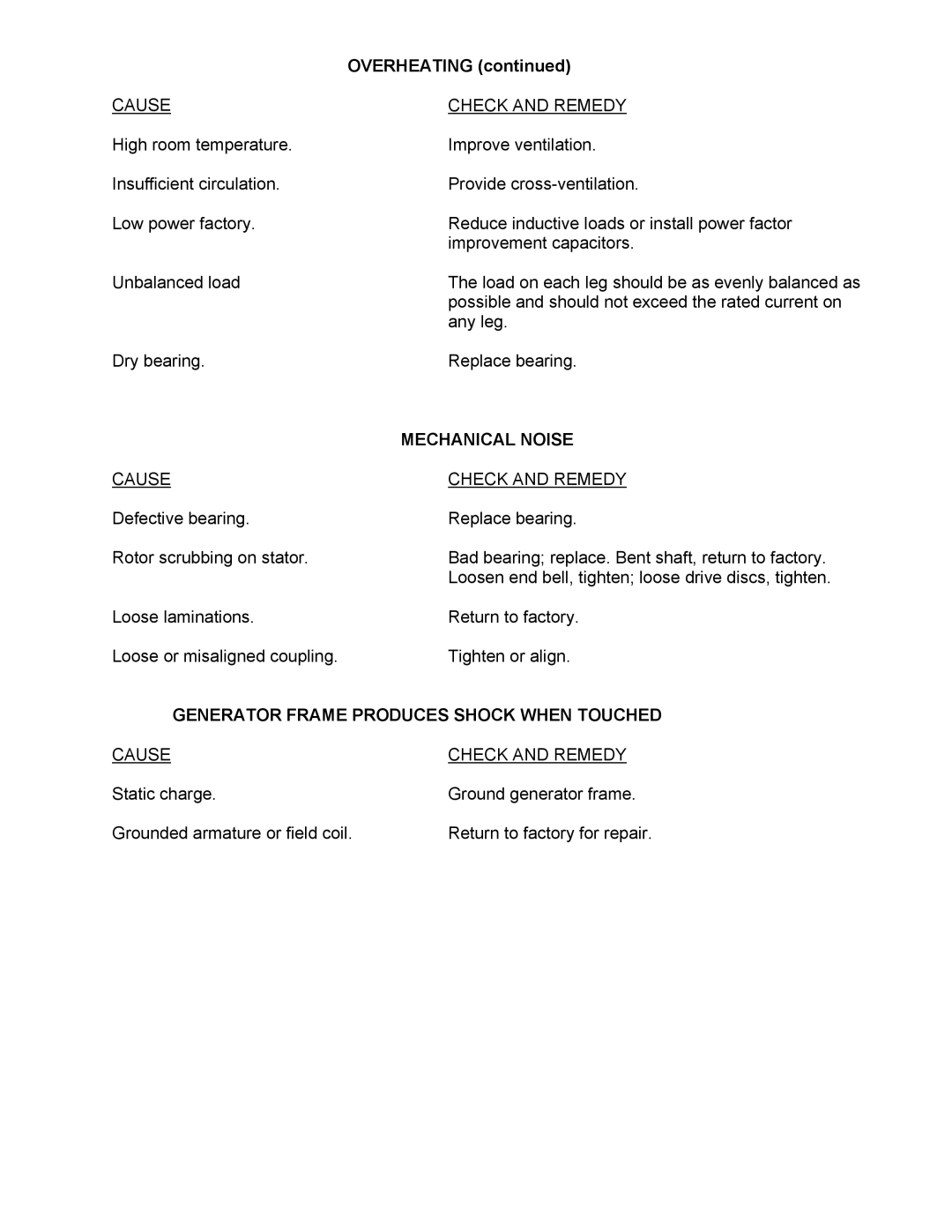

OVERHEATING (continued) | |

CAUSE | CHECK AND REMEDY |

High room temperature. | Improve ventilation. |

Insufficient circulation. | Provide |

Low power factory. | Reduce inductive loads or install power factor |

| improvement capacitors. |

Unbalanced load | The load on each leg should be as evenly balanced as |

| possible and should not exceed the rated current on |

| any leg. |

Dry bearing. | Replace bearing. |

| MECHANICAL NOISE |

CAUSE | CHECK AND REMEDY |

Defective bearing. | Replace bearing. |

Rotor scrubbing on stator. | Bad bearing; replace. Bent shaft, return to factory. |

| Loosen end bell, tighten; loose drive discs, tighten. |

Loose laminations. | Return to factory. |

Loose or misaligned coupling. | Tighten or align. |

GENERATOR FRAME PRODUCES SHOCK WHEN TOUCHED | |

CAUSE | CHECK AND REMEDY |

Static charge. | Ground generator frame. |

Grounded armature or field coil. | Return to factory for repair. |

Page 39

Image 39