OPERATION

OPERATION

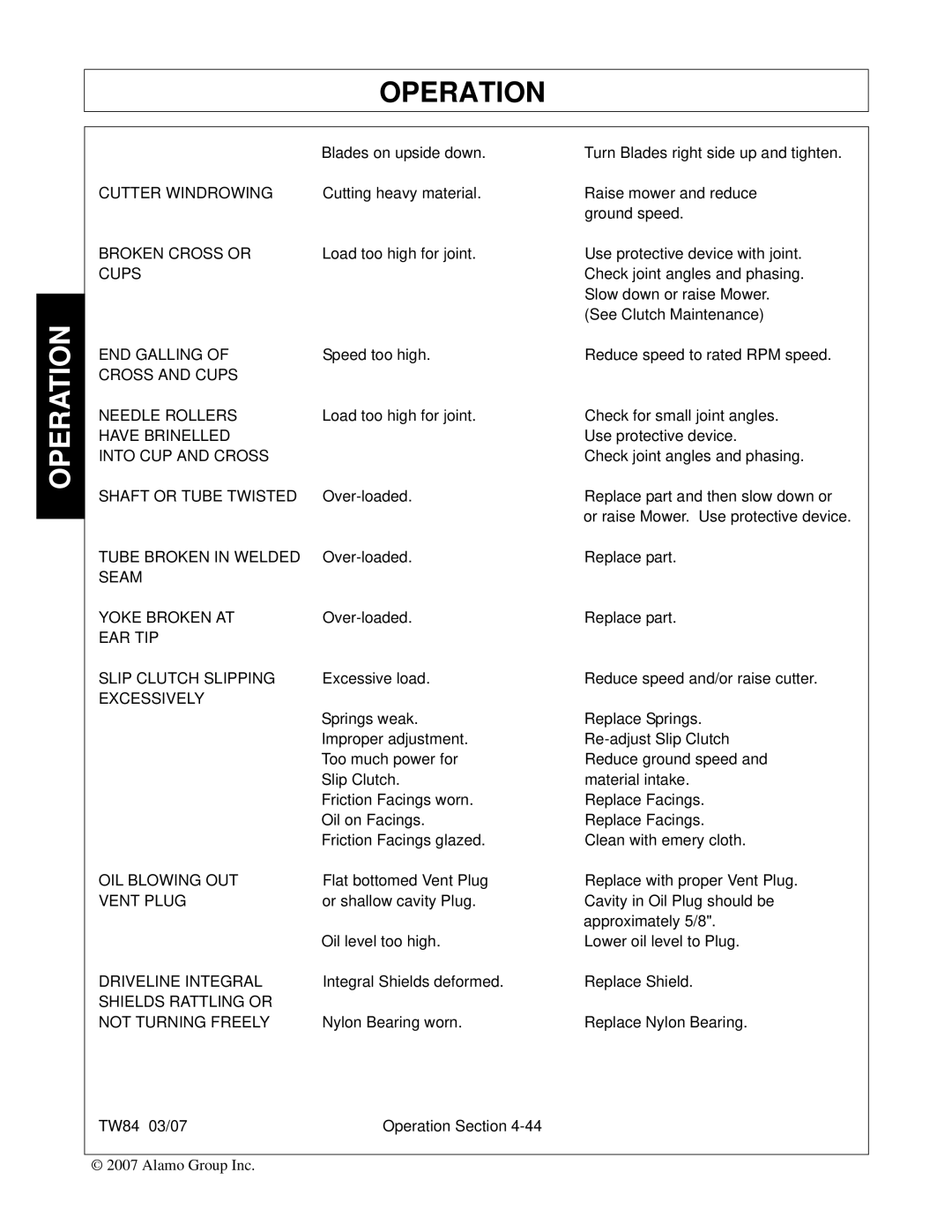

| Blades on upside down. | Turn Blades right side up and tighten. |

CUTTER WINDROWING | Cutting heavy material. | Raise mower and reduce |

|

| ground speed. |

BROKEN CROSS OR | Load too high for joint. | Use protective device with joint. |

CUPS |

| Check joint angles and phasing. |

|

| Slow down or raise Mower. |

|

| (See Clutch Maintenance) |

END GALLING OF | Speed too high. | Reduce speed to rated RPM speed. |

CROSS AND CUPS |

|

|

NEEDLE ROLLERS | Load too high for joint. | Check for small joint angles. |

HAVE BRINELLED |

| Use protective device. |

INTO CUP AND CROSS |

| Check joint angles and phasing. |

SHAFT OR TUBE TWISTED | Replace part and then slow down or | |

|

| or raise Mower. Use protective device. |

TUBE BROKEN IN WELDED | Replace part. | |

SEAM |

|

|

YOKE BROKEN AT | Replace part. | |

EAR TIP |

|

|

SLIP CLUTCH SLIPPING | Excessive load. | Reduce speed and/or raise cutter. |

EXCESSIVELY | Springs weak. | Replace Springs. |

| ||

| Improper adjustment. | |

| Too much power for | Reduce ground speed and |

| Slip Clutch. | material intake. |

| Friction Facings worn. | Replace Facings. |

| Oil on Facings. | Replace Facings. |

| Friction Facings glazed. | Clean with emery cloth. |

OIL BLOWING OUT | Flat bottomed Vent Plug | Replace with proper Vent Plug. |

VENT PLUG | or shallow cavity Plug. | Cavity in Oil Plug should be |

|

| approximately 5/8". |

| Oil level too high. | Lower oil level to Plug. |

DRIVELINE INTEGRAL | Integral Shields deformed. | Replace Shield. |

SHIELDS RATTLING OR |

|

|

NOT TURNING FREELY | Nylon Bearing worn. | Replace Nylon Bearing. |

TW84 03/07 | Operation Section |

© 2007 Alamo Group Inc.