NOTE: During this operation, maintain water circulation through the chiller cooler and condenser vessels to prevent tube

DISTILLING THE REFRIGERANT Ð Refrigerant vapor is transferred from the chiller cooler vessel or pumpout stor- age tank through the pumpout condenser, condensed to a liq- uid, and pumped to the chiller condenser vessel. During this operation, water circulation must be maintained in the pump- out condenser. Refrigerant impurities left in the chiller cooler vessel or storage tank are then drained off. This operation can take from 4 to 14 hours, depending on the type and amount of refrigerant being distilled.

The Pumpout and Refrigerant Transfer Procedures sec- tion gives

Pumpout and Refrigerant Transfer Procedures

ÐThree possibilities are available:

OIL RETURN LINE CONNECTION

VENT VALVE 8

PUMPOUT CONTROL BOX (WIRING BY CONTRACTOR)

1.If there are no isolation valves on the chiller, a complete pumpout system with a pumpout storage tank and pump- out unit is needed.

2.Whether or not isolation valves are available on the chiller, the refrigerant can be pumped to and isolated in a pump- out storage tank by using the pumpout unit.

3.If isolation valves are available on the chiller, the refrig- erant can be pumped to either the cooler vessel or the condenser vessel using the pumpout unit.

The following procedures describe how to transfer refrig- erant from one vessel to another and how to evacuate the chiller.

Do not mix refrigerants from chillers that use different compressor oils. Compressor damage can result. For ex- ample, the compressor oil in a 23XL chiller that uses

