315AAV

Caution!! For the following applications, use the minimum vertical heights as specified below.

For all other applications, follow exclusively the National Fuel Gas Code.

FURNACE | VENT ORIENTATION | FURNACE INPUT | MIN. VENT | MIN. VERTICAL VENT | |

DIAMETER | HEIGHT | ||||

ORIENTATION |

| (BTUH/HR) | |||

| IN. (mm)* | FT. (M)** | |||

|

|

| |||

|

|

|

|

| |

Downflow | Vent elbow left, then up | 154,000 132,000 110,000 | 5 (127) | 12 (3.6) | |

Fig. 36 | |||||

|

|

|

| ||

|

|

|

|

| |

Horizontal Left | Vent elbow right, then up | 154,000 132,000 | 5 (127) | 7 (2.1) | |

Fig. 39 | |||||

|

|

|

| ||

|

|

|

|

| |

Horizontal Left | Vent Elbow up | 154,000 132,000 | 5 (127) | 7 (2.1) | |

Fig. 40 | |||||

|

|

|

| ||

Horizontal Left | Vent elbow right | 154,000 | 5 (127) | 7 (2.1) | |

Fig. 41 | |||||

|

|

|

| ||

|

|

|

|

| |

Downflow | Vent elbow up then left | 110,000 | 5 (127) | 10 (3.0) | |

Fig. 34 | |||||

|

|

|

| ||

Downflow | Vent elbow up, then right | 110,000 | 5 (127) | 10 (3.0) | |

Fig. 37 | |||||

|

|

|

| ||

NOTE: All vent configurations must also meet National Fuel Gas Code venting requirements NFGC. |

|

| |||

|

|

| |||

**Including 4 in. (102 mm) vent section(s) |

|

|

| ||

The horizontal portion of the venting system shall slope upwards not less than

Sidewall Venting

This furnace is not approved for direct sidewall horizontal venting.

Per section 12.4.3 of the NFPA 54/ANSI

Select the listed mechanical venter to match the Btuh input of the furnace being vented. Follow all manufacturer’s installation requirements for venting and termination included with the listed mechanical venter.

START-UP, ADJUSTMENT, AND SAFETY

CHECK

General

!WARNING

3.Gas supply pressure to the furnace must be greater than

4.Check all

5.Replace blower compartment door. Door must be in place to operate furnace.

6.Setup switch descriptions The variable speed furnace con- trol has DIP switches to select thermostat staging, blower off delay timings, air flow selection and other operational or service related functions. (See Fig. 26, 53 and Table 10.)

!CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear appropriate protective clothing, safety glasses and gloves when handling parts, and servicing furnaces.

FIRE HAZARD

Failure to follow this warning could result in personal injury, death or property damage.

This furnace is equipped with manual reset limit switches in the gas control area. The switches open and shut off power to the gas valve, if a flame rollout or overheating condition occurs in the gas control area. DO NOT bypass the switches. Correct problem before resetting the switches.

1. | Maintain |

| result in rapid flashing LED and no furnace operation. |

2. | Make thermostat wire connections at the |

| block on the furnace control. Failure to make proper con- |

| nections will result in improper operation. (See Fig. 25 - |

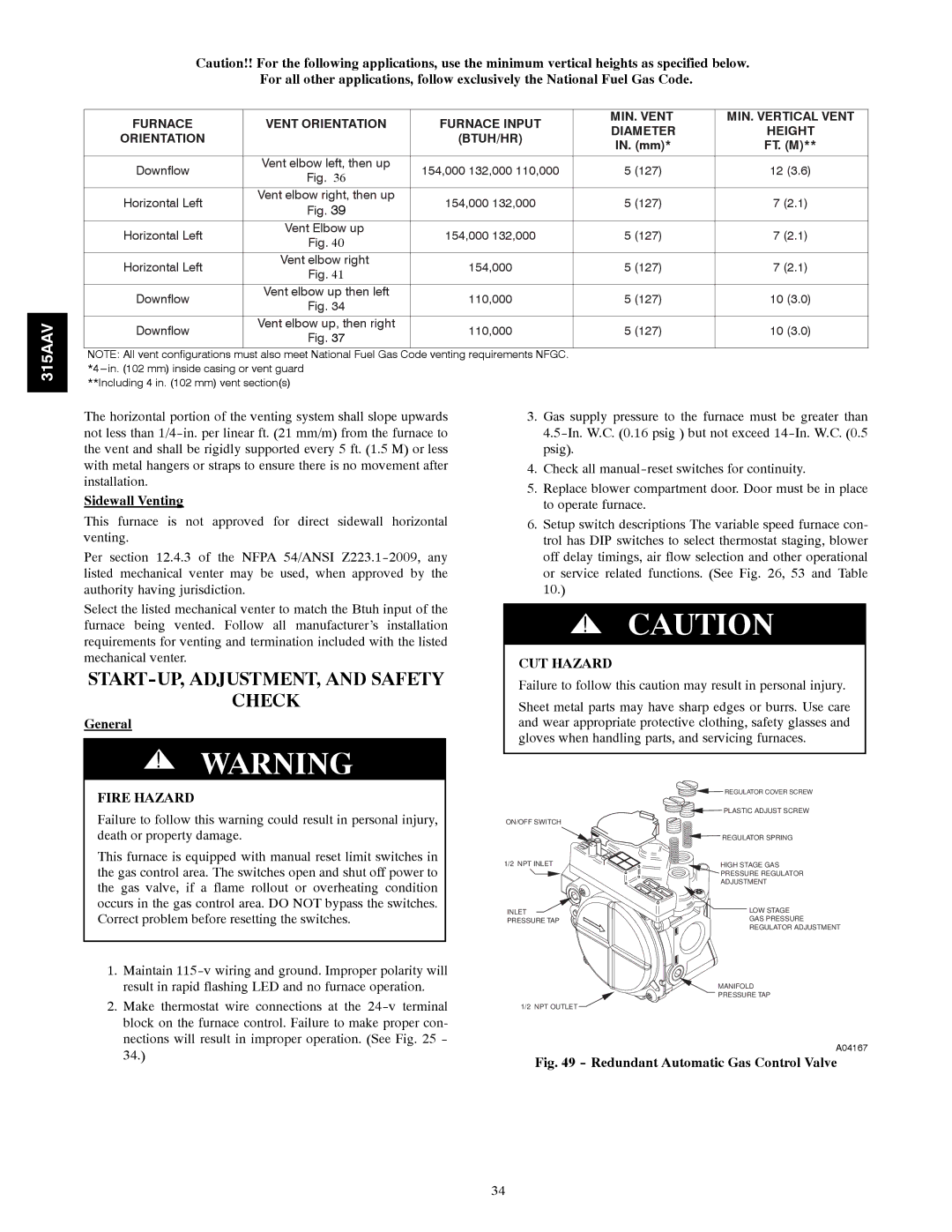

ON/OFF SWITCH

1/2˝ NPT INLET

INLET

PRESSURE TAP

1/2˝ NPT OUTLET![]()

![]()

![]() REGULATOR COVER SCREW

REGULATOR COVER SCREW

![]()

![]() PLASTIC ADJUST SCREW

PLASTIC ADJUST SCREW

![]()

![]()

![]() REGULATOR SPRING

REGULATOR SPRING

HIGH STAGE GAS

![]() PRESSURE REGULATOR

PRESSURE REGULATOR

ADJUSTMENT

LOW STAGE

GAS PRESSURE

REGULATOR ADJUSTMENT

MANIFOLD

PRESSURE TAP

34.) |

A04167

Fig. 49 - Redundant Automatic Gas Control Valve

34