d. Close valve 1a.

e. Turn off pumpout compressor. f. Close valves 1b, 3, and 4.

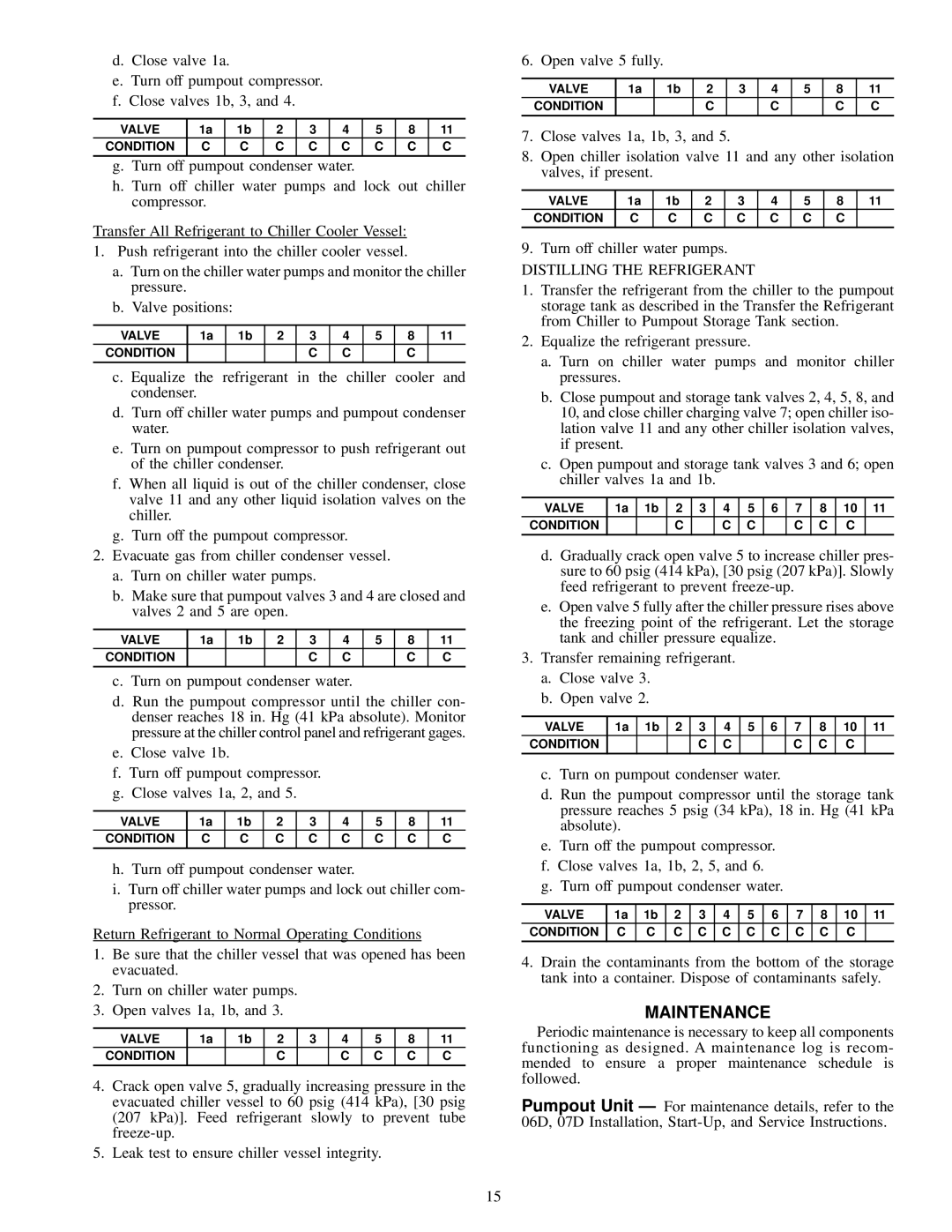

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 8 | 11 |

CONDITION | C | C | C | C | C | C | C | C |

|

|

|

|

|

|

|

|

|

g. Turn off pumpout condenser water.

h. Turn off chiller water pumps and lock out chiller compressor.

