OPERATION

OPERATION

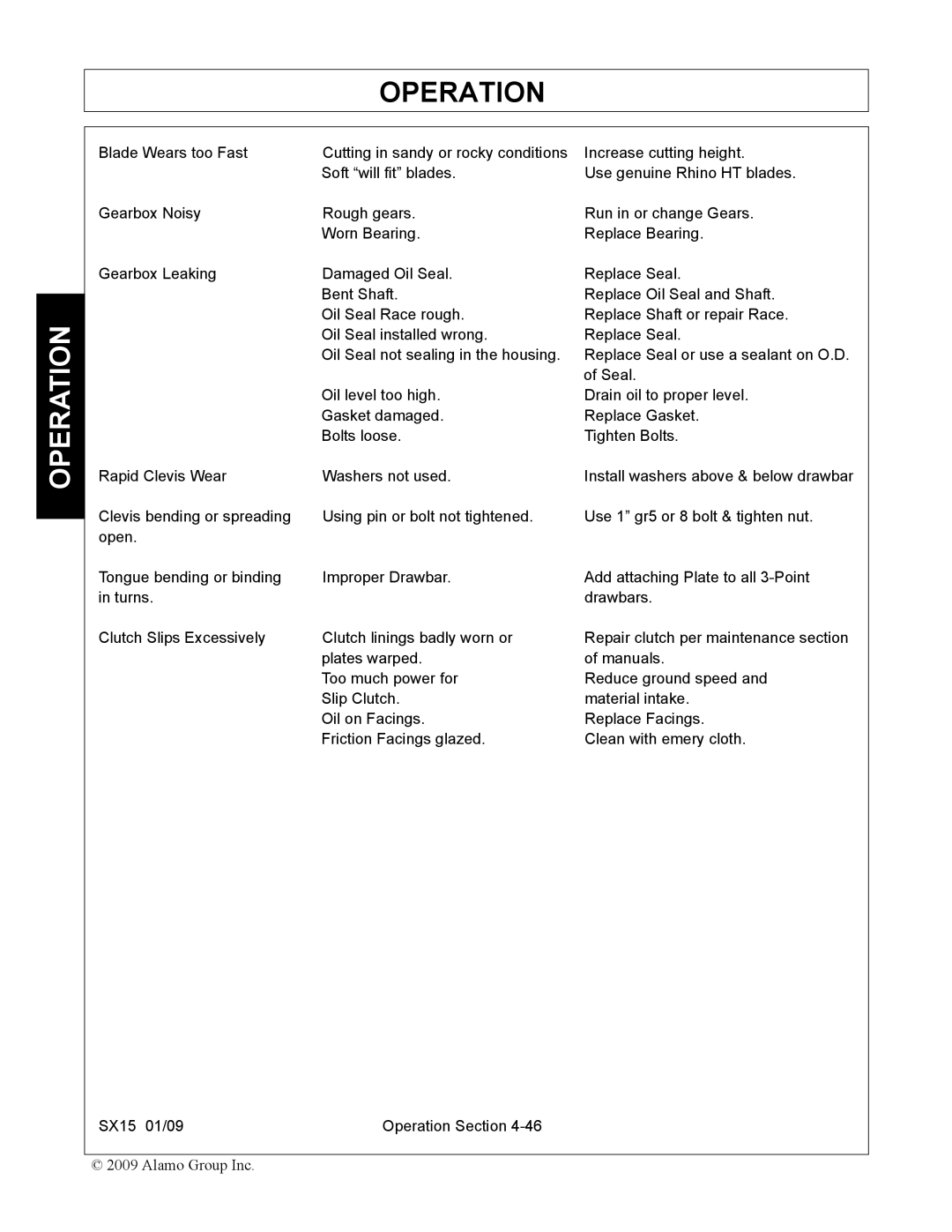

Blade Wears too Fast | Cutting in sandy or rocky conditions | Increase cutting height. |

| Soft “will fit” blades. | Use genuine Rhino HT blades. |

Gearbox Noisy | Rough gears. | Run in or change Gears. |

| Worn Bearing. | Replace Bearing. |

Gearbox Leaking | Damaged Oil Seal. | Replace Seal. |

| Bent Shaft. | Replace Oil Seal and Shaft. |

| Oil Seal Race rough. | Replace Shaft or repair Race. |

| Oil Seal installed wrong. | Replace Seal. |

| Oil Seal not sealing in the housing. | Replace Seal or use a sealant on O.D. |

|

| of Seal. |

| Oil level too high. | Drain oil to proper level. |

| Gasket damaged. | Replace Gasket. |

| Bolts loose. | Tighten Bolts. |

Rapid Clevis Wear | Washers not used. | Install washers above & below drawbar |

Clevis bending or spreading | Using pin or bolt not tightened. | Use 1” gr5 or 8 bolt & tighten nut. |

open. |

|

|

Tongue bending or binding | Improper Drawbar. | Add attaching Plate to all |

in turns. |

| drawbars. |

Clutch Slips Excessively | Clutch linings badly worn or | Repair clutch per maintenance section |

| plates warped. | of manuals. |

| Too much power for | Reduce ground speed and |

| Slip Clutch. | material intake. |

| Oil on Facings. | Replace Facings. |

| Friction Facings glazed. | Clean with emery cloth. |

SX15 01/09 | Operation Section |

© 2009 Alamo Group Inc.