MAINTENANCE SCHEDULE

Following are the instructions for performing some of the recommended maintenance. Unit inspection and adjustment should be performed by a competent technician.

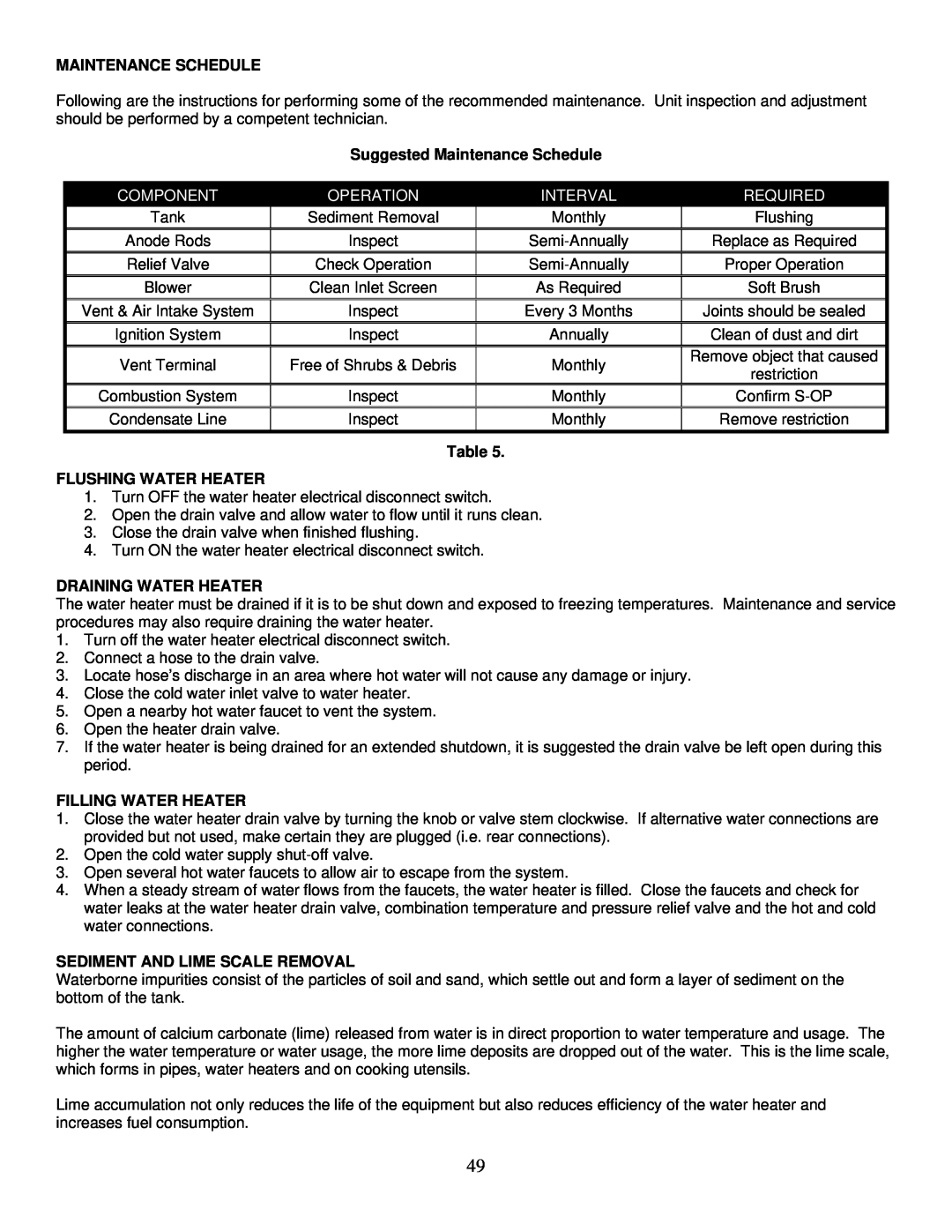

Suggested Maintenance Schedule

| COMPONENT | OPERATION | INTERVAL |

| Tank | Sediment Removal | Monthly |

| Anode Rods | Inspect | |

| Relief Valve | Check Operation | |

| Blower | Clean Inlet Screen | As Required |

| Vent & Air Intake System | Inspect | Every 3 Months |

| Ignition System | Inspect | Annually |

| Vent Terminal | Free of Shrubs & Debris | Monthly |

|

|

|

|

REQUIRED

Flushing

Replace as Required

Proper Operation

Soft Brush

Joints should be sealed Clean of dust and dirt

Remove object that caused

restriction

Combustion System | Inspect | Monthly |

Condensate Line | Inspect | Monthly |

|

|

|

Confirm

Remove restriction

Table 5.

FLUSHING WATER HEATER

1.Turn OFF the water heater electrical disconnect switch.

2.Open the drain valve and allow water to flow until it runs clean.

3.Close the drain valve when finished flushing.

4.Turn ON the water heater electrical disconnect switch.

DRAINING WATER HEATER

The water heater must be drained if it is to be shut down and exposed to freezing temperatures. Maintenance and service procedures may also require draining the water heater.

1.Turn off the water heater electrical disconnect switch.

2.Connect a hose to the drain valve.

3.Locate hose’s discharge in an area where hot water will not cause any damage or injury.

4.Close the cold water inlet valve to water heater.

5.Open a nearby hot water faucet to vent the system.

6.Open the heater drain valve.

7.If the water heater is being drained for an extended shutdown, it is suggested the drain valve be left open during this period.

FILLING WATER HEATER

1.Close the water heater drain valve by turning the knob or valve stem clockwise. If alternative water connections are provided but not used, make certain they are plugged (i.e. rear connections).

2.Open the cold water supply

3.Open several hot water faucets to allow air to escape from the system.

4.When a steady stream of water flows from the faucets, the water heater is filled. Close the faucets and check for water leaks at the water heater drain valve, combination temperature and pressure relief valve and the hot and cold water connections.

SEDIMENT AND LIME SCALE REMOVAL

Waterborne impurities consist of the particles of soil and sand, which settle out and form a layer of sediment on the bottom of the tank.

The amount of calcium carbonate (lime) released from water is in direct proportion to water temperature and usage. The higher the water temperature or water usage, the more lime deposits are dropped out of the water. This is the lime scale, which forms in pipes, water heaters and on cooking utensils.

Lime accumulation not only reduces the life of the equipment but also reduces efficiency of the water heater and increases fuel consumption.

49