OPERATING THE PUMPOUT UNIT

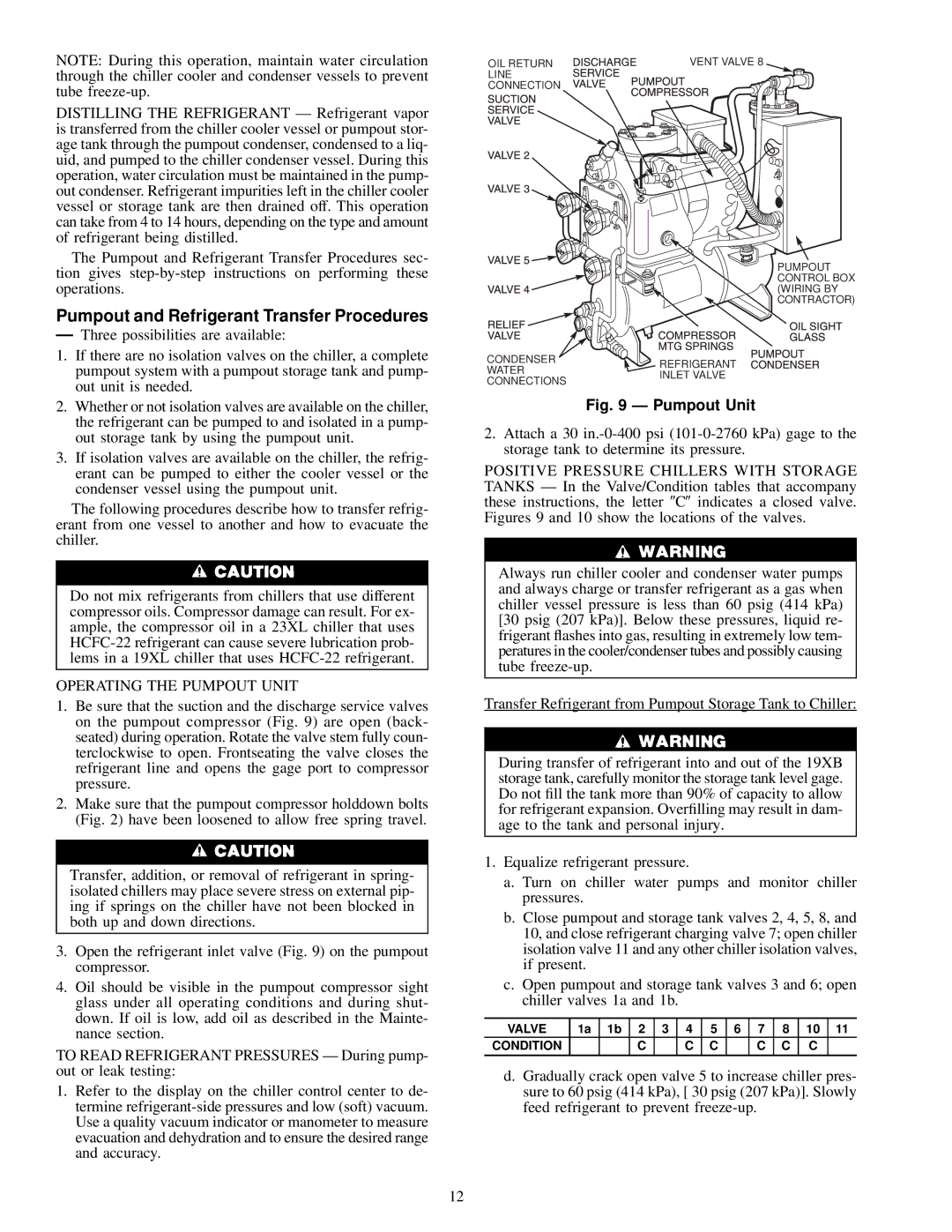

1.Be sure that the suction and the discharge service valves on the pumpout compressor (Fig. 9) are open (back- seated) during operation. Rotate the valve stem fully coun- terclockwise to open. Frontseating the valve closes the refrigerant line and opens the gage port to compressor pressure.

2.Make sure that the pumpout compressor holddown bolts (Fig. 2) have been loosened to allow free spring travel.

Transfer, addition, or removal of refrigerant in spring- isolated chillers may place severe stress on external pip- ing if springs on the chiller have not been blocked in both up and down directions.

3.Open the refrigerant inlet valve (Fig. 9) on the pumpout compressor.

4.Oil should be visible in the pumpout compressor sight glass under all operating conditions and during shut- down. If oil is low, add oil as described in the Mainte- nance section.

TO READ REFRIGERANT PRESSURES Ð During pump- out or leak testing:

1.Refer to the display on the chiller control center to de- termine

CONDENSER | REFRIGERANT | |

WATER | ||

INLET VALVE | ||

CONNECTIONS | ||

|

Fig. 9 Ð Pumpout Unit

2.Attach a 30

POSITIVE PRESSURE CHILLERS WITH STORAGE TANKS Ð In the Valve/Condition tables that accompany these instructions, the letter C indicates a closed valve. Figures 9 and 10 show the locations of the valves.

Always run chiller cooler and condenser water pumps and always charge or transfer refrigerant as a gas when chiller vessel pressure is less than 60 psig (414 kPa) [30 psig (207 kPa)]. Below these pressures, liquid re- frigerant ¯ashes into gas, resulting in extremely low tem- peratures in the cooler/condenser tubes and possibly causing tube

Transfer Refrigerant from Pumpout Storage Tank to Chiller:

During transfer of refrigerant into and out of the 19XB storage tank, carefully monitor the storage tank level gage. Do not ®ll the tank more than 90% of capacity to allow for refrigerant expansion. Over®lling may result in dam- age to the tank and personal injury.

1. Equalize refrigerant pressure.

a. Turn on chiller water pumps and monitor chiller pressures.

b. Close pumpout and storage tank valves 2, 4, 5, 8, and 10, and close refrigerant charging valve 7; open chiller isolation valve 11 and any other chiller isolation valves, if present.

c. Open pumpout and storage tank valves 3 and 6; open chiller valves 1a and 1b.

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 11 |

CONDITION |

|

| C |

| C | C |

| C | C | C |

|

|

|

|

|

|

|

|

|

|

|

|

|

d. Gradually crack open valve 5 to increase chiller pres- sure to 60 psig (414 kPa), [ 30 psig (207 kPa)]. Slowly feed refrigerant to prevent

12