Documenting Process Calibrator

Calibrating a Process Instrument

∙Go to 100%/Go to 0%

∙Go to 50%

∙As Left

∙Exit Cal

3.Adjust the transmitter output for 4 mA then press the Go to 100% softkey.

4.Adjust the transmitter output for 20 mA.

5.If the span was adjusted in step 4, you must go back and repeat steps 3 and 4 until no more adjustment is required.

6.Now check the transmitter at 50%. If it is within specification, your adjustment is complete. If not, adjust the linearity and begin this procedure again at step 3.

“As Left” Test Run

Proceed as follows to generate and record as left data for the thermocouple temperature transmitter you have just adjusted.

1. Press the As Left softkey to record as left data.

2.Press the Auto Test softkey to begin an automatic sequence through all the test points, or you can step through the tests manually.

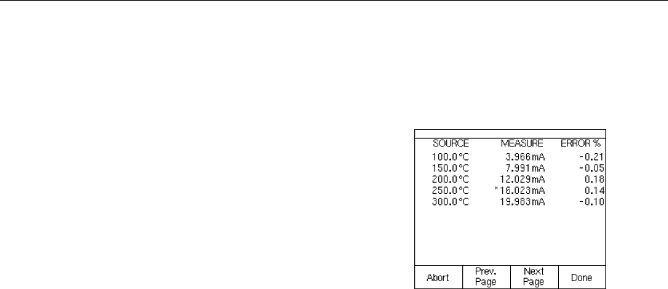

3.When the tests are complete, observe the error summary table, such as the following.

An asterisk (*) next to a measure or source value indicates an unsettled value (gannunciator) when the measurement was taken.

4.If all the results are within specification, as they are this time, press the Done softkey. An entry in memory is made for as left data.

67