20

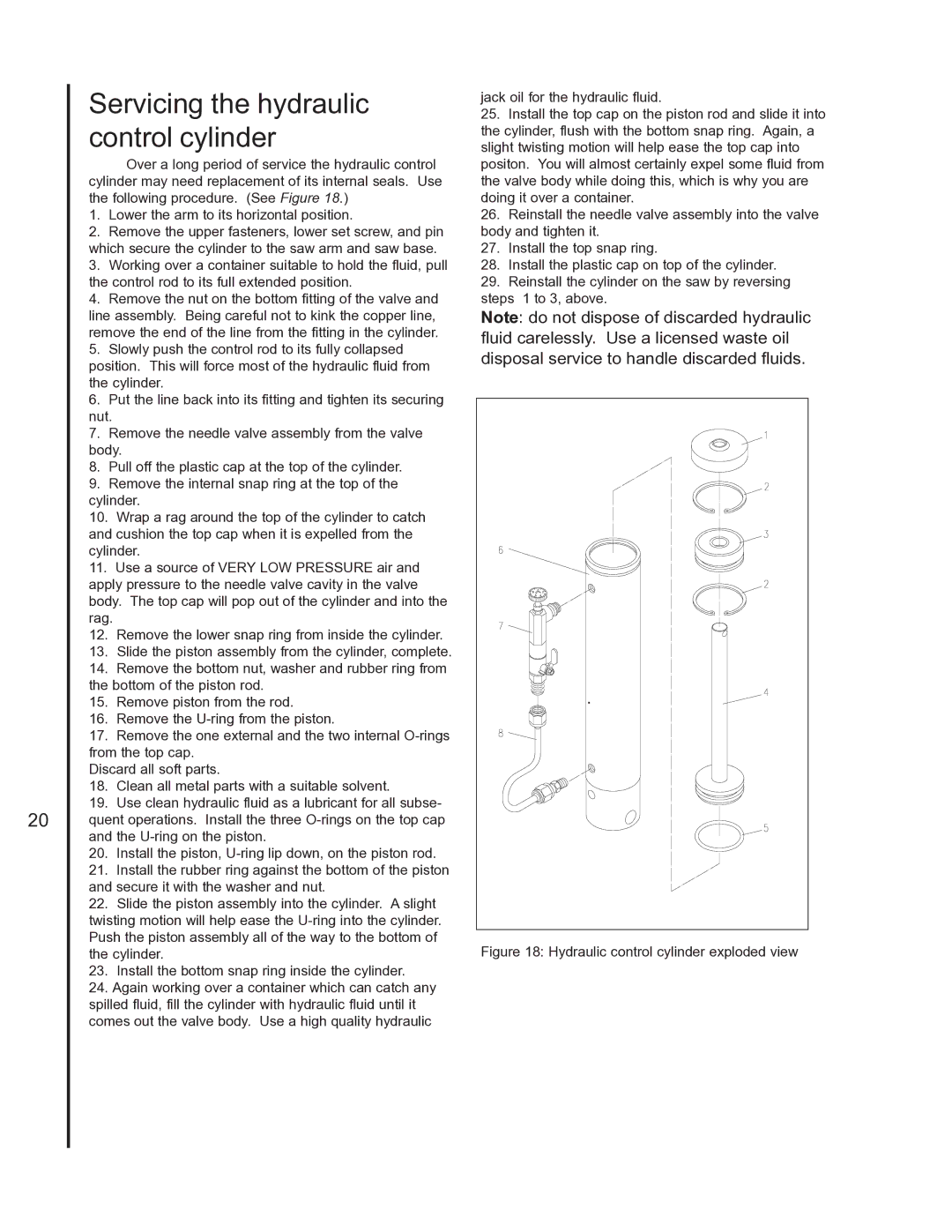

Servicing the hydraulic control cylinder

Over a long period of service the hydraulic control cylinder may need replacement of its internal seals. Use the following procedure. (See Figure 18.)

1.Lower the arm to its horizontal position.

2.Remove the upper fasteners, lower set screw, and pin which secure the cylinder to the saw arm and saw base.

3.Working over a container suitable to hold the fluid, pull the control rod to its full extended position.

4.Remove the nut on the bottom fitting of the valve and line assembly. Being careful not to kink the copper line, remove the end of the line from the fitting in the cylinder.

5.Slowly push the control rod to its fully collapsed position. This will force most of the hydraulic fluid from the cylinder.

6.Put the line back into its fitting and tighten its securing nut.

7.Remove the needle valve assembly from the valve body.

8.Pull off the plastic cap at the top of the cylinder.

9.Remove the internal snap ring at the top of the cylinder.

10.Wrap a rag around the top of the cylinder to catch and cushion the top cap when it is expelled from the cylinder.

11.Use a source of VERY LOW PRESSURE air and apply pressure to the needle valve cavity in the valve body. The top cap will pop out of the cylinder and into the rag.

12.Remove the lower snap ring from inside the cylinder.

13.Slide the piston assembly from the cylinder, complete.

14.Remove the bottom nut, washer and rubber ring from the bottom of the piston rod.

15.Remove piston from the rod.

16.Remove the

17.Remove the one external and the two internal

Discard all soft parts.

18.Clean all metal parts with a suitable solvent.

19.Use clean hydraulic fluid as a lubricant for all subse- quent operations. Install the three

20.Install the piston,

21.Install the rubber ring against the bottom of the piston and secure it with the washer and nut.

22.Slide the piston assembly into the cylinder. A slight twisting motion will help ease the

23.Install the bottom snap ring inside the cylinder.

24.Again working over a container which can catch any spilled fluid, fill the cylinder with hydraulic fluid until it comes out the valve body. Use a high quality hydraulic

jack oil for the hydraulic fluid.

25.Install the top cap on the piston rod and slide it into the cylinder, flush with the bottom snap ring. Again, a slight twisting motion will help ease the top cap into positon. You will almost certainly expel some fluid from the valve body while doing this, which is why you are doing it over a container.

26.Reinstall the needle valve assembly into the valve body and tighten it.

27.Install the top snap ring.

28.Install the plastic cap on top of the cylinder.

29.Reinstall the cylinder on the saw by reversing steps 1 to 3, above.

Note: do not dispose of discarded hydraulic fluid carelessly. Use a licensed waste oil disposal service to handle discarded fluids.