24

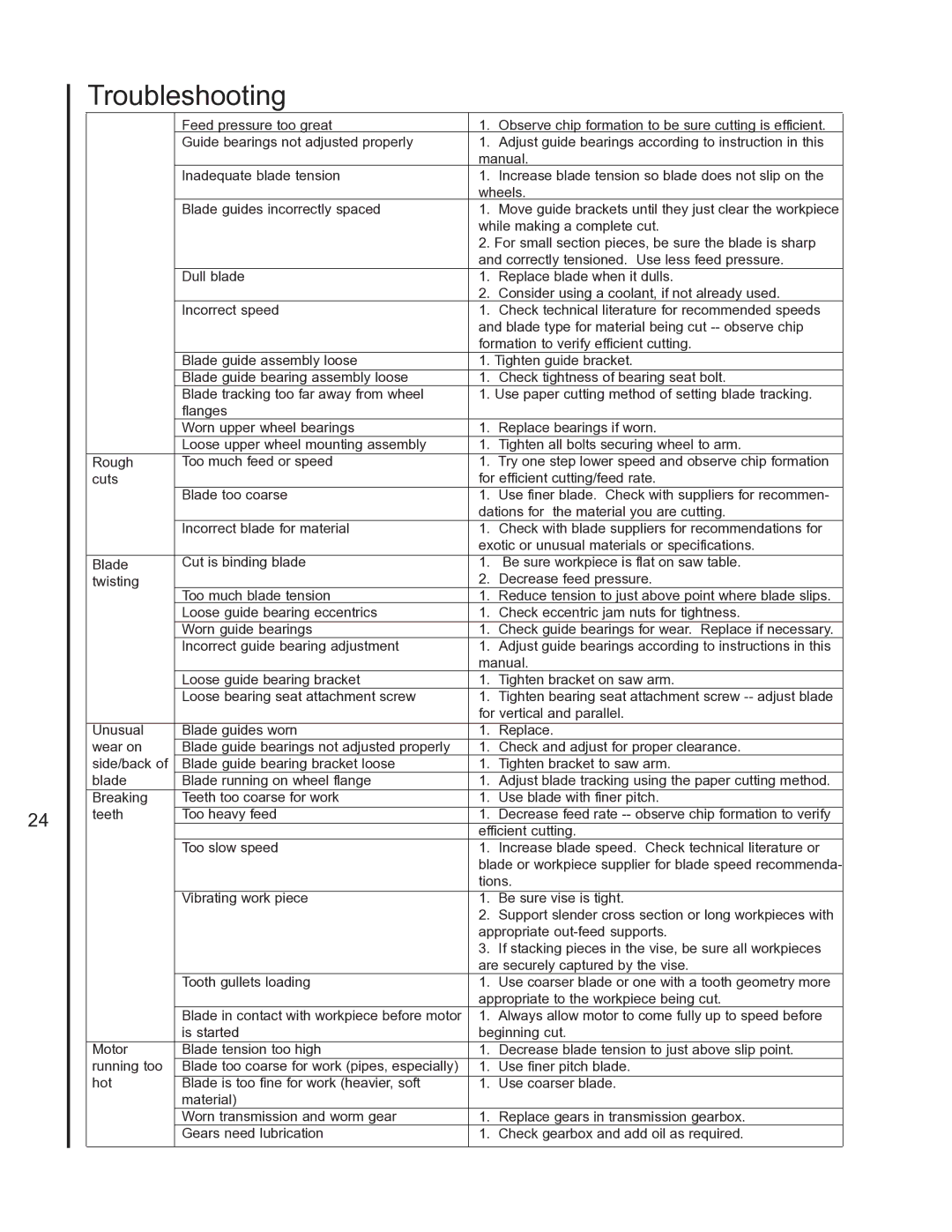

Troubleshooting

| Feed pressure too great | 1. | Observe chip formation to be sure cutting is efficient. |

| Guide bearings not adjusted properly | 1. | Adjust guide bearings according to instruction in this |

