OPERATION

Cutting Height Adjustment

1.Using the tractor hydraulics, raise the mowers off the ground and support under it with secure blocking so not to let the mower drift down during maintenance.

2.Holding wheel and yoke assembly up, remove

ROLLER ADJUSTMENT

Place roller bracketst in lowest position for cutting heights 5” to approximately 3”. Place in highest position for 1” approximately

8. DRIVELINE ATTACHMENT

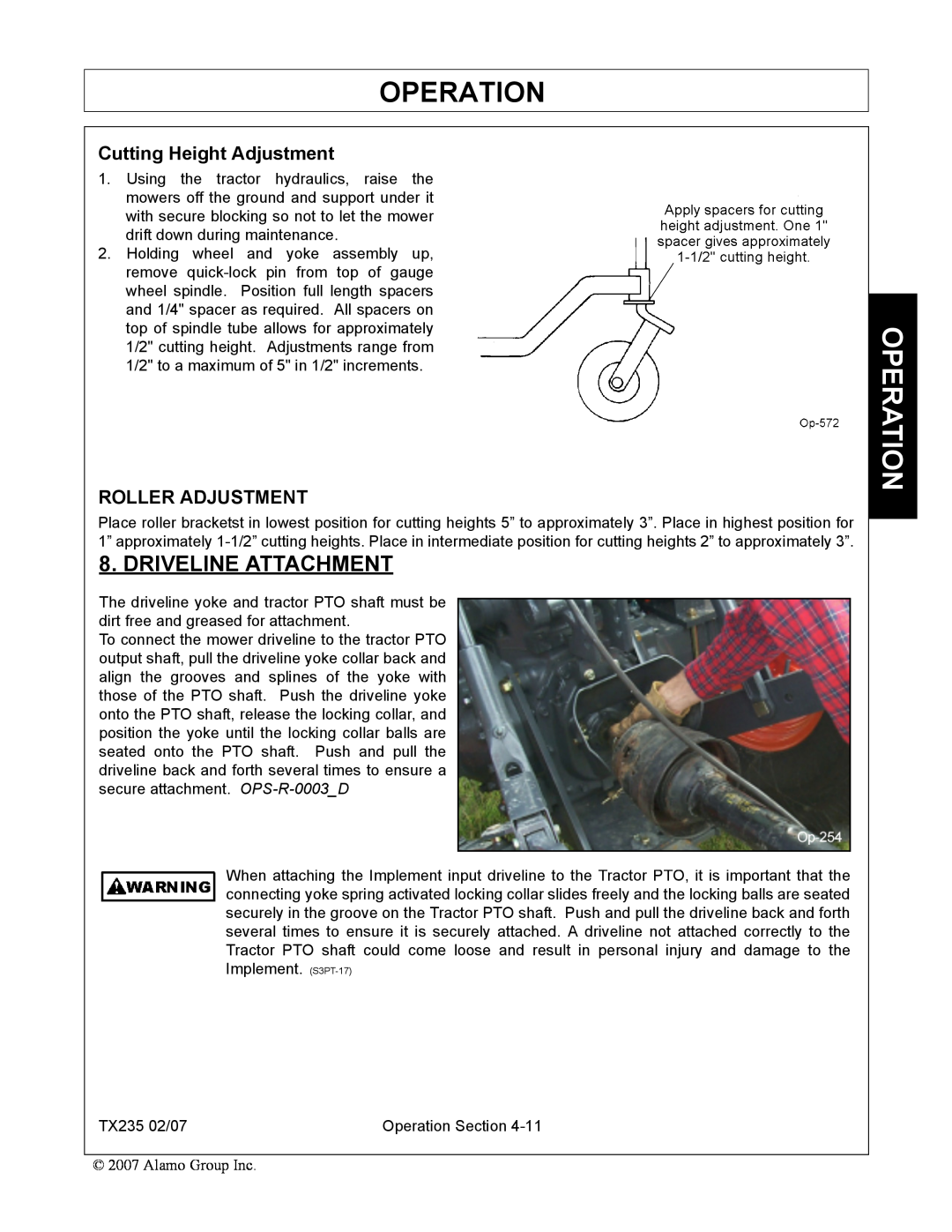

The driveline yoke and tractor PTO shaft must be dirt free and greased for attachment.

To connect the mower driveline to the tractor PTO output shaft, pull the driveline yoke collar back and align the grooves and splines of the yoke with those of the PTO shaft. Push the driveline yoke onto the PTO shaft, release the locking collar, and position the yoke until the locking collar balls are seated onto the PTO shaft. Push and pull the driveline back and forth several times to ensure a secure attachment.

When attaching the Implement input driveline to the Tractor PTO, it is important that the connecting yoke spring activated locking collar slides freely and the locking balls are seated securely in the groove on the Tractor PTO shaft. Push and pull the driveline back and forth several times to ensure it is securely attached. A driveline not attached correctly to the Tractor PTO shaft could come loose and result in personal injury and damage to the Implement.

TX235 02/07 | Operation Section |

© 2007 Alamo Group Inc.

OPERATION