Table 13 — Minimum Gpm Required for

COMPRESSOR | GPM |

5F | |

5H (4, 6 and 8 Cylinders) | 6 |

5H (12 Cylinders) | 8 |

SAFETY RELIEF VALVES — All 5H compressors are equipped with

Safety relief valves that relieve at a 400 psi pressure differ- ential are factory installed on the 5F60 compressor but are not available with smaller 5F compressors.

SUCTION STRAINERS — Each 5F,H compressor is equipped with one or 2 suction strainers located in the suction manifold. On new installations, felt filters should be used in suction strainers to trap foreign material left after installation. After 50 hours of use, these felt filters must be removed. See 5F,H Installation Instructions for further details.

OIL SAFETY SWITCH — An oil safety switch is provided as standard with all compressors except 5F20 and 5F30. This switch is optional equipment on 5F20 and 5F30 compressors. This switch will shut off the compressor before high oil temperatures or lack of oil causes loss of oil pressure which can result in compressor failure. As a safety feature, this switch must be reset manually after cutout.

OIL SEPARATORS — Oil separators in the hot gas discharge line are not recommended for general use. However, there are systems where protection afforded by a separator is desirable, notably systems employing flooded evaporators or refrigera- tion systems with long system piping. For a more complete discussion see Carrier’s System Design Manual.

CRANKCASE OIL HEATERS — Crankcase oil heaters are available for all 5F,H compressors. Heaters keep the crankcase warm during off cycles and thus minimize refrigerant absorp- tion in the oil. Crankcase heaters are recommended for CFC or HCFC refrigerant applications and are required for HFC refrig- erant applications with POE lubricants. Refer to the 5F,H Installation Instructions for installation and wiring.

INTERCONNECTION OF COMPRESSORS — All 5F,H compressors are furnished with removable handhole cover plates on each crankcase. When field interconnection is desired on 5F40 through 5H86 compressors, cover plates can be removed and replaced by special cover plates with tapped open- ings. These tapped cover plates have connections for both oil and gas equalizing lines. For interconnection of 5F20 and 5F30 compressors, use the opening for the oil sight glass (see 5F,H Installation Instructions). Cover plates for interconnection are standard equipment on 5F120 and 126 compressors.

Many refrigeration systems utilize oil management compo- nents such as an oil separator, oil reservoir and floats. The oil level control float an be installed in the sight glass connection in the 5F,H handhole cover plate.

VIBRATION ISOLATORS — A standard vibration isolation package is available for each 5F,H compressor. This consists of a standard

The use of vibration isolators is recommended for all com- pressor and condensing units because:

1.Transfer of vibration to structure is reduced when the units are installed on upper floors.

2.They limit drive shaft misalignment on installations where units are bolted to an uneven concrete floor.

Vibration isolators giving approximately

MUFFLERS — Four standard mufflers cover the entire model range of 5F,H compressors. It is recommended that these mufflers be installed when compressors are used with remotely located

Mufflers are not usually necessary with smaller 5F compressors and their use is recommended only when quiet operation is required.

Each piping package to convert 5H compressor units to condensing units includes a standard muffler of appropriate size.

Pressure drop through mufflers is about 1/2 psi at 40 F suction and 105 F discharge with following loadings: 5 tons with 5F20 muffler, 15 tons with 5F40 muffler, 35 tons with 5H40 muffler and 100 tons with 5H120 muffler.

