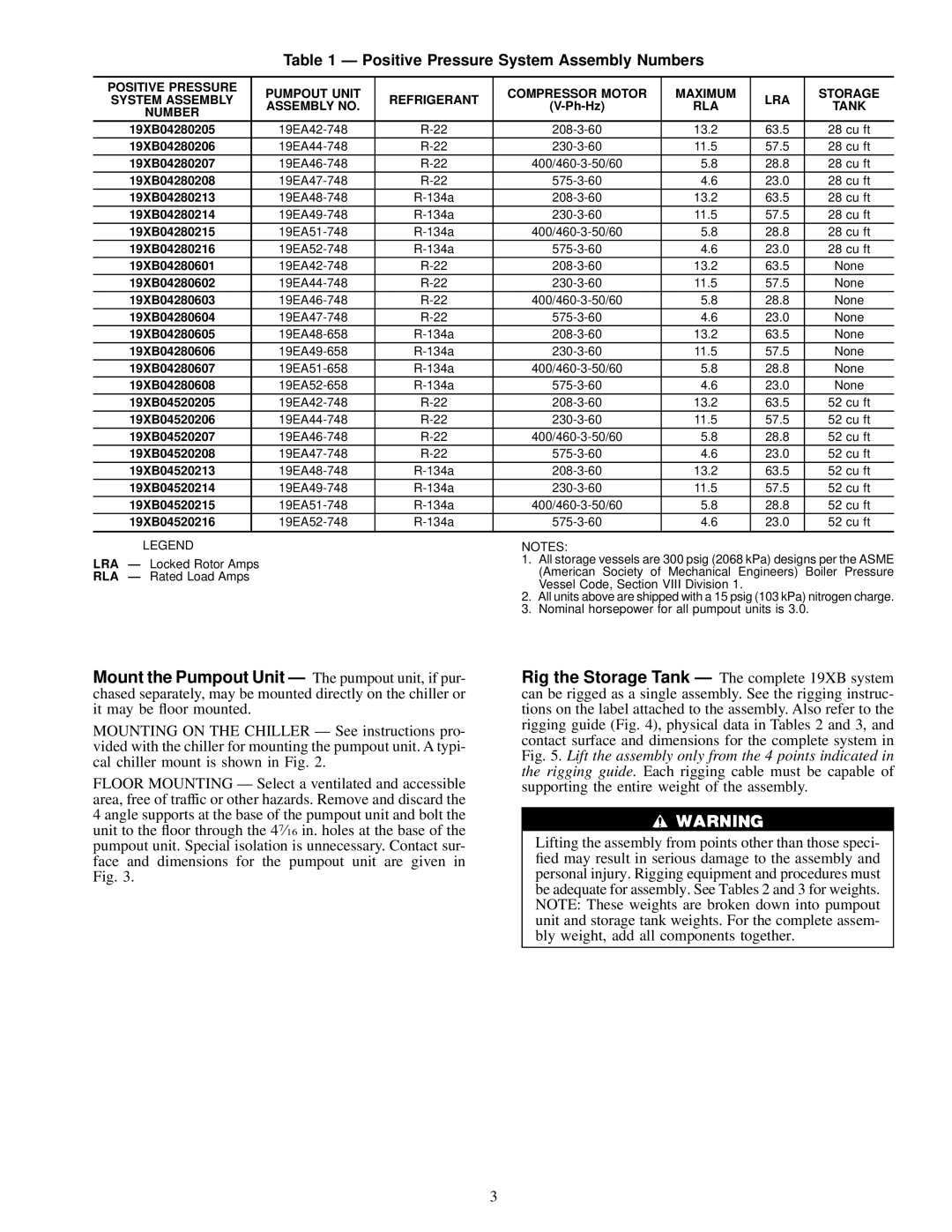

Table 1 Ð Positive Pressure System Assembly Numbers

POSITIVE PRESSURE | PUMPOUT UNIT |

| COMPRESSOR MOTOR | MAXIMUM |

| STORAGE | |

SYSTEM ASSEMBLY | REFRIGERANT | LRA | |||||

ASSEMBLY NO. | RLA | TANK | |||||

NUMBER |

|

| |||||

|

|

|

|

|

| ||

19XB04280205 | 13.2 | 63.5 | 28 cu ft | ||||

19XB04280206 | 11.5 | 57.5 | 28 cu ft | ||||

19XB04280207 | 5.8 | 28.8 | 28 cu ft | ||||

19XB04280208 | 4.6 | 23.0 | 28 cu ft | ||||

19XB04280213 | 13.2 | 63.5 | 28 cu ft | ||||

19XB04280214 | 11.5 | 57.5 | 28 cu ft | ||||

19XB04280215 | 5.8 | 28.8 | 28 cu ft | ||||

19XB04280216 | 4.6 | 23.0 | 28 cu ft | ||||

19XB04280601 | 13.2 | 63.5 | None | ||||

19XB04280602 | 11.5 | 57.5 | None | ||||

19XB04280603 | 5.8 | 28.8 | None | ||||

19XB04280604 | 4.6 | 23.0 | None | ||||

19XB04280605 | 13.2 | 63.5 | None | ||||

19XB04280606 | 11.5 | 57.5 | None | ||||

19XB04280607 | 5.8 | 28.8 | None | ||||

19XB04280608 | 4.6 | 23.0 | None | ||||

19XB04520205 | 13.2 | 63.5 | 52 cu ft | ||||

19XB04520206 | 11.5 | 57.5 | 52 cu ft | ||||

19XB04520207 | 5.8 | 28.8 | 52 cu ft | ||||

19XB04520208 | 4.6 | 23.0 | 52 cu ft | ||||

19XB04520213 | 13.2 | 63.5 | 52 cu ft | ||||

19XB04520214 | 11.5 | 57.5 | 52 cu ft | ||||

19XB04520215 | 5.8 | 28.8 | 52 cu ft | ||||

19XB04520216 | 4.6 | 23.0 | 52 cu ft | ||||

|

|

|

|

|

|

|

LEGEND

LRA Ð Locked Rotor Amps RLA Ð Rated Load Amps

NOTES:

1.All storage vessels are 300 psig (2068 kPa) designs per the ASME (American Society of Mechanical Engineers) Boiler Pressure Vessel Code, Section VIII Division 1.

