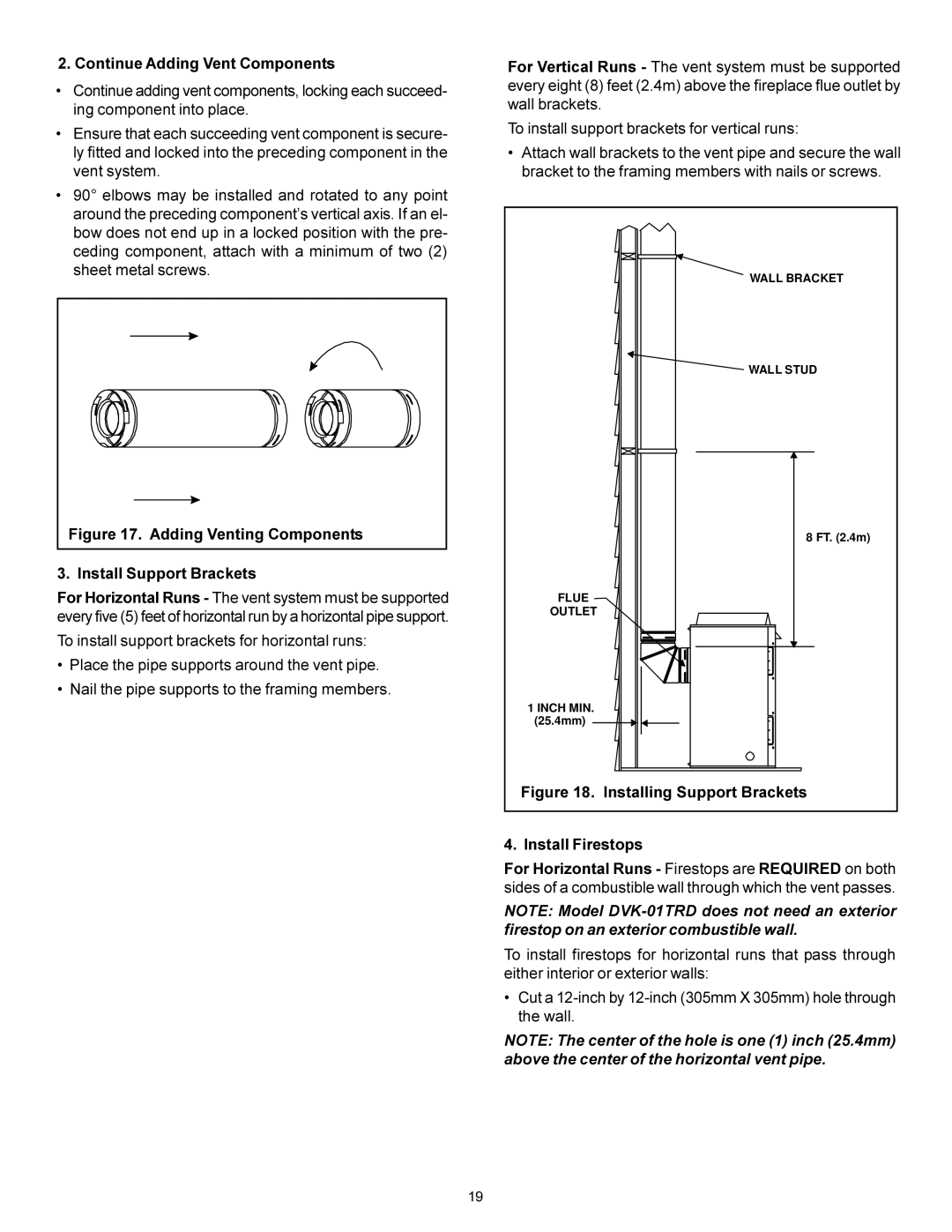

2.Continue Adding Vent Components

•Continue adding vent components, locking each succeed- ing component into place.

•Ensure that each succeeding vent component is secure- ly fitted and locked into the preceding component in the vent system.

•90° elbows may be installed and rotated to any point around the preceding component’s vertical axis. If an el- bow does not end up in a locked position with the pre- ceding component, attach with a minimum of two (2) sheet metal screws.

Figure 17. Adding Venting Components |

3. Install Support Brackets

For Horizontal Runs - The vent system must be supported every five (5) feet of horizontal run by a horizontal pipe support.