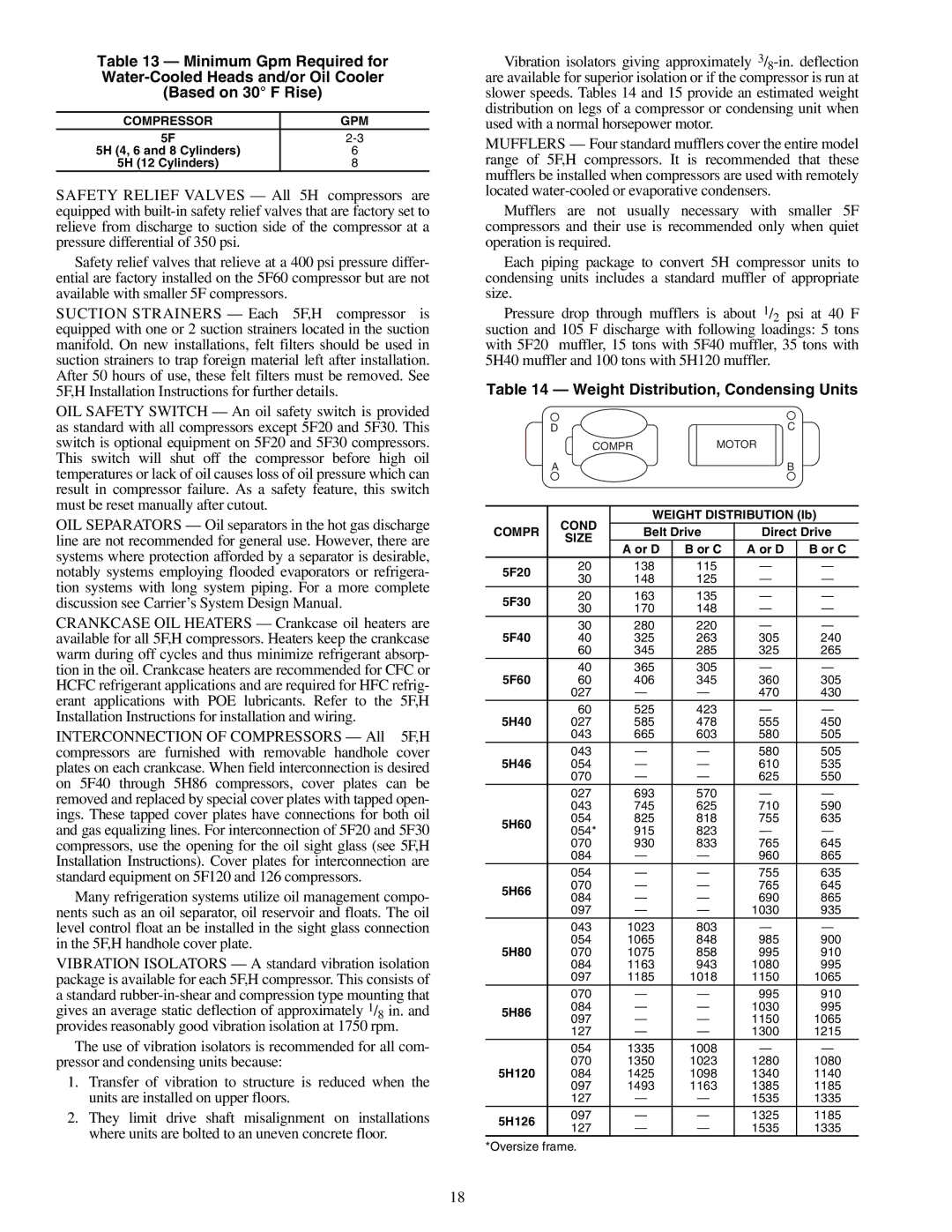

Table 14 — Weight Distribution, Condensing Units

D | C |

COMPR | MOTOR |

A | B |

| COND | WEIGHT DISTRIBUTION (lb) | ||||

COMPR | Belt Drive | Direct Drive | ||||

SIZE | ||||||

|

| A or D | B or C | A or D | B or C | |

5F20 | 20 | 138 | 115 | — | — | |

30 | 148 | 125 | — | — | ||

| ||||||

5F30 | 20 | 163 | 135 | — | — | |

30 | 170 | 148 | — | — | ||

| ||||||

5F40 | 30 | 280 | 220 | — | — | |

40 | 325 | 263 | 305 | 240 | ||

| 60 | 345 | 285 | 325 | 265 | |

5F60 | 40 | 365 | 305 | — | — | |

60 | 406 | 345 | 360 | 305 | ||

| 027 | — | — | 470 | 430 | |

5H40 | 60 | 525 | 423 | — | — | |

027 | 585 | 478 | 555 | 450 | ||

| 043 | 665 | 603 | 580 | 505 | |

5H46 | 043 | — | — | 580 | 505 | |

054 | — | — | 610 | 535 | ||

| 070 | — | — | 625 | 550 | |

| 027 | 693 | 570 | — | — | |

| 043 | 745 | 625 | 710 | 590 | |

5H60 | 054 | 825 | 818 | 755 | 635 | |

054* | 915 | 823 | — | — | ||

| ||||||

| 070 | 930 | 833 | 765 | 645 | |

| 084 | — | — | 960 | 865 | |

| 054 | — | — | 755 | 635 | |

5H66 | 070 | — | — | 765 | 645 | |

084 | — | — | 690 | 865 | ||

| ||||||

| 097 | — | — | 1030 | 935 | |

| 043 | 1023 | 803 | — | — | |

5H80 | 054 | 1065 | 848 | 985 | 900 | |

070 | 1075 | 858 | 995 | 910 | ||

| 084 | 1163 | 943 | 1080 | 995 | |

| 097 | 1185 | 1018 | 1150 | 1065 | |

| 070 | — | — | 995 | 910 | |

5H86 | 084 | — | — | 1030 | 995 | |

097 | — | — | 1150 | 1065 | ||

| ||||||

| 127 | — | — | 1300 | 1215 | |

| 054 | 1335 | 1008 | — | — | |

5H120 | 070 | 1350 | 1023 | 1280 | 1080 | |

084 | 1425 | 1098 | 1340 | 1140 | ||

| 097 | 1493 | 1163 | 1385 | 1185 | |

| 127 | — | — | 1535 | 1335 | |

5H126 | 097 | — | — | 1325 | 1185 | |

127 | — | — | 1535 | 1335 | ||

| ||||||

*Oversize frame.

18