3.Refer to Figure 9 and Table 4 to set the drill depth gauge.

4.Drill the holes to the set depth. Refer to Table 4.

5.Use compressed air or a squeeze bulb to remove debris from each hole.

6.Fill half the hole depth with an industry accepted adhesive anchoring system.

7.Insert bolt until it reaches the bottom of the hole and 1.5 inches (38 mm) of the bolt extends above the base frame. Refer to Figure 10.

8.Allow adhesive around the bolt to cure properly.

9.Position base frame over anchoring bolts.

10.Raise and level the base frame .5 inch (13 mm) off the floor on three points, using spacers such as nut fasteners.

11.Fill the space between the base frame and the floor with a good quality

12.Position washers and locknuts on bolts and finger tighten nuts to base frame.

13.Before grout sets completely, make a drain opening in the grouting at the rear of the base frame with a stiff piece of wire. This opening should be approximately .5 inch (13 mm) wide to allow any surface water

14.Allow machine grout to set, but not cure.

15.Remove the spacers carefully, allowing the base frame to settle into the wet grout.

16.Tighten nuts by even increments – one after the other using the specified torque – until all are tightened evenly and the base frame is fastened securely to the floor. Refer to Table 4.

Installation

17.Position the machine over the base frame, aligning the mounting holes on the machine with the corresponding holes on the frame.

18.Install a bolt, lockwasher, and nut in each mounting hole. Use 5/8 inch – 18 x 2.00 grade 5 mounting bolts with 5/8 inch – 18 grade B nuts and 5/8 inch lockwashers.

19.Hand tighten each nut.

20.Tighten the two rear nuts two turns.

21.Tighten the two front nuts two turns.

22.On 30, 40 and 60 models, tighten the two middle nuts firmly.

23.Tighten the two front nuts firmly; tighten the two rear nuts firmly.

NOTE: Check and retighten the locknuts after five to ten days of operation and every three months thereafter.

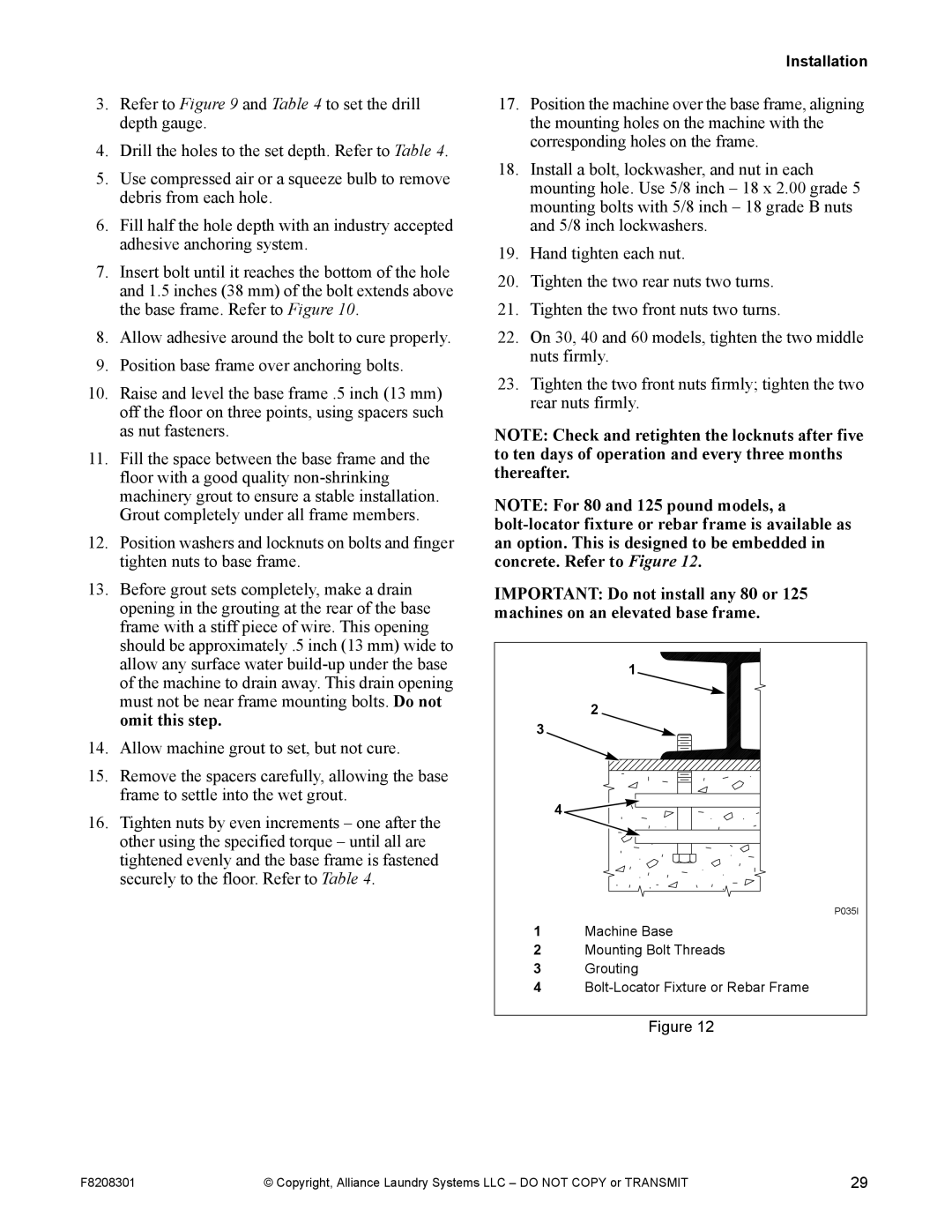

NOTE: For 80 and 125 pound models, a

IMPORTANT: Do not install any 80 or 125 machines on an elevated base frame.

1 |

2

3

4 |

P035I

1Machine Base

2Mounting Bolt Threads

3Grouting

4

Figure 12

F8208301 | © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT | 29 |