|

| manual. | |

| Inadequate blade tension | 1. | Increase blade tension so blade does not slip on the |

|

| wheels. | |

| Blade guides incorrectly spaced | 1. | Move guide brackets until they just clear the workpiece |

|

| while making a complete cut. | |

|

| 2. | For small section pieces, be sure the blade is sharp |

|

| and correctly tensioned. Use less feed pressure. | |

| Dull blade | 1. | Replace blade when it dulls. |

|

| 2. | Consider using a coolant, if not already used. |

| Incorrect speed | 1. | Check technical literature for recommended speeds |

|

| and blade type for material being cut | |

|

| formation to verify efficient cutting. | |

| Blade guide assembly loose | 1. Tighten guide bracket. | |

| Blade guide bearing assembly loose | 1. | Check tightness of bearing seat bolt. |

| Blade tracking too far away from wheel | 1. | Use paper cutting method of setting blade tracking. |

| flanges |

|

|

| Worn upper wheel bearings | 1. | Replace bearings if worn. |

| Loose upper wheel mounting assembly | 1. | Tighten all bolts securing wheel to arm. |

Rough | Too much feed or speed | 1. | Try one step lower speed and observe chip formation |

cuts |

| for efficient cutting/feed rate. | |

| Blade too coarse | 1. | Use finer blade. Check with suppliers for recommen- |

|

| dations for the material you are cutting. | |

| Incorrect blade for material | 1. | Check with blade suppliers for recommendations for |

|

| exotic or unusual materials or specifications. | |

Blade | Cut is binding blade | 1. | Be sure workpiece is flat on saw table. |

twisting |

| 2. | Decrease feed pressure. |

| Too much blade tension | 1. | Reduce tension to just above point where blade slips. |

| Loose guide bearing eccentrics | 1. | Check eccentric jam nuts for tightness. |

| Worn guide bearings | 1. | Check guide bearings for wear. Replace if necessary. |

| Incorrect guide bearing adjustment | 1. | Adjust guide bearings according to instructions in this |

|

| manual. | |

| Loose guide bearing bracket | 1. | Tighten bracket on saw arm. |

| Loose bearing seat attachment screw | 1. | Tighten bearing seat attachment screw |

|

| for vertical and parallel. | |

Unusual | Blade guides worn | 1. | Replace. |

wear on | Blade guide bearings not adjusted properly | 1. | Check and adjust for proper clearance. |

side/back of | Blade guide bearing bracket loose | 1. | Tighten bracket to saw arm. |

blade | Blade running on wheel flange | 1. | Adjust blade tracking using the paper cutting method. |

Breaking | Teeth too coarse for work | 1. | Use blade with finer pitch. |

teeth | Too heavy feed | 1. | Decrease feed rate |

|

| efficient cutting. | |

| Too slow speed | 1. | Increase blade speed. Check technical literature or |

|

| blade or workpiece supplier for blade speed recommenda- | |

|

| tions. | |

| Vibrating work piece | 1. | Be sure vise is tight. |

|

| 2. | Support slender cross section or long workpieces with |

|

| appropriate | |

|

| 3. | If stacking pieces in the vise, be sure all workpieces |

|

| are securely captured by the vise. | |

| Tooth gullets loading | 1. | Use coarser blade or one with a tooth geometry more |

|

| appropriate to the workpiece being cut. | |

| Blade in contact with workpiece before motor | 1. | Always allow motor to come fully up to speed before |

| is started | beginning cut. | |

Motor | Blade tension too high | 1. | Decrease blade tension to just above slip point. |

running too | Blade too coarse for work (pipes, especially) | 1. | Use finer pitch blade. |

hot | Blade is too fine for work (heavier, soft | 1. | Use coarser blade. |

| material) |

|

|

| Worn transmission and worm gear | 1. | Replace gears in transmission gearbox. |

| Gears need lubrication | 1. | Check gearbox and add oil as required. |

|

|

|

|