To install support brackets for horizontal runs:

•Place the pipe supports around the vent pipe.

•Nail the pipe supports to the framing members.

For Vertical Runs - The vent system must be supported every eight (8) feet (2.4m) above the fireplace flue outlet by wall brackets.

To install support brackets for vertical runs:

•Attach wall brackets to the vent pipe and secure the wall bracket to the framing members with nails or screws.

WALL BRACKET

![]() WALL STUD

WALL STUD

8 FT. (2.4m)

FLUE

OUTLET

1 INCH MIN. (25.4mm)

Figure 18. Installing Support Brackets

4. Install Firestops

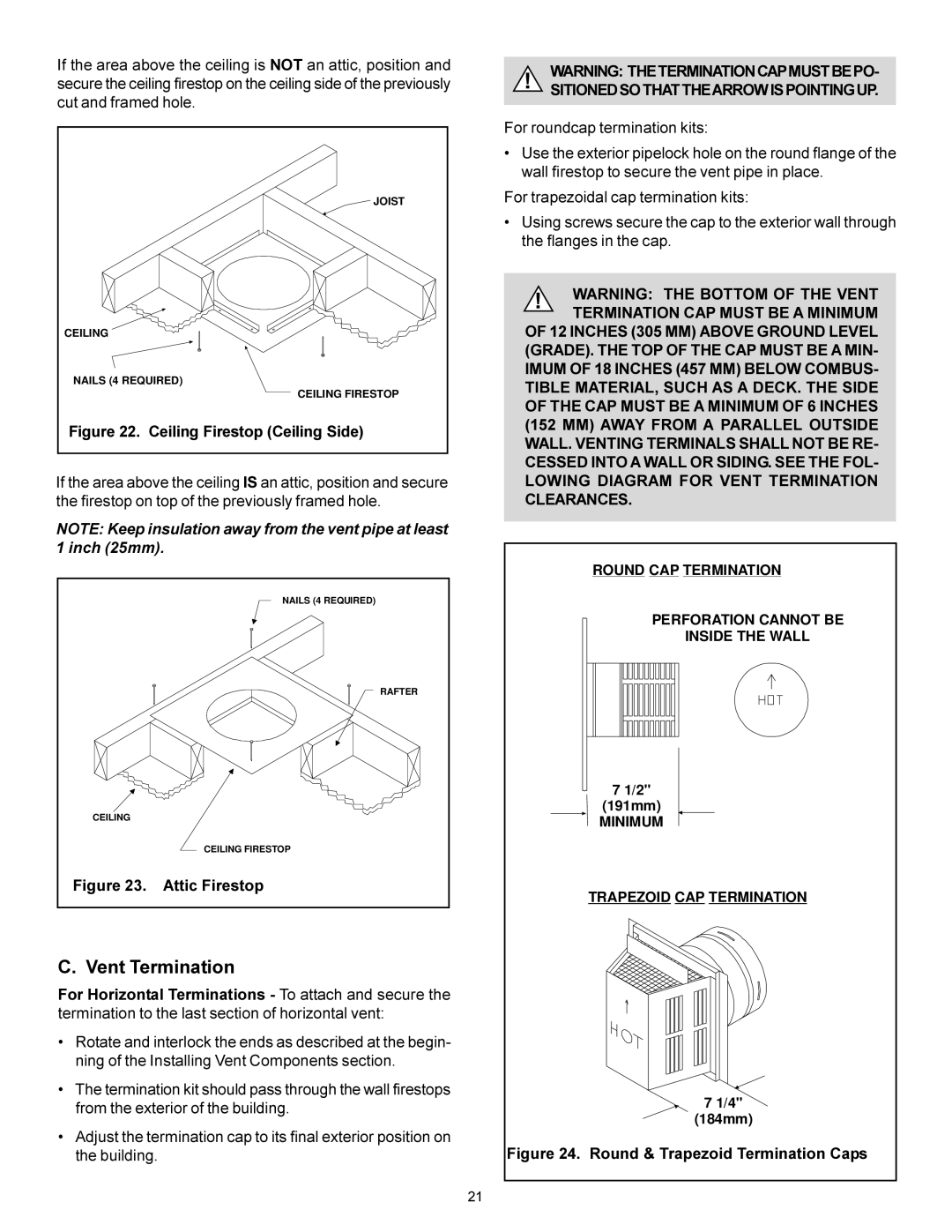

For Horizontal Runs - Firestops are REQUIRED on both sides of a combustible wall through which the vent passes.

