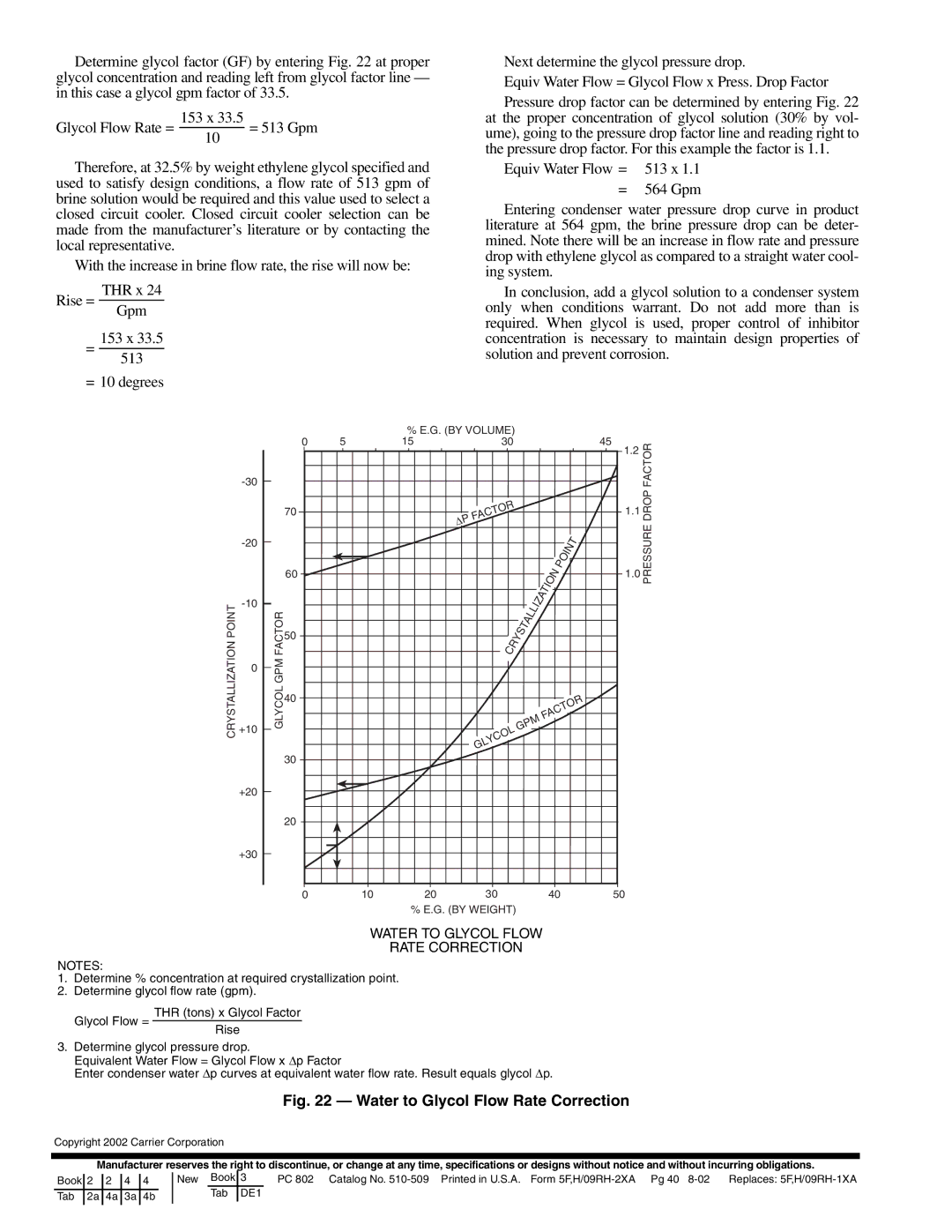

Determine glycol factor (GF) by entering Fig. 22 at proper glycol concentration and reading left from glycol factor line — in this case a glycol gpm factor of 33.5.

Glycol Flow Rate = 153 x 33.5 = 513 Gpm 10

Therefore, at 32.5% by weight ethylene glycol specified and used to satisfy design conditions, a flow rate of 513 gpm of brine solution would be required and this value used to select a closed circuit cooler. Closed circuit cooler selection can be made from the manufacturer’s literature or by contacting the local representative.

With the increase in brine flow rate, the rise will now be:

THR x 24

Rise =

Gpm

=153 x 33.5

513

=10 degrees

Next determine the glycol pressure drop.

Equiv Water Flow = Glycol Flow x Press. Drop Factor

Pressure drop factor can be determined by entering Fig. 22 at the proper concentration of glycol solution (30% by vol- ume), going to the pressure drop factor line and reading right to the pressure drop factor. For this example the factor is 1.1.

Equiv Water Flow = 513 x 1.1

=564 Gpm

Entering condenser water pressure drop curve in product literature at 564 gpm, the brine pressure drop can be deter- mined. Note there will be an increase in flow rate and pressure drop with ethylene glycol as compared to a straight water cool- ing system.

In conclusion, add a glycol solution to a condenser system only when conditions warrant. Do not add more than is required. When glycol is used, proper control of inhibitor concentration is necessary to maintain design properties of solution and prevent corrosion.

CRYSTALLIZATION POINT

0

+10

+20

+30

|

|

| % E.G. (BY VOLUME) |

|

|

|

| ||

| 0 | 5 | 15 |

| 30 |

|

| 45 | FACTORDROP |

| 70 |

|

|

| FACTOR |

|

| 1.1 | |

|

|

|

|

|

|

|

| 1.2 |

|

|

|

|

| ∆ |

|

|

|

|

|

|

|

|

| P |

|

|

|

| PRESSURE |

|

|

|

|

|

|

| POINT | 1.0 | |

| 60 |

|

|

| CRYSTALLIZATION |

| |||

|

|

|

|

|

|

|

| ||

FACTOR | 50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

GPM |

|

|

|

|

|

|

|

|

|

GLYCOL | 40 |

|

|

|

|

| FACTOR |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| GPM |

|

| |

|

|

|

|

| GLYCOL |

|

|

| |

|

|

|

|

|

|

|

|

| |

| 30 |

|

|

|

|

|

|

|

|

| 20 |

|

|

|

|

|

|

|

|

| 0 | 10 | 20 |

| 30 |

| 40 | 50 |

|

|

|

| % E.G. (BY WEIGHT) |

|

|

| |||

WATER TO GLYCOL FLOW

RATE CORRECTION

NOTES:

1.Determine % concentration at required crystallization point.

2.Determine glycol flow rate (gpm).

THR (tons) x Glycol Factor

Glycol Flow =

Rise

3.Determine glycol pressure drop.

Equivalent Water Flow = Glycol Flow x ∆p Factor

Enter condenser water ∆p curves at equivalent water flow rate. Result equals glycol ∆p.

Fig. 22 — Water to Glycol Flow Rate Correction

Copyright 2002 Carrier Corporation

| Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. | |||||||||

Book | 2 | 2 | 4 | 4 |

| New Book | 3 | PC 802 Catalog No. | Replaces: | |

|

|

|

|

|

|

| Tab | DE1 |

|

|

Tab | 2a | 4a | 3a | 4b |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|