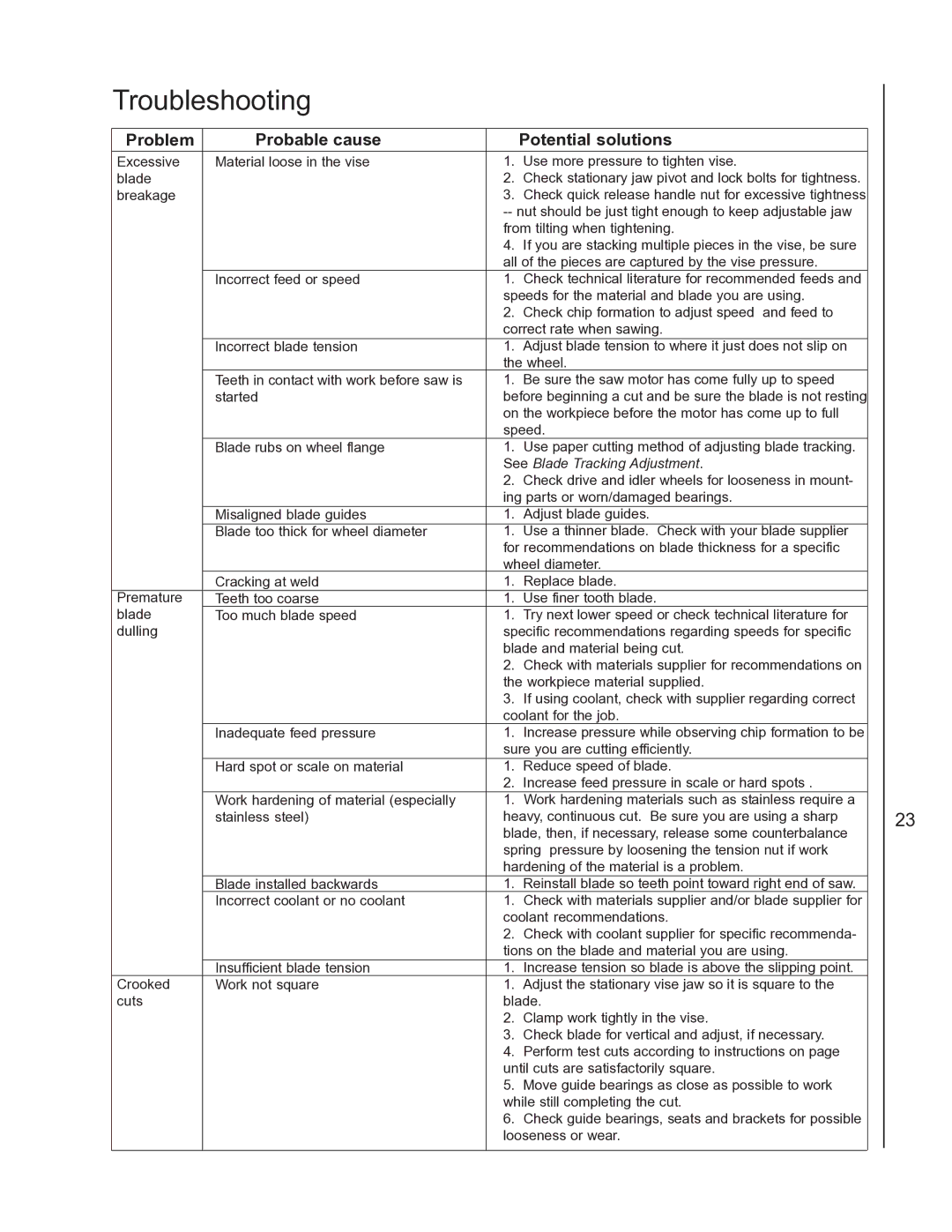

Troubleshooting

Problem | Probable cause |

| Potential solutions |

Excessive | Material loose in the vise | 1. | Use more pressure to tighten vise. |

blade |

| 2. | Check stationary jaw pivot and lock bolts for tightness. |

breakage |

| 3. | Check quick release handle nut for excessive tightness |

|

| ||

|

| from tilting when tightening. | |

|

| 4. | If you are stacking multiple pieces in the vise, be sure |

|

| all of the pieces are captured by the vise pressure. | |

| Incorrect feed or speed | 1. | Check technical literature for recommended feeds and |

|

| speeds for the material and blade you are using. | |

|

| 2. | Check chip formation to adjust speed and feed to |

|

| correct rate when sawing. | |

| Incorrect blade tension | 1. | Adjust blade tension to where it just does not slip on |

|

| the wheel. | |

| Teeth in contact with work before saw is | 1. | Be sure the saw motor has come fully up to speed |

| started | before beginning a cut and be sure the blade is not resting | |

|

| on the workpiece before the motor has come up to full | |

|

| speed. | |

| Blade rubs on wheel flange | 1. | Use paper cutting method of adjusting blade tracking. |

|

| See Blade Tracking Adjustment. | |

|

| 2. | Check drive and idler wheels for looseness in mount- |

|

| ing parts or worn/damaged bearings. | |

| Misaligned blade guides | 1. | Adjust blade guides. |

| Blade too thick for wheel diameter | 1. | Use a thinner blade. Check with your blade supplier |

|

| for recommendations on blade thickness for a specific | |

|

| wheel diameter. | |

| Cracking at weld | 1. | Replace blade. |

Premature | Teeth too coarse | 1. | Use finer tooth blade. |

blade | Too much blade speed | 1. | Try next lower speed or check technical literature for |

dulling |

| specific recommendations regarding speeds for specific | |

|

| blade and material being cut. | |

|

| 2. | Check with materials supplier for recommendations on |

|

| the workpiece material supplied. | |

|

| 3. | If using coolant, check with supplier regarding correct |

|

| coolant for the job. | |

| Inadequate feed pressure | 1. | Increase pressure while observing chip formation to be |

|

| sure you are cutting efficiently. | |

| Hard spot or scale on material | 1. | Reduce speed of blade. |

|

| 2. | Increase feed pressure in scale or hard spots . |

| Work hardening of material (especially | 1. | Work hardening materials such as stainless require a |

| stainless steel) | heavy, continuous cut. Be sure you are using a sharp | |

|

| blade, then, if necessary, release some counterbalance | |

|

| spring pressure by loosening the tension nut if work | |

|

| hardening of the material is a problem. | |

| Blade installed backwards | 1. | Reinstall blade so teeth point toward right end of saw. |

| Incorrect coolant or no coolant | 1. | Check with materials supplier and/or blade supplier for |

|

| coolant recommendations. | |

|

| 2. | Check with coolant supplier for specific recommenda- |

|

| tions on the blade and material you are using. | |

| Insufficient blade tension | 1. | Increase tension so blade is above the slipping point. |

Crooked | Work not square | 1. | Adjust the stationary vise jaw so it is square to the |

cuts |

| blade. | |

|

| 2. | Clamp work tightly in the vise. |

|

| 3. | Check blade for vertical and adjust, if necessary. |

|

| 4. | Perform test cuts according to instructions on page |

|

| until cuts are satisfactorily square. | |

|

| 5. | Move guide bearings as close as possible to work |

|

| while still completing the cut. | |

|

| 6. | Check guide bearings, seats and brackets for possible |

|

| looseness or wear. | |

|

|

|

|

23