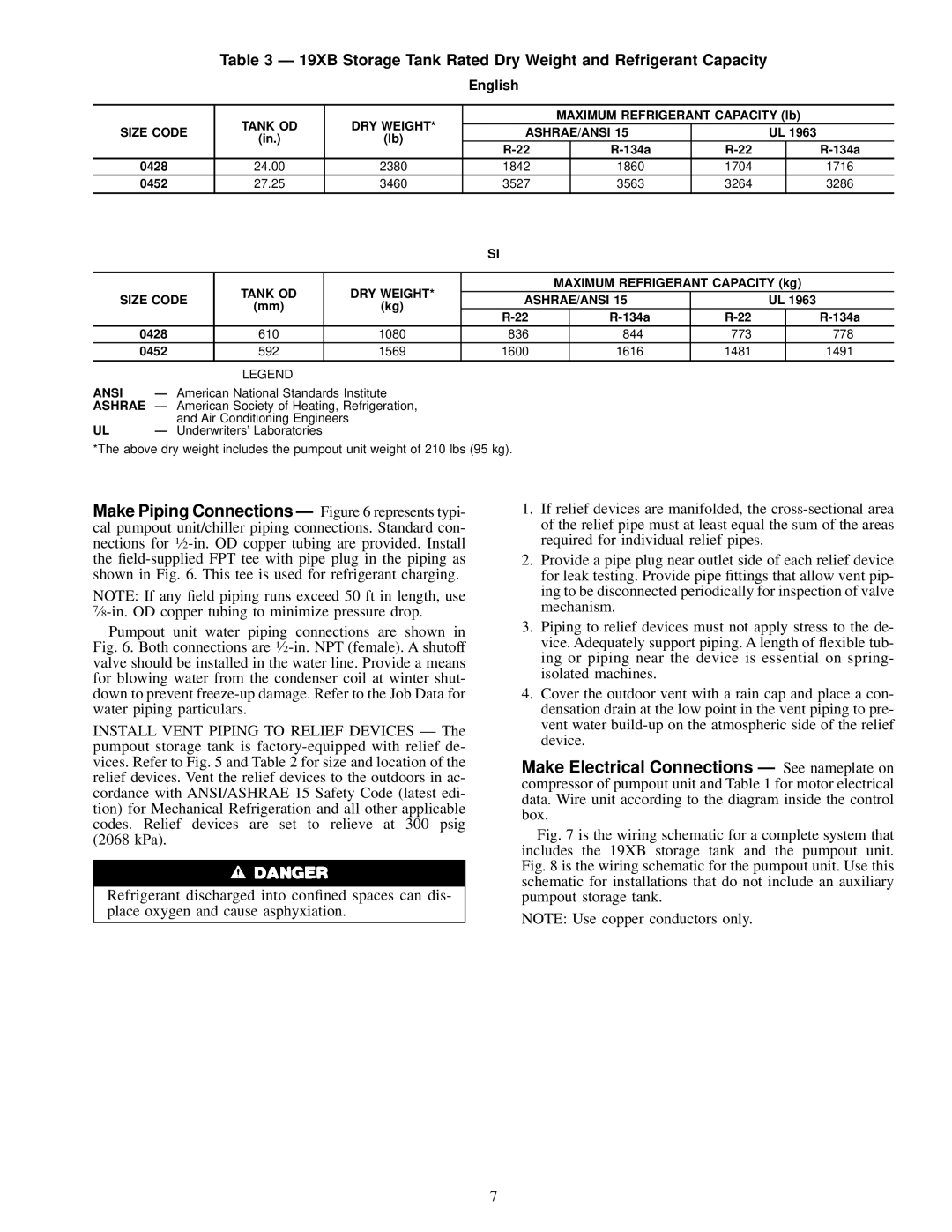

Table 3 Ð 19XB Storage Tank Rated Dry Weight and Refrigerant Capacity

English

|

|

| TANK OD |

| DRY WEIGHT* |

| MAXIMUM REFRIGERANT CAPACITY (lb) |

| |||

SIZE CODE |

| ASHRAE/ANSI 15 | UL 1963 |

| |||||||

(in.) |

| (lb) |

| ||||||||

|

|

|

|

|

|

|

| ||||

| 0428 |

| 24.00 |

| 2380 | 1842 |

| 1860 | 1704 |

| 1716 |

| 0452 |

| 27.25 |

| 3460 | 3527 |

| 3563 | 3264 |

| 3286 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TANK OD |

| DRY WEIGHT* |

| MAXIMUM REFRIGERANT CAPACITY (kg) |

| |||

SIZE CODE |

| ASHRAE/ANSI 15 | UL 1963 |

| |||||||

(mm) |

| (kg) |

| ||||||||

|

|

|

|

|

|

|

| ||||

| 0428 |

| 610 |

| 1080 | 836 |

| 844 | 773 |

| 778 |

| 0452 |

| 592 |

| 1569 | 1600 |

| 1616 | 1481 |

| 1491 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LEGEND |

|

|

|

|

|

|

| |

ANSI | Ð | American National Standards Institute |

|

|

|

|

|

| |||

ASHRAE Ð American Society of Heating, Refrigeration, |

|

|

|

|

|

| |||||

|

| and Air Conditioning Engineers |

|

|

|

|

|

|

| ||

UL | Ð Underwriters' Laboratories |

|

|

|

|

|

|

| |||

*The above dry weight includes the pumpout unit weight of 210 lbs (95 kg).

Make Piping Connections Ð Figure 6 represents typi- cal pumpout unit/chiller piping connections. Standard con- nections for

NOTE: If any ®eld piping runs exceed 50 ft in length, use

Pumpout unit water piping connections are shown in Fig. 6. Both connections are

INSTALL VENT PIPING TO RELIEF DEVICES Ð The pumpout storage tank is

Refrigerant discharged into con®ned spaces can dis- place oxygen and cause asphyxiation.

1.If relief devices are manifolded, the

2.Provide a pipe plug near outlet side of each relief device for leak testing. Provide pipe ®ttings that allow vent pip- ing to be disconnected periodically for inspection of valve mechanism.

3.Piping to relief devices must not apply stress to the de- vice. Adequately support piping. A length of ¯exible tub- ing or piping near the device is essential on spring- isolated machines.

4.Cover the outdoor vent with a rain cap and place a con- densation drain at the low point in the vent piping to pre- vent water

Make Electrical Connections Ð See nameplate on compressor of pumpout unit and Table 1 for motor electrical data. Wire unit according to the diagram inside the control box.

Fig. 7 is the wiring schematic for a complete system that includes the 19XB storage tank and the pumpout unit. Fig. 8 is the wiring schematic for the pumpout unit. Use this schematic for installations that do not include an auxiliary pumpout storage tank.

NOTE: Use copper conductors only.

7