Transfer All Refrigerant to Chiller Cooler Vessel: 1. Push refrigerant into the chiller cooler vessel.

a. Turn on the chiller water pumps and monitor the chiller pressure.

b. Valve positions:

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 8 | 11 |

CONDITION |

|

|

| C | C |

| C |

|

|

|

|

|

|

|

|

|

|

c. Equalize the refrigerant in the chiller cooler and condenser.

d. Turn off chiller water pumps and pumpout condenser water.

e. Turn on pumpout compressor to push refrigerant out of the chiller condenser.

f. When all liquid is out of the chiller condenser, close valve 11 and any other liquid isolation valves on the chiller.

g. Turn off the pumpout compressor.

2. Evacuate gas from chiller condenser vessel. a. Turn on chiller water pumps.

b. Make sure that pumpout valves 3 and 4 are closed and valves 2 and 5 are open.

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 8 | 11 |

CONDITION |

|

|

| C | C |

| C | C |

|

|

|

|

|

|

|

|

|

c. Turn on pumpout condenser water.

d. Run the pumpout compressor until the chiller con- denser reaches 18 in. Hg (41 kPa absolute). Monitor pressure at the chiller control panel and refrigerant gages.

e. Close valve 1b.

f. Turn off pumpout compressor. g. Close valves 1a, 2, and 5.

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 8 | 11 |

CONDITION | C | C | C | C | C | C | C | C |

h. Turn off pumpout condenser water.

i. Turn off chiller water pumps and lock out chiller com- pressor.

Return Refrigerant to Normal Operating Conditions

1. | Be sure that the chiller vessel that was opened has been | ||||||||

| evacuated. |

|

|

|

|

|

|

|

|

2. | Turn on chiller water pumps. |

|

|

|

|

| |||

3. | Open valves 1a, 1b, and 3. |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 8 | 11 |

| CONDITION |

|

| C |

| C | C | C | C |

|

|

|

|

|

|

|

|

|

|

4. | Crack open valve 5, gradually increasing pressure in the | ||||||||

| evacuated chiller vessel to 60 psig (414 kPa), [30 psig | ||||||||

| (207 kPa)]. Feed refrigerant slowly to prevent tube | ||||||||

|

|

|

|

|

|

|

|

|

|

5. | Leak test to ensure chiller vessel integrity. |

|

| ||||||

6. Open valve 5 fully.

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 8 | 11 |

CONDITION |

|

| C |

| C |

| C | C |

7. Close valves 1a, 1b, 3, and 5.

8. Open chiller isolation valve 11 and any other isolation valves, if present.

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 8 | 11 |

CONDITION | C | C | C | C | C | C | C |

|

9. Turn off chiller water pumps.

DISTILLING THE REFRIGERANT

1. Transfer the refrigerant from the chiller to the pumpout storage tank as described in the Transfer the Refrigerant from Chiller to Pumpout Storage Tank section.

2. Equalize the refrigerant pressure.

a. Turn on chiller water pumps and monitor chiller pressures.

b. Close pumpout and storage tank valves 2, 4, 5, 8, and 10, and close chiller charging valve 7; open chiller iso- lation valve 11 and any other chiller isolation valves, if present.

c. Open pumpout and storage tank valves 3 and 6; open chiller valves 1a and 1b.

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 11 |

CONDITION |

|

| C |

| C | C |

| C | C | C |

|

|

|

|

|

|

|

|

|

|

|

|

|

d. Gradually crack open valve 5 to increase chiller pres- sure to 60 psig (414 kPa), [30 psig (207 kPa)]. Slowly feed refrigerant to prevent

e. Open valve 5 fully after the chiller pressure rises above the freezing point of the refrigerant. Let the storage tank and chiller pressure equalize.

3. Transfer remaining refrigerant. a. Close valve 3.

b. Open valve 2.

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 11 |

CONDITION |

|

|

| C | C |

|

| C | C | C |

|

c. Turn on pumpout condenser water.

d. Run the pumpout compressor until the storage tank pressure reaches 5 psig (34 kPa), 18 in. Hg (41 kPa absolute).

e. Turn off the pumpout compressor. f. Close valves 1a, 1b, 2, 5, and 6. g. Turn off pumpout condenser water.

VALVE | 1a | 1b | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 11 |

CONDITION | C | C | C | C | C | C | C | C | C | C |

|

4. Drain the contaminants from the bottom of the storage tank into a container. Dispose of contaminants safely.

MAINTENANCE

Periodic maintenance is necessary to keep all components functioning as designed. A maintenance log is recom- mended to ensure a proper maintenance schedule is followed.

Pumpout Unit Ð For maintenance details, refer to the 06D, 07D Installation,

15