NOTE: Model

To install firestops for horizontal runs that pass through either interior or exterior walls:

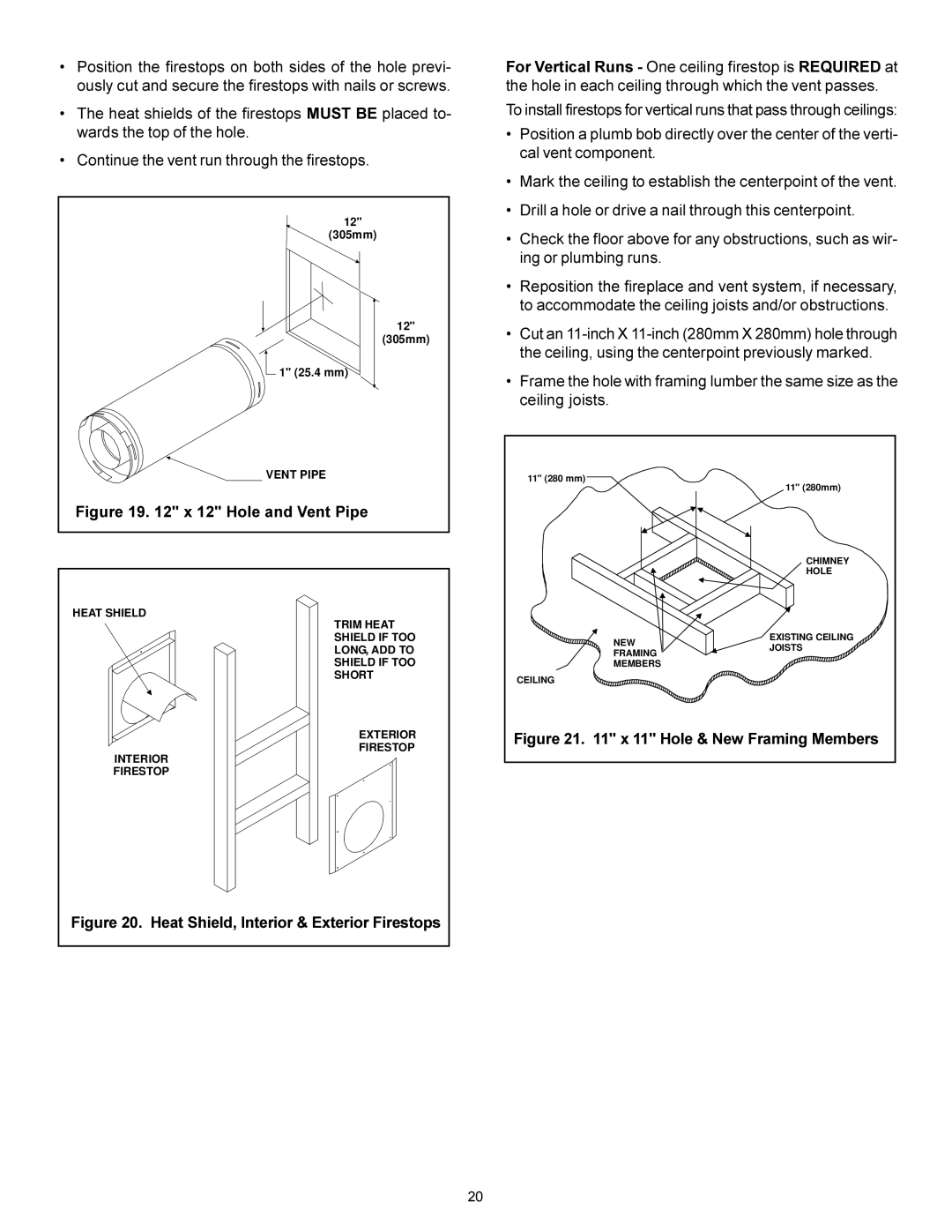

•Cut a

NOTE: The center of the hole is one (1) inch (25.4mm) above the center of the horizontal vent pipe.

19