315AAV

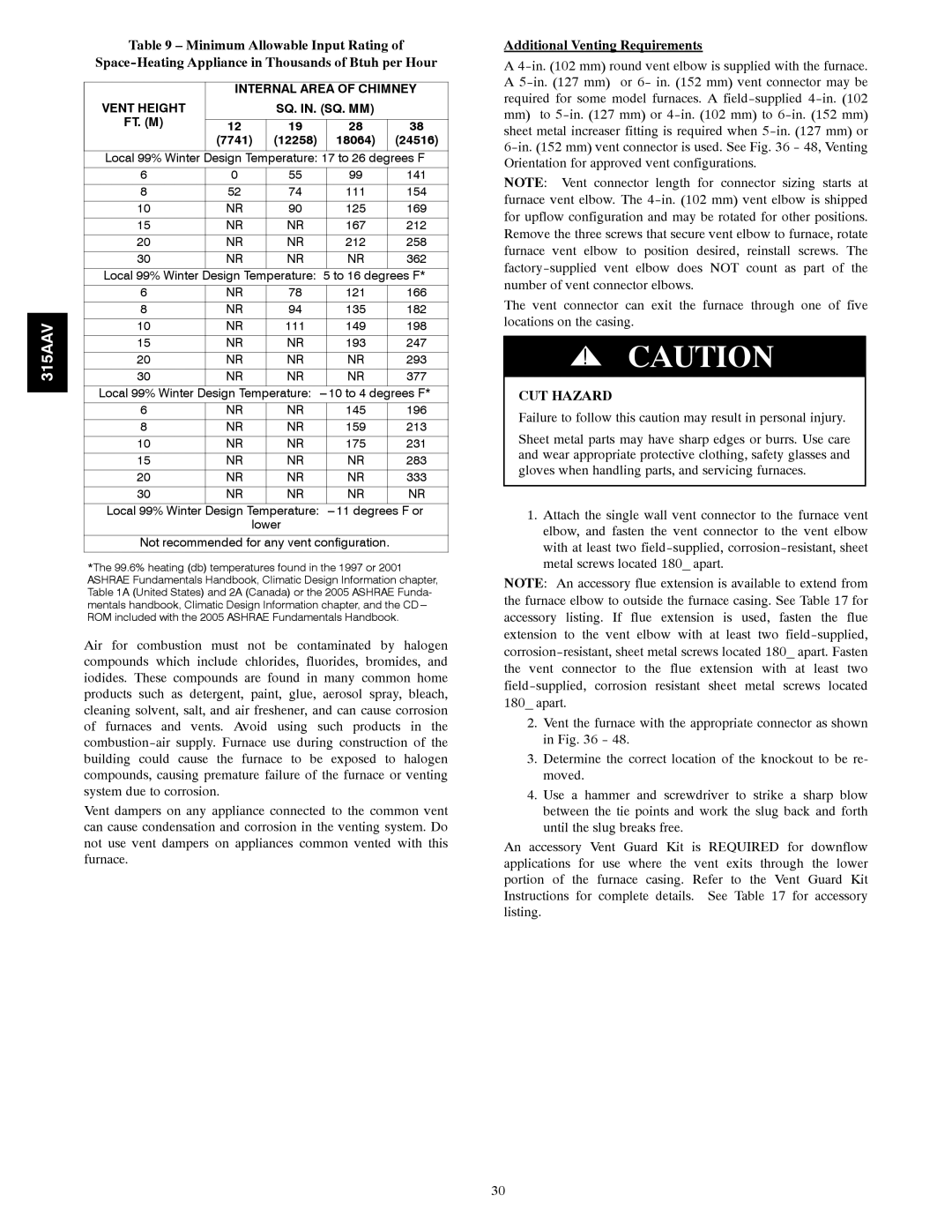

Table 9 – Minimum Allowable Input Rating of

| INTERNAL AREA OF CHIMNEY | |||

VENT HEIGHT |

| SQ. IN. (SQ. MM) |

| |

FT. (M) | 12 | 19 | 28 | 38 |

| (7741) | (12258) | 18064) | (24516) |

Local 99% Winter Design Temperature: 17 to 26 degrees F | ||||

6 | 0 | 55 | 99 | 141 |

8 | 52 | 74 | 111 | 154 |

10 | NR | 90 | 125 | 169 |

15 | NR | NR | 167 | 212 |

20 | NR | NR | 212 | 258 |

30 | NR | NR | NR | 362 |

Local 99% Winter Design Temperature: 5 to 16 degrees F* | ||||

6 | NR | 78 | 121 | 166 |

8 | NR | 94 | 135 | 182 |

10 | NR | 111 | 149 | 198 |

15 | NR | NR | 193 | 247 |

20 | NR | NR | NR | 293 |

30 | NR | NR | NR | 377 |

Local 99% Winter Design Temperature: | ||||

6 | NR | NR | 145 | 196 |

8 | NR | NR | 159 | 213 |

10 | NR | NR | 175 | 231 |

15 | NR | NR | NR | 283 |

20 | NR | NR | NR | 333 |

30 | NR | NR | NR | NR |

Local 99% Winter Design Temperature:

lower

Not recommended for any vent configuration.

*The 99.6% heating (db) temperatures found in the 1997 or 2001 ASHRAE Fundamentals Handbook, Climatic Design Information chapter, Table 1A (United States) and 2A (Canada) or the 2005 ASHRAE Funda- mentals handbook, Climatic Design Information chapter, and the CD

ROM included with the 2005 ASHRAE Fundamentals Handbook.

Air for combustion must not be contaminated by halogen compounds which include chlorides, fluorides, bromides, and iodides. These compounds are found in many common home products such as detergent, paint, glue, aerosol spray, bleach, cleaning solvent, salt, and air freshener, and can cause corrosion of furnaces and vents. Avoid using such products in the

Vent dampers on any appliance connected to the common vent can cause condensation and corrosion in the venting system. Do not use vent dampers on appliances common vented with this furnace.

Additional Venting Requirements

A

mm)to

NOTE: Vent connector length for connector sizing starts at furnace vent elbow. The

The vent connector can exit the furnace through one of five locations on the casing.

!CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear appropriate protective clothing, safety glasses and gloves when handling parts, and servicing furnaces.

1.Attach the single wall vent connector to the furnace vent elbow, and fasten the vent connector to the vent elbow with at least two

NOTE: An accessory flue extension is available to extend from the furnace elbow to outside the furnace casing. See Table 17 for accessory listing. If flue extension is used, fasten the flue extension to the vent elbow with at least two

2.Vent the furnace with the appropriate connector as shown in Fig. 36 - 48.

3.Determine the correct location of the knockout to be re- moved.

4.Use a hammer and screwdriver to strike a sharp blow between the tie points and work the slug back and forth until the slug breaks free.

An accessory Vent Guard Kit is REQUIRED for downflow applications for use where the vent exits through the lower portion of the furnace casing. Refer to the Vent Guard Kit Instructions for complete details. See Table 17 for accessory listing.

30