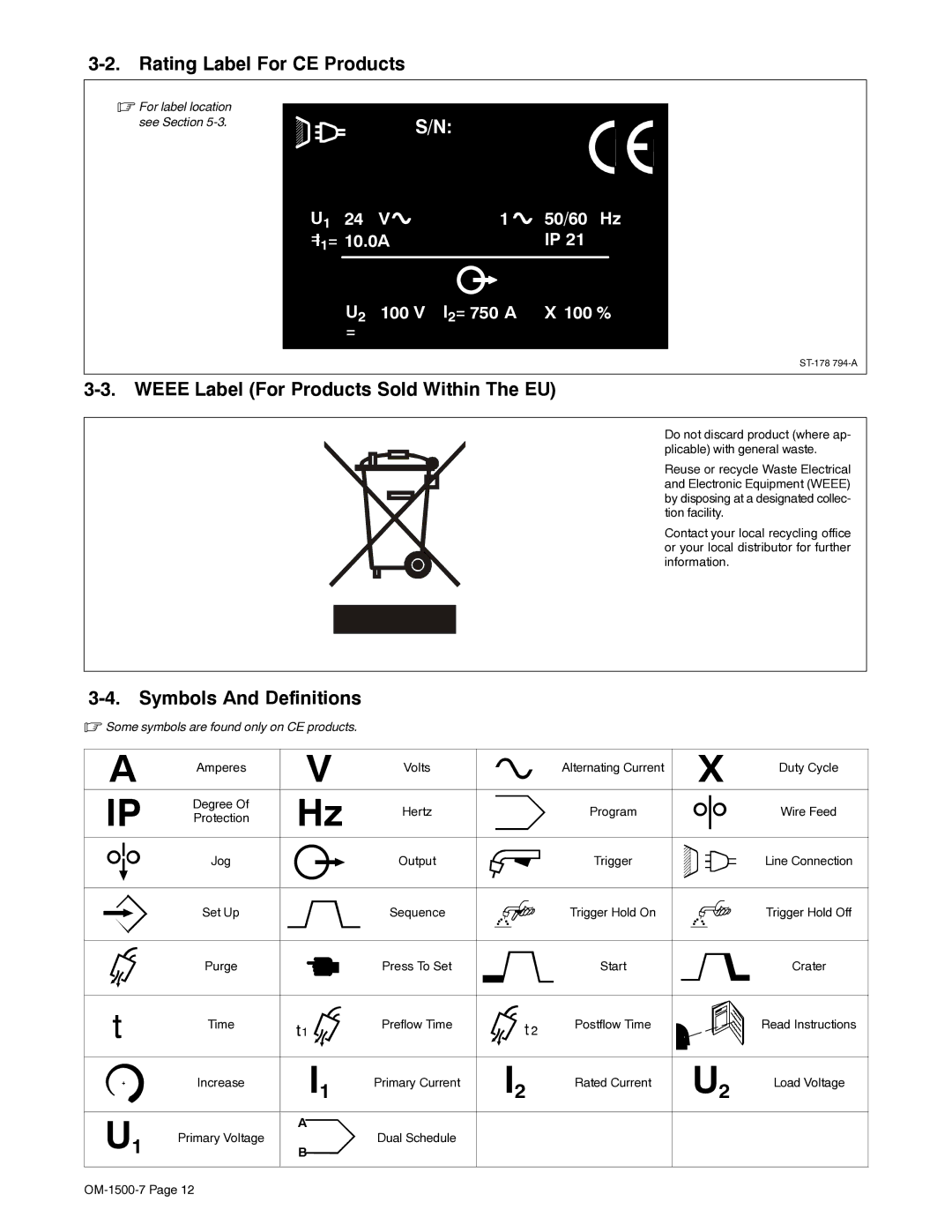

This information is provided for units with CE certification (see rating label on unit).

Manufacturer: | European Contact: |

Miller Electric Mg. Co. | Mr. Danilo Fedolfi, |

1635 W. Spencer St. | Managing Director |

Appleton, WI 54914 USA | ITW Welding Products Italy S.r.l. |

Phone: (920) | Via Privata Iseo 6/E |

| 20098 San Giuliano |

| Milanese, Italy |

| Phone: |

| Fax: 39(02)98290203 |

European Contact Signature: |

|

Declares that the product: |

|

conforms to the following Directives and Standards:

Directives

Low Voltage Directive: 73/23/EEC

Electromagnetic Compatibility (EMC) Directive: 89/336/EEC

Machinery Directives: 98/37/EEC, 91/368/EEC, 92/31/EEC, 133/04, 93/68/EEC

Standards

Arc Welding Equipment − Part 5: Wire Feeders. IEC

Arc Welding Equipment − Part 10: Electromagnetic Compatibility (EMC) Requirements. IEC

Arc Welding Equipment − Part 1: Welding Power Sources. IEC

Degrees Of Protection Provided By Enclosure (IP Code) IEC 60529 Ed. 2.1

Insulation Coordination For Equipment Within

Part 1: Principles, Requirements and Tests: IEC

The product technical file is maintained by the responsible Business Unit(s) located at the manufacturing facility.