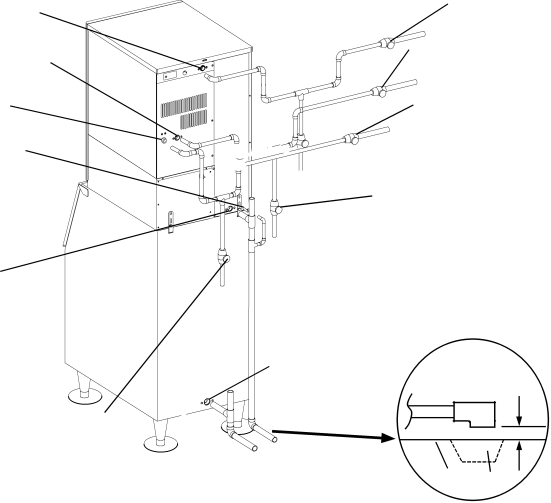

b) Connection to a Closed Loop System

•Condenser water supply inlet is 1/2" female pipe thread (FPT). A minimum of 3/8" OD copper tubing is recommended for the condenser water supply line.

•Condenser return outlet is 3/8" FPT. A minimum of 3/8" OD hard pipe is recommended for the condenser return line.

•

•The water supply to the condenser should not drop below 4 GPM.

•The pressure differential between the condenser water supply inlet and condenser return outlet must be no less than 10 PSIG.

•When using a glycol blend, the solution mixture should be less than 30% glycol.

•In order to maintain the proper high side pressure, the condenser water supply inlet temperature should not drop below 45°F (7°C) and the condenser return outlet temperature must be in the 104°F to 115°F (40°C to 46°C) range. Once the icemaker installation is complete, confirm the condenser return outlet temperature 5 minutes after a freeze cycle starts. If the outlet temperature is not in the proper range, adjust the water‑regulating valve to bring it into range.

Icemaker Water

Supply Inlet

1/2" FPT

Condenser Water

Supply Inlet

1/2" FPT

Condenser

Return Outlet

3/8" FPT

Condensation

Drain Outlet

3/8" OD Stainless

Tube

Icemaker

Drain Outlet

3/4" FPT

Icemaker

Bin

Icemaker Water Supply

Line

Condenser Water Supply Line

Condenser Return Line

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Icemaker Water Supply Line

Icemaker Water Supply Line ![]()

![]()

![]() Drain Valve

Drain Valve

Condenser Water Supply Line

Drain Valve

Separate piping to approved drain. Leave a

Bin Drain Outlet | ||

3/4" FPT | (5 cm) air | |

gap | ||

|

Condenser Return Line

Drain Valve

Fig. 13 |

| Floor | Drain |

|

| ||

| Connection to a Closed Loop System |

|

|

23