SECTION II

Routine Maintenance

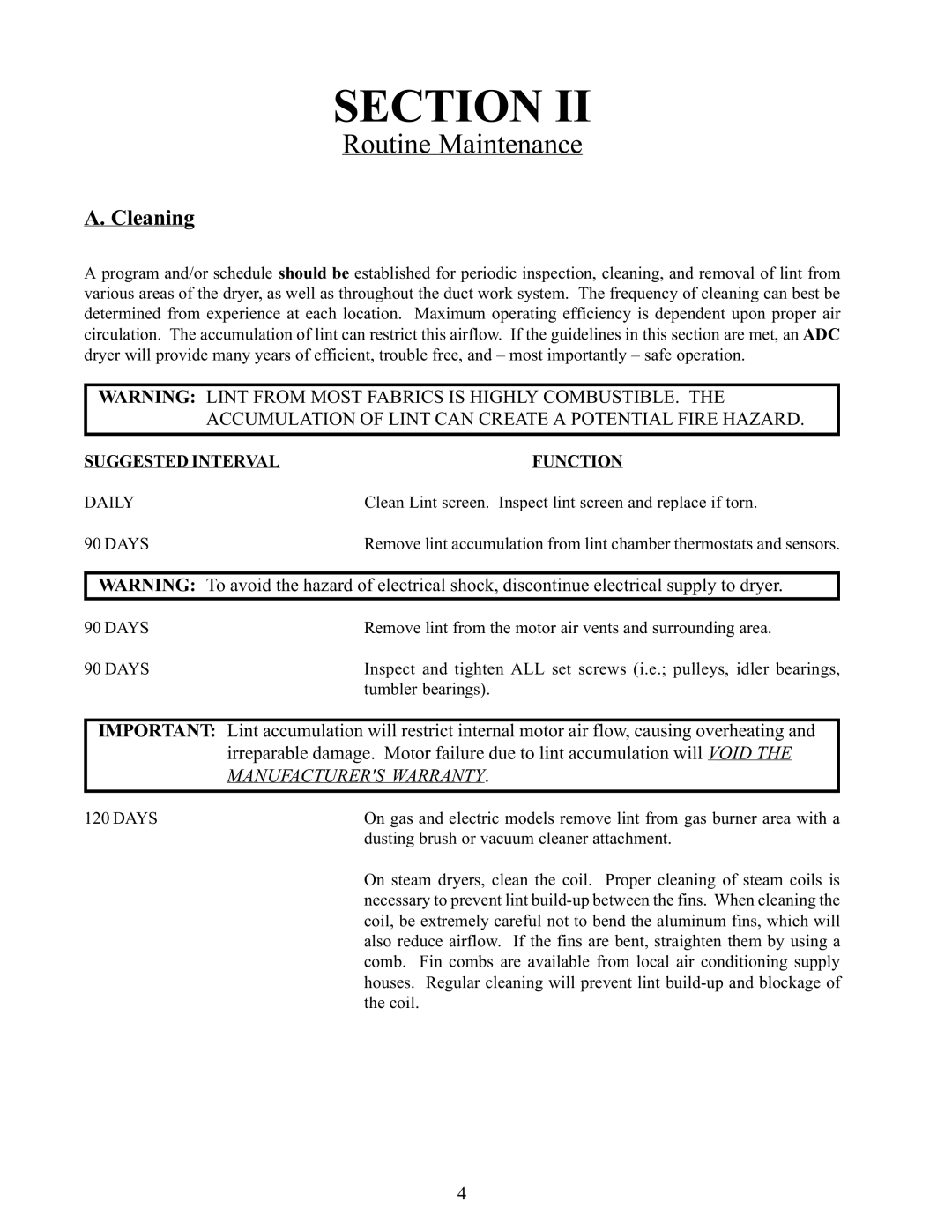

A. Cleaning

A program and/or schedule should be established for periodic inspection, cleaning, and removal of lint from various areas of the dryer, as well as throughout the duct work system. The frequency of cleaning can best be determined from experience at each location. Maximum operating efficiency is dependent upon proper air circulation. The accumulation of lint can restrict this airflow. If the guidelines in this section are met, an ADC dryer will provide many years of efficient, trouble free, and – most importantly – safe operation.

WARNING: LINT FROM MOST FABRICS IS HIGHLY COMBUSTIBLE. THE ACCUMULATION OF LINT CAN CREATE A POTENTIAL FIRE HAZARD.

SUGGESTED INTERVAL | FUNCTION |

DAILY | Clean Lint screen. Inspect lint screen and replace if torn. |

90 DAYS | Remove lint accumulation from lint chamber thermostats and sensors. |

WARNING: To avoid the hazard of electrical shock, discontinue electrical supply to dryer.

90 DAYS | Remove lint from the motor air vents and surrounding area. |

90 DAYS | Inspect and tighten ALL set screws (i.e.; pulleys, idler bearings, |

| tumbler bearings). |

IMPORTANT: Lint accumulation will restrict internal motor air flow, causing overheating and irreparable damage. Motor failure due to lint accumulation will VOID THE MANUFACTURER'S WARRANTY.

120 DAYS | On gas and electric models remove lint from gas burner area with a |

| dusting brush or vacuum cleaner attachment. |

| On steam dryers, clean the coil. Proper cleaning of steam coils is |

| necessary to prevent lint |

| coil, be extremely careful not to bend the aluminum fins, which will |

| also reduce airflow. If the fins are bent, straighten them by using a |

| comb. Fin combs are available from local air conditioning supply |

| houses. Regular cleaning will prevent lint |

| the coil. |

4