Replacing blade guide and support components

All component parts are secured with nuts, bolts, washers, or snap rings. To remove and replace any component, first remove the blade according to instruc- tions in Replacing blades. Then remove and replace the faulty component(s).

