Periodic maintenance is done to check the tool and to minimize down time. These checks are done based on hours of operation and operating conditions. Operating condition can vary depending on the work surface and job being preformed. If the tool is not used for a long period of time the carbon brushes should be checked and the commutator cleaned, before putting the tool back into operation.

BEARINGS AND GEARS

BEARINGS AND GEARS

To minimize your tool’s down time and expensive tool repairs, it is recommended to send the tool back to an Alpha® Repair Center after about 300 to 400 hours of operation or every second carbon brush set change. The bearings should be replaced and the gears should be checked. If your tool starts to sound differently, this could be an indication of a worn bearing; continuing to use the tool in this condition could result in over heating or motor failure.

CARBON BRUSH REPLACEMENT

CARBON BRUSH REPLACEMENT

Carbon brushes wear out over time, based on the polisher usage. If a carbon brush is worn out, it may cause the motor to malfunction or fail to run. Whenever the length of the carbon brush reaches the wear limit, replace with a new set.

NOTE - To maintain even wear, both brushes should be replaced at the same time.

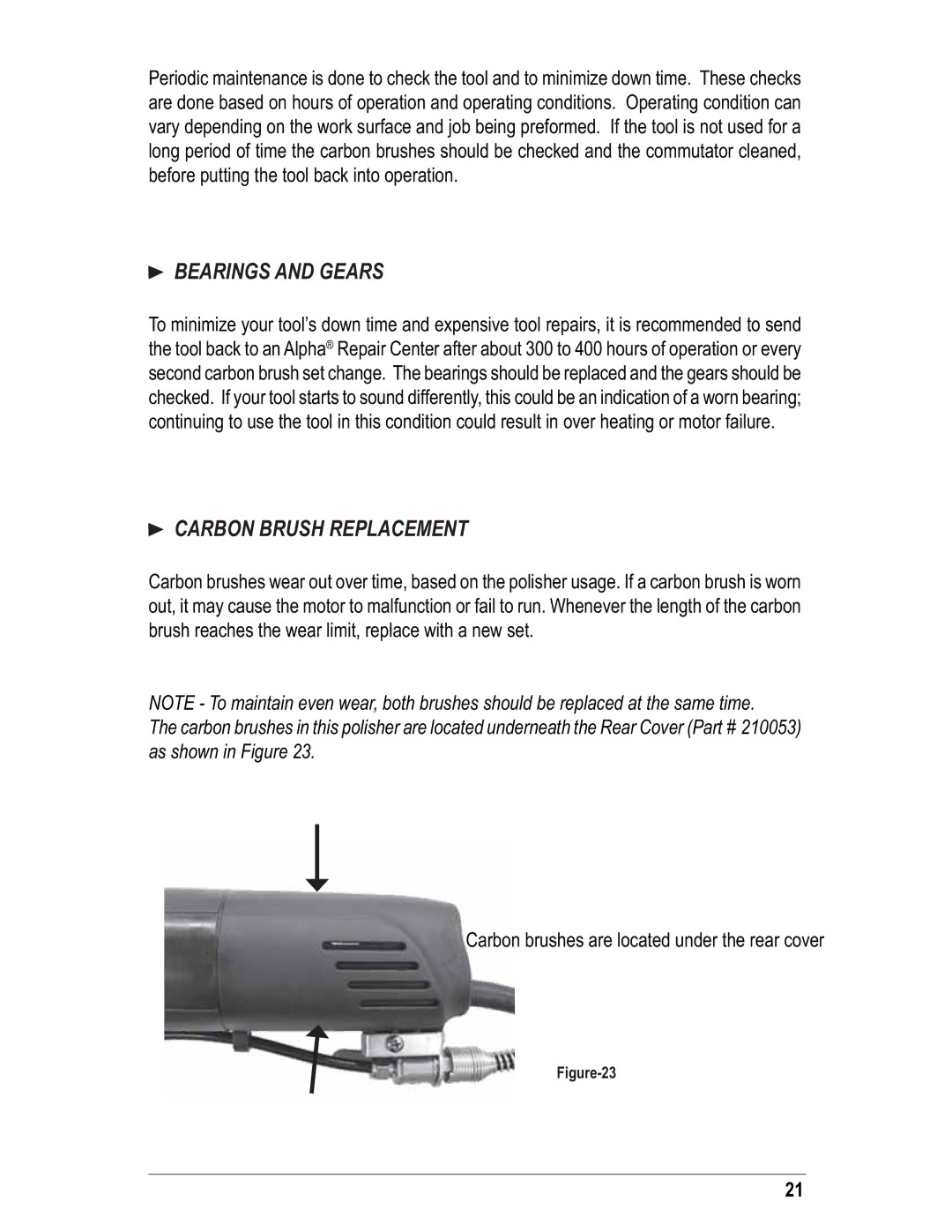

The carbon brushes in this polisher are located underneath the Rear Cover (Part # 210053) as shown in Figure 23.

Carbon brushes are located under the rear cover

21