PUMPOUT COMPRESSOR OIL CHARGE Ð Use oil con- forming to Carrier speci®cations for reciprocating compres- sor use. Oil requirements are listed in Table 6.

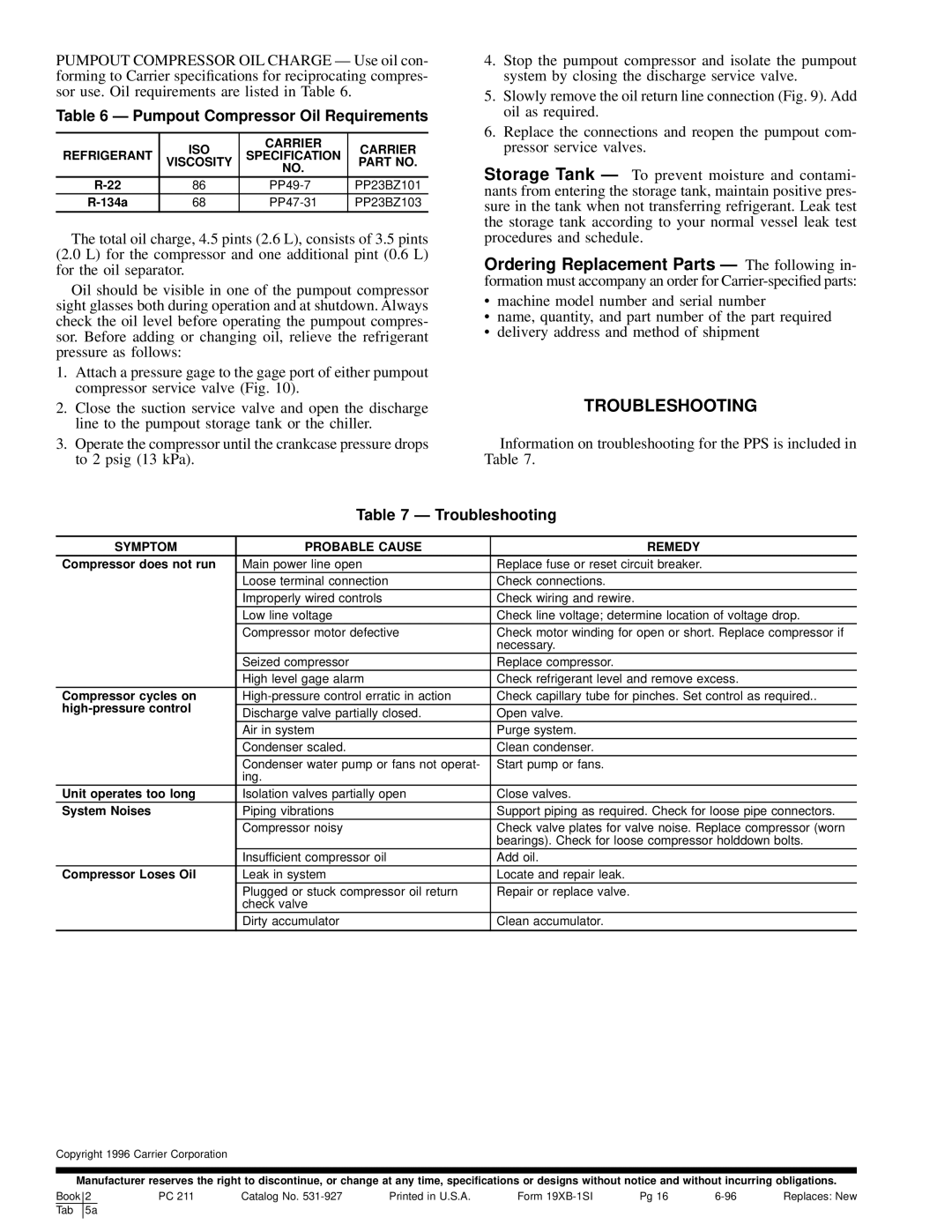

Table 6 Ð Pumpout Compressor Oil Requirements

| ISO | CARRIER | CARRIER | |

REFRIGERANT | SPECIFICATION | |||

VISCOSITY | PART NO. | |||

| NO. | |||

|

|

| ||

86 | PP23BZ101 | |||

68 | PP23BZ103 | |||

|

|

|

|

The total oil charge, 4.5 pints (2.6 L), consists of 3.5 pints (2.0 L) for the compressor and one additional pint (0.6 L) for the oil separator.

Oil should be visible in one of the pumpout compressor sight glasses both during operation and at shutdown. Always check the oil level before operating the pumpout compres- sor. Before adding or changing oil, relieve the refrigerant pressure as follows:

1.Attach a pressure gage to the gage port of either pumpout compressor service valve (Fig. 10).

2.Close the suction service valve and open the discharge line to the pumpout storage tank or the chiller.

3.Operate the compressor until the crankcase pressure drops to 2 psig (13 kPa).

4.Stop the pumpout compressor and isolate the pumpout system by closing the discharge service valve.

5.Slowly remove the oil return line connection (Fig. 9). Add oil as required.

6.Replace the connections and reopen the pumpout com- pressor service valves.

Storage Tank Ð To prevent moisture and contami- nants from entering the storage tank, maintain positive pres- sure in the tank when not transferring refrigerant. Leak test the storage tank according to your normal vessel leak test procedures and schedule.

Ordering Replacement Parts Ð The following in- formation must accompany an order for

·machine model number and serial number

·name, quantity, and part number of the part required

·delivery address and method of shipment

TROUBLESHOOTING

Information on troubleshooting for the PPS is included in Table 7.

Table 7 Ð Troubleshooting

SYMPTOM | PROBABLE CAUSE | REMEDY | |

Compressor does not run | Main power line open | Replace fuse or reset circuit breaker. | |

| Loose terminal connection | Check connections. | |

| Improperly wired controls | Check wiring and rewire. | |

| Low line voltage | Check line voltage; determine location of voltage drop. | |

| Compressor motor defective | Check motor winding for open or short. Replace compressor if | |

|

| necessary. | |

| Seized compressor | Replace compressor. | |

| High level gage alarm | Check refrigerant level and remove excess. | |

Compressor cycles on | Check capillary tube for pinches. Set control as required.. | ||

|

|

| |

Discharge valve partially closed. | Open valve. | ||

| |||

| Air in system | Purge system. | |

| Condenser scaled. | Clean condenser. | |

| Condenser water pump or fans not operat- | Start pump or fans. | |

| ing. |

| |

Unit operates too long | Isolation valves partially open | Close valves. | |

System Noises | Piping vibrations | Support piping as required. Check for loose pipe connectors. | |

| Compressor noisy | Check valve plates for valve noise. Replace compressor (worn | |

|

| bearings). Check for loose compressor holddown bolts. | |

| Insufficient compressor oil | Add oil. | |

Compressor Loses Oil | Leak in system | Locate and repair leak. | |

| Plugged or stuck compressor oil return | Repair or replace valve. | |

| check valve |

| |

| Dirty accumulator | Clean accumulator. | |

|

|

|

Copyright 1996 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, speci®cations or designs without notice and without incurring obligations.

Book | 2 |

| PC 211 | Catalog No. | Printed in U.S.A. | Form | Pg 16 | Replaces: New | |

Tab | 5a |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|