BSPP Generator

GENERAL MAINTENANCE RECOMMENDATIONS

The Owner/Operator is responsible for making sure that all periodic maintenance tasks are completed on a timely basis; that all discrepancies are corrected; and that the unit is kept clean and properly stored. NEVER operate a

damaged or defective generator.

Engine Maintenance

See engine owner’s manual for instructions.

![]() CAUTION

CAUTION

Avoid prolonged or repeated skin contact with used motor oil.

•Used motor oil has been shown to cause skin cancer in certain laboratory animals.

•Thoroughly wash exposed areas with soap and water.

![]() WARNING

WARNING

Unintentional sparking can result in fire or electric shock.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR GENERATOR

•Disconnect the spark plug wire from the spark plug and place the wire where it cannot contact spark plug.

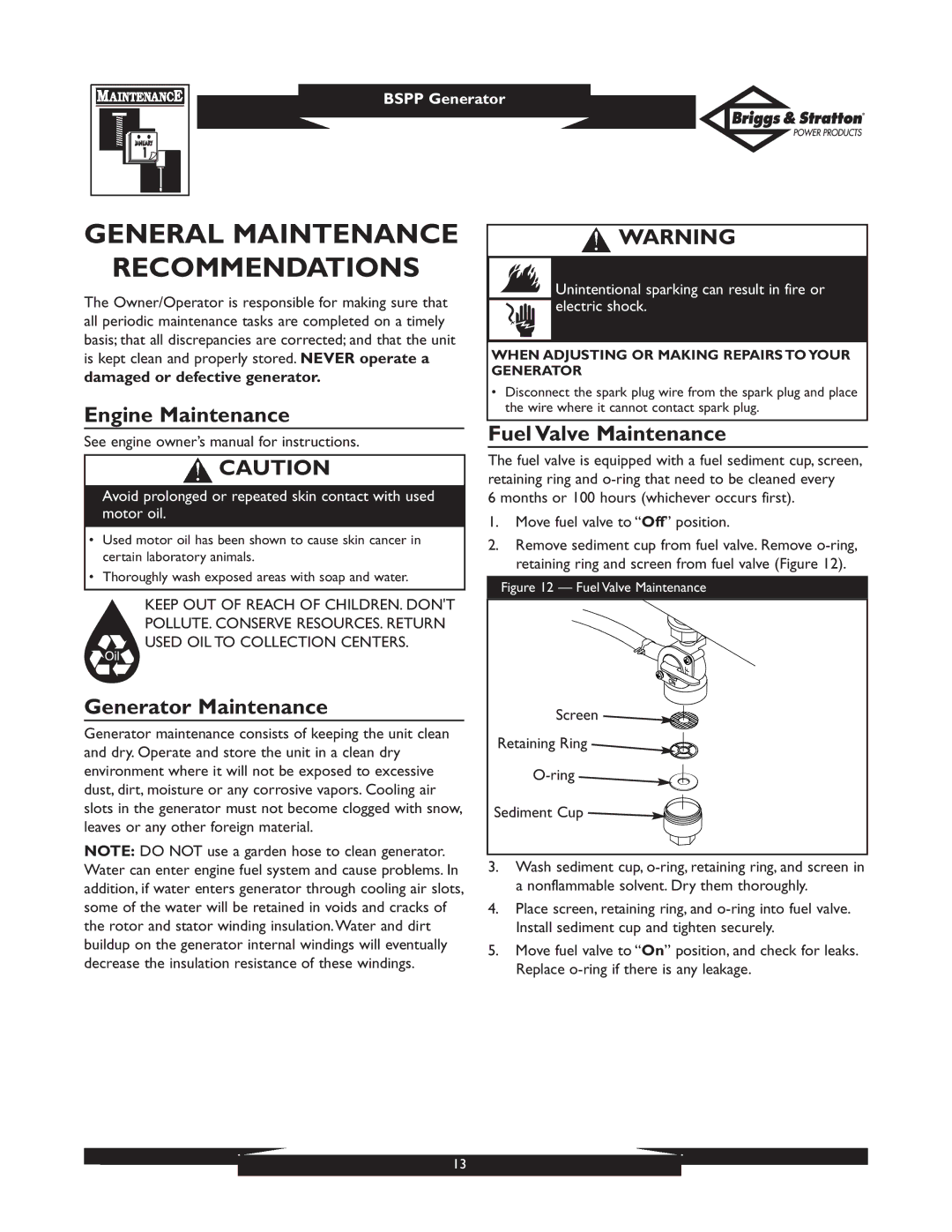

Fuel Valve Maintenance

The fuel valve is equipped with a fuel sediment cup, screen, retaining ring and

6 months or 100 hours (whichever occurs first).

1.Move fuel valve to “Off” position.

2.Remove sediment cup from fuel valve. Remove

Figure 12 — Fuel Valve Maintenance

KEEP OUT OF REACH OF CHILDREN. DON'T POLLUTE. CONSERVE RESOURCES. RETURN USED OIL TO COLLECTION CENTERS.

Generator Maintenance

Generator maintenance consists of keeping the unit clean and dry. Operate and store the unit in a clean dry environment where it will not be exposed to excessive dust, dirt, moisture or any corrosive vapors. Cooling air slots in the generator must not become clogged with snow, leaves or any other foreign material.

NOTE: DO NOT use a garden hose to clean generator. Water can enter engine fuel system and cause problems. In addition, if water enters generator through cooling air slots, some of the water will be retained in voids and cracks of the rotor and stator winding insulation.Water and dirt buildup on the generator internal windings will eventually decrease the insulation resistance of these windings.

Screen |

Retaining Ring |

Sediment Cup |

3.Wash sediment cup,

4.Place screen, retaining ring, and

5.Move fuel valve to “On” position, and check for leaks. Replace

13