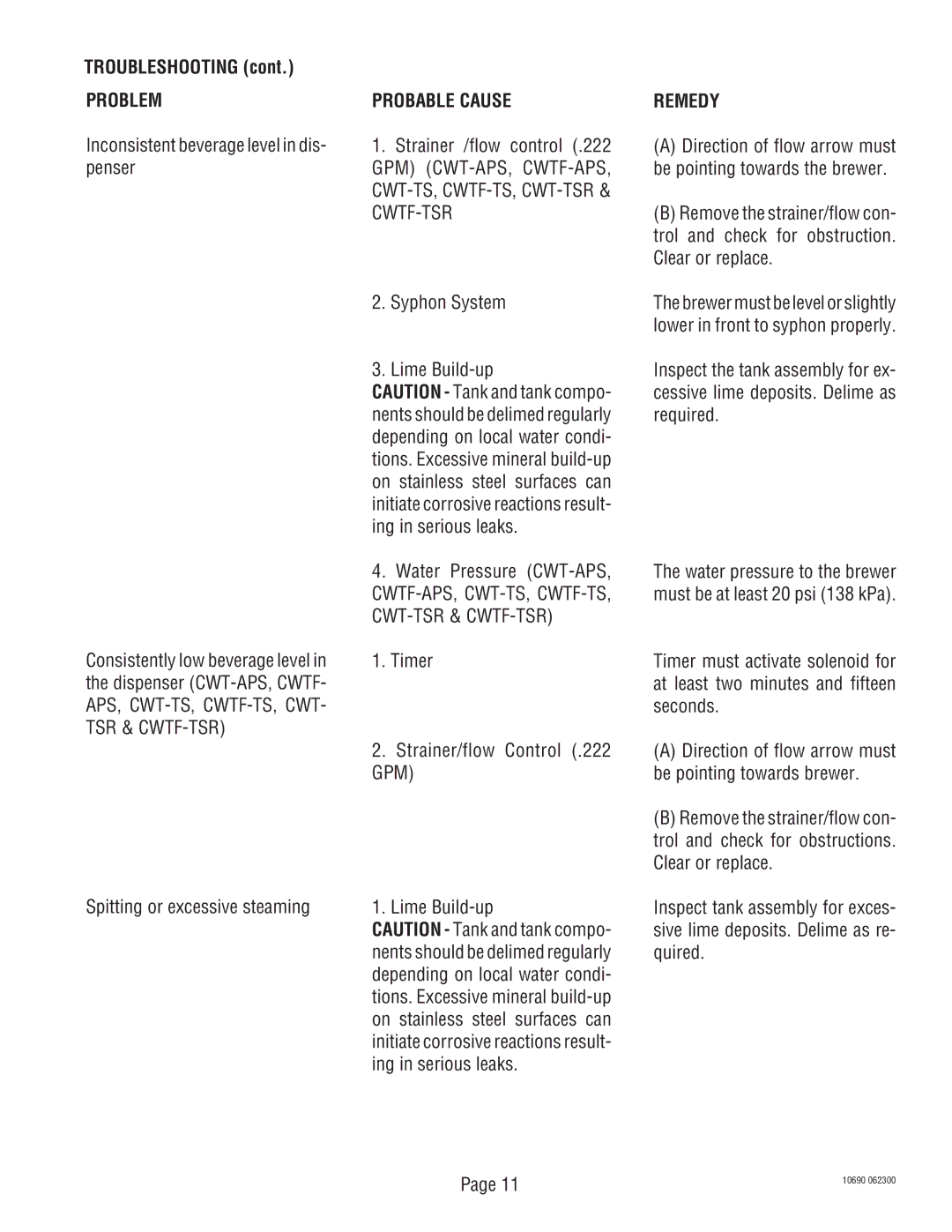

TROUBLESHOOTING (cont.)

PROBLEM

Inconsistent beverage level in dis- penser

Consistently low beverage level in the dispenser

Spitting or excessive steaming

PROBABLE CAUSE

1.Strainer /flow control (.222 GPM)

CWTF-TSR

2.Syphon System

3.Lime

CAUTION - Tank and tank compo- nents should be delimed regularly depending on local water condi- tions. Excessive mineral

4.Water Pressure

1.Timer

2.Strainer/flow Control (.222 GPM)

1. Lime

CAUTION - Tank and tank compo- nents should be delimed regularly depending on local water condi- tions. Excessive mineral

REMEDY

(A)Direction of flow arrow must be pointing towards the brewer.

(B)Remove the strainer/flow con- trol and check for obstruction. Clear or replace.

The brewer must be level or slightly lower in front to syphon properly.

Inspect the tank assembly for ex- cessive lime deposits. Delime as required.

The water pressure to the brewer must be at least 20 psi (138 kPa).

Timer must activate solenoid for at least two minutes and fifteen seconds.

(A)Direction of flow arrow must be pointing towards brewer.

(B)Remove the strainer/flow con- trol and check for obstructions. Clear or replace.

Inspect tank assembly for exces- sive lime deposits. Delime as re- quired.

Page 11 | 10690 062300 |

|