ENVIRONMENTAL

CONSIDERATIONS

The MagnaPLUS generator is designed for

WIRING CONNECTIONS

Wiring of the generator and accessories should be done in accordance with good electrical practices. Follow government, industry and association standards.

The generator conduit box construction allows cable entry from multiple sides. A hole saw or other appropriate tool may be used to provide for conduit entrance. Protect the interior of the generator from shavings when drilling or sawing. An approved connector must be used in conjunction

with the conduit. To minimize the transmission of vibration, it is essential that flexible conduit be used for all electrical entrance to the generator conduit box.

All MagnaPLUS generators are equipped with link boards (terminal strips) for both internal and external connections. All connections made to the studs of the link board should be made with high quality ring terminals. Ring terminal sizes are 6 mm (280 Series Frames) and 10 mm (360 and 430 Series Frames). Torque link board connections to the following specifications: 280 frame

Refer to the connection diagram supplied with the generator and / or the proper diagrams shown in this manual. Install all

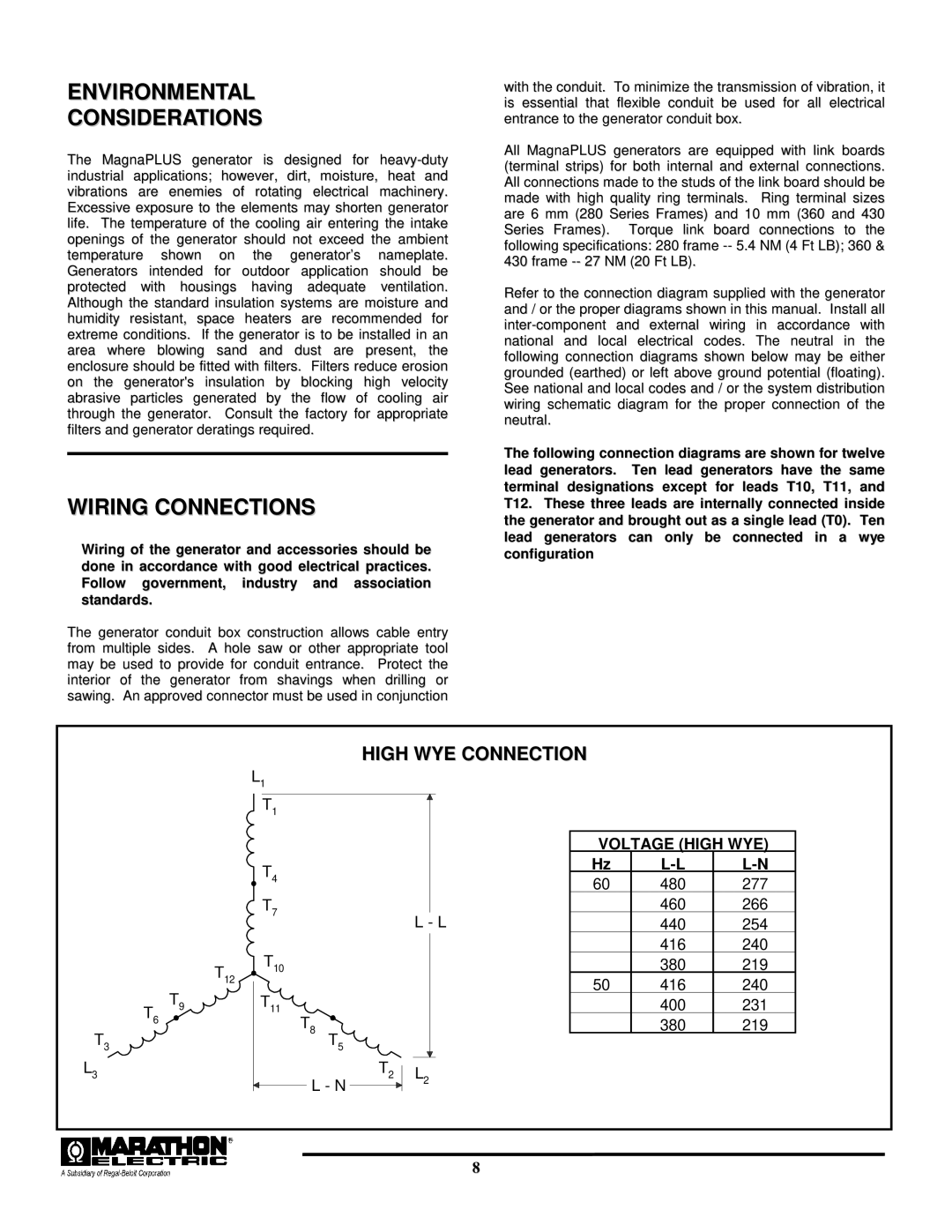

The following connection diagrams are shown for twelve lead generators. Ten lead generators have the same terminal designations except for leads T10, T11, and T12. These three leads are internally connected inside the generator and brought out as a single lead (T0). Ten lead generators can only be connected in a wye configuration

HIGH WYE CONNECTION

L1

|

| T1 |

|

|

|

|

|

|

|

| VOLTAGE (HIGH WYE) | ||

|

| T4 |

| Hz | ||

|

|

| 60 | 480 | 277 | |

|

|

|

| |||

|

| T7 |

| L - L | 460 | 266 |

|

|

|

| 440 | 254 | |

|

| T10 |

|

| 416 | 240 |

| T12 |

|

| 380 | 219 | |

|

|

| 50 | 416 | 240 | |

T9 |

| T11 |

| |||

|

|

| 400 | 231 | ||

T6 |

|

| T |

| 380 | 219 |

T |

|

| 8 T |

|

|

|

3 |

|

| 5 |

|

|

|

L3 |

|

|

| T2 L |

|

|

|

|

| L - N | 2 |

|

|

|

|

|

|

|

| |

8