2.All units above are shipped with a 15 psig (103 kPa) nitrogen charge.

3.Nominal horsepower for all pumpout units is 3.0.

Mount the Pumpout Unit Ð The pumpout unit, if pur- chased separately, may be mounted directly on the chiller or it may be ¯oor mounted.

MOUNTING ON THE CHILLER Ð See instructions pro- vided with the chiller for mounting the pumpout unit. A typi- cal chiller mount is shown in Fig. 2.

FLOOR MOUNTING Ð Select a ventilated and accessible area, free of traffic or other hazards. Remove and discard the 4 angle supports at the base of the pumpout unit and bolt the unit to the ¯oor through the 47¤16 in. holes at the base of the pumpout unit. Special isolation is unnecessary. Contact sur- face and dimensions for the pumpout unit are given in Fig. 3.

Rig the Storage Tank Ð The complete 19XB system can be rigged as a single assembly. See the rigging instruc- tions on the label attached to the assembly. Also refer to the rigging guide (Fig. 4), physical data in Tables 2 and 3, and contact surface and dimensions for the complete system in Fig. 5. Lift the assembly only from the 4 points indicated in the rigging guide. Each rigging cable must be capable of supporting the entire weight of the assembly.

Lifting the assembly from points other than those speci- ®ed may result in serious damage to the assembly and personal injury. Rigging equipment and procedures must be adequate for assembly. See Tables 2 and 3 for weights. NOTE: These weights are broken down into pumpout unit and storage tank weights. For the complete assem- bly weight, add all components together.

3