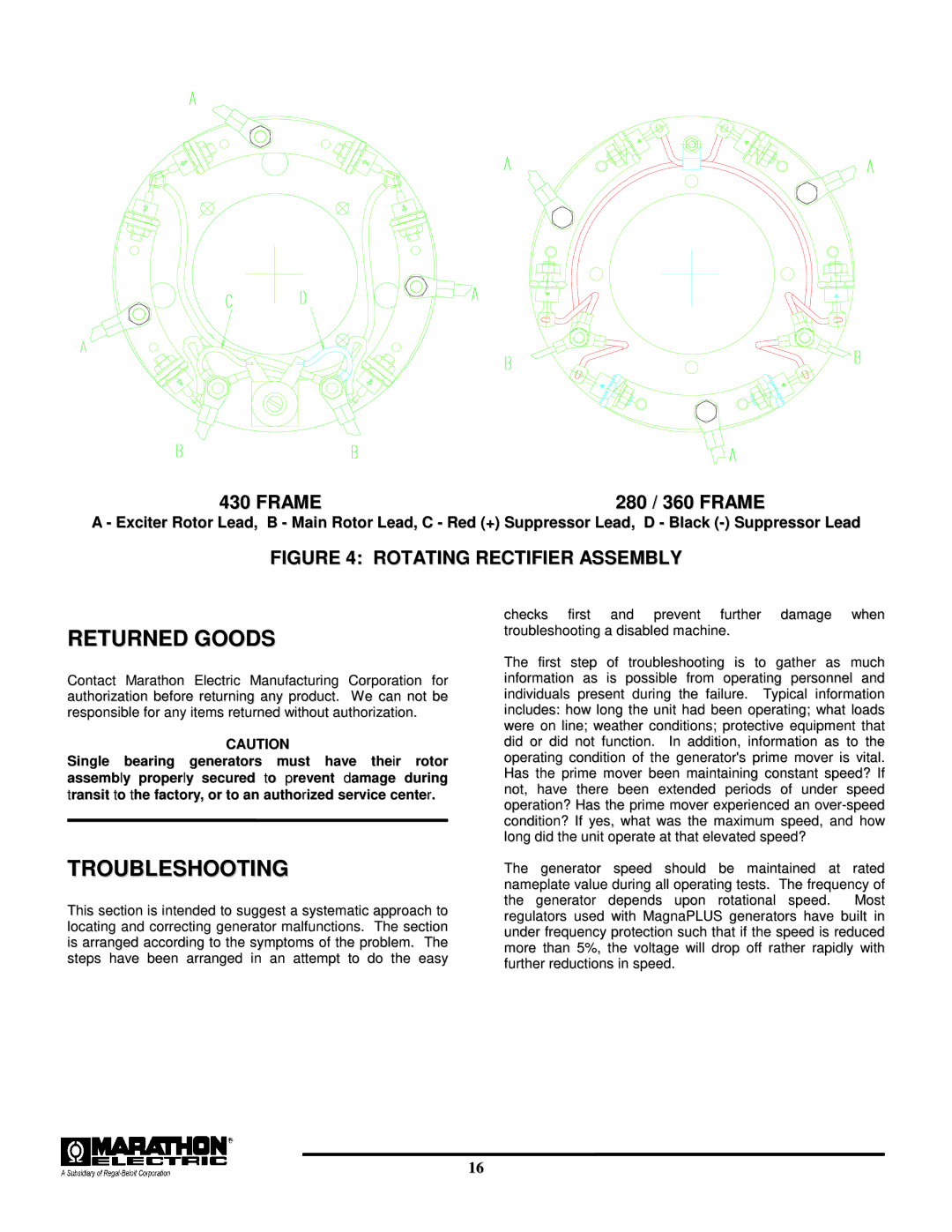

430 FRAME | 280 / 360 FRAME |

A - Exciter Rotor Lead, B - Main Rotor Lead, C - Red (+) Suppressor Lead, D - Black

FIGURE 4: ROTATING RECTIFIER ASSEMBLY

RETURNED GOODS

checks first and prevent further damage when troubleshooting a disabled machine.

Contact Marathon Electric Manufacturing Corporation for authorization before returning any product. We can not be responsible for any items returned without authorization.

CAUTION

Single bearing generators must have their rotor assembly properly secured to prevent damage during transit to the factory, or to an authorized service center.

The first step of troubleshooting is to gather as much information as is possible from operating personnel and individuals present during the failure. Typical information includes: how long the unit had been operating; what loads were on line; weather conditions; protective equipment that did or did not function. In addition, information as to the operating condition of the generator's prime mover is vital. Has the prime mover been maintaining constant speed? If not, have there been extended periods of under speed operation? Has the prime mover experienced an

TROUBLESHOOTING

This section is intended to suggest a systematic approach to locating and correcting generator malfunctions. The section is arranged according to the symptoms of the problem. The steps have been arranged in an attempt to do the easy

The generator speed should be maintained at rated nameplate value during all operating tests. The frequency of the generator depends upon rotational speed. Most regulators used with MagnaPLUS generators have built in under frequency protection such that if the speed is reduced more than 5%, the voltage will drop off rather rapidly with further reductions in speed.

16