Control Pressurestats — Dual pressurestats are furnished with all 5F,H compressors. They are often referred to as high- and

The high pressurestat has an operating range from 50 to 450 psig with a differential range from 170 to 235 psig (adj). The low pressurestat has an operating range from 20 in. Hg to 60 psig and a differential range from 60 to 90 psig (adj).

Pressurestat settings should be adjusted on the job to meet particular operating conditions for which the compressor(s) have been selected. Directions for setting these pressurestats are in the 5F,H Installation Instructions.

Permanently Unloaded Cylinders — Operation of an open- drive compressor with its cylinders permanently unloaded requires field modification. The 5F60, 5H40 and 5H60 com- pressors can operate with one cylinder unloaded; 5H80 and 5H120 compressors can operate with 2 cylinders unloaded. Compressors are modified by removing the suction valve and suction valve springs from the cylinder(s) shown in Fig. 4.

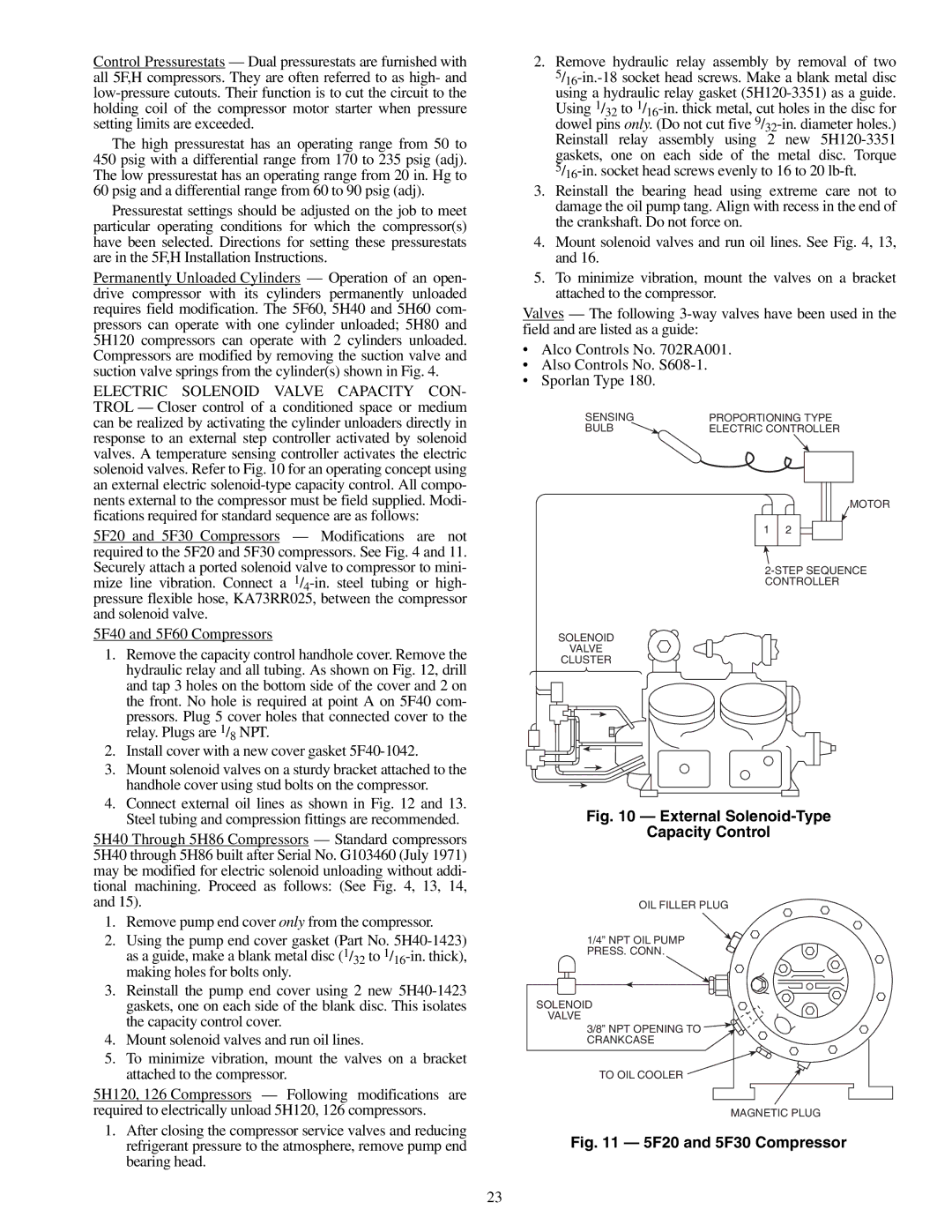

ELECTRIC SOLENOID VALVE CAPACITY CON- TROL — Closer control of a conditioned space or medium can be realized by activating the cylinder unloaders directly in response to an external step controller activated by solenoid valves. A temperature sensing controller activates the electric solenoid valves. Refer to Fig. 10 for an operating concept using an external electric

5F20 and 5F30 Compressors — Modifications are not required to the 5F20 and 5F30 compressors. See Fig. 4 and 11. Securely attach a ported solenoid valve to compressor to mini- mize line vibration. Connect a

5F40 and 5F60 Compressors

1.Remove the capacity control handhole cover. Remove the hydraulic relay and all tubing. As shown on Fig. 12, drill and tap 3 holes on the bottom side of the cover and 2 on the front. No hole is required at point A on 5F40 com-

pressors. Plug 5 cover holes that connected cover to the relay. Plugs are 1/8 NPT.

2.Install cover with a new cover gasket

3.Mount solenoid valves on a sturdy bracket attached to the handhole cover using stud bolts on the compressor.

4.Connect external oil lines as shown in Fig. 12 and 13. Steel tubing and compression fittings are recommended.

5H40 Through 5H86 Compressors — Standard compressors 5H40 through 5H86 built after Serial No. G103460 (July 1971) may be modified for electric solenoid unloading without addi- tional machining. Proceed as follows: (See Fig. 4, 13, 14, and 15).

1.Remove pump end cover only from the compressor.

2.Using the pump end cover gasket (Part No.

as a guide, make a blank metal disc (1/32 to

3.Reinstall the pump end cover using 2 new

4.Mount solenoid valves and run oil lines.

5.To minimize vibration, mount the valves on a bracket attached to the compressor.

5H120, 126 Compressors — Following modifications are required to electrically unload 5H120, 126 compressors.

1.After closing the compressor service valves and reducing refrigerant pressure to the atmosphere, remove pump end bearing head.

2.Remove hydraulic relay assembly by removal of two

Using 1/32 to

3.Reinstall the bearing head using extreme care not to damage the oil pump tang. Align with recess in the end of the crankshaft. Do not force on.

4.Mount solenoid valves and run oil lines. See Fig. 4, 13, and 16.

5.To minimize vibration, mount the valves on a bracket attached to the compressor.

Valves — The following

•Alco Controls No. 702RA001.

•Also Controls No.

•Sporlan Type 180.

SENSING | PROPORTIONING TYPE |

BULB | ELECTRIC CONTROLLER |

MOTOR

1 2

SOLENOID

VALVE

CLUSTER

Fig. 10 — External Solenoid-Type

Capacity Control

OIL FILLER PLUG

1/4” NPT OIL PUMP PRESS. CONN.

SOLENOID

VALVE

3/8” NPT OPENING TO ![]()

![]()

CRANKCASE

TO OIL COOLER

MAGNETIC PLUG

Fig. 11 — 5F20 and 5F30 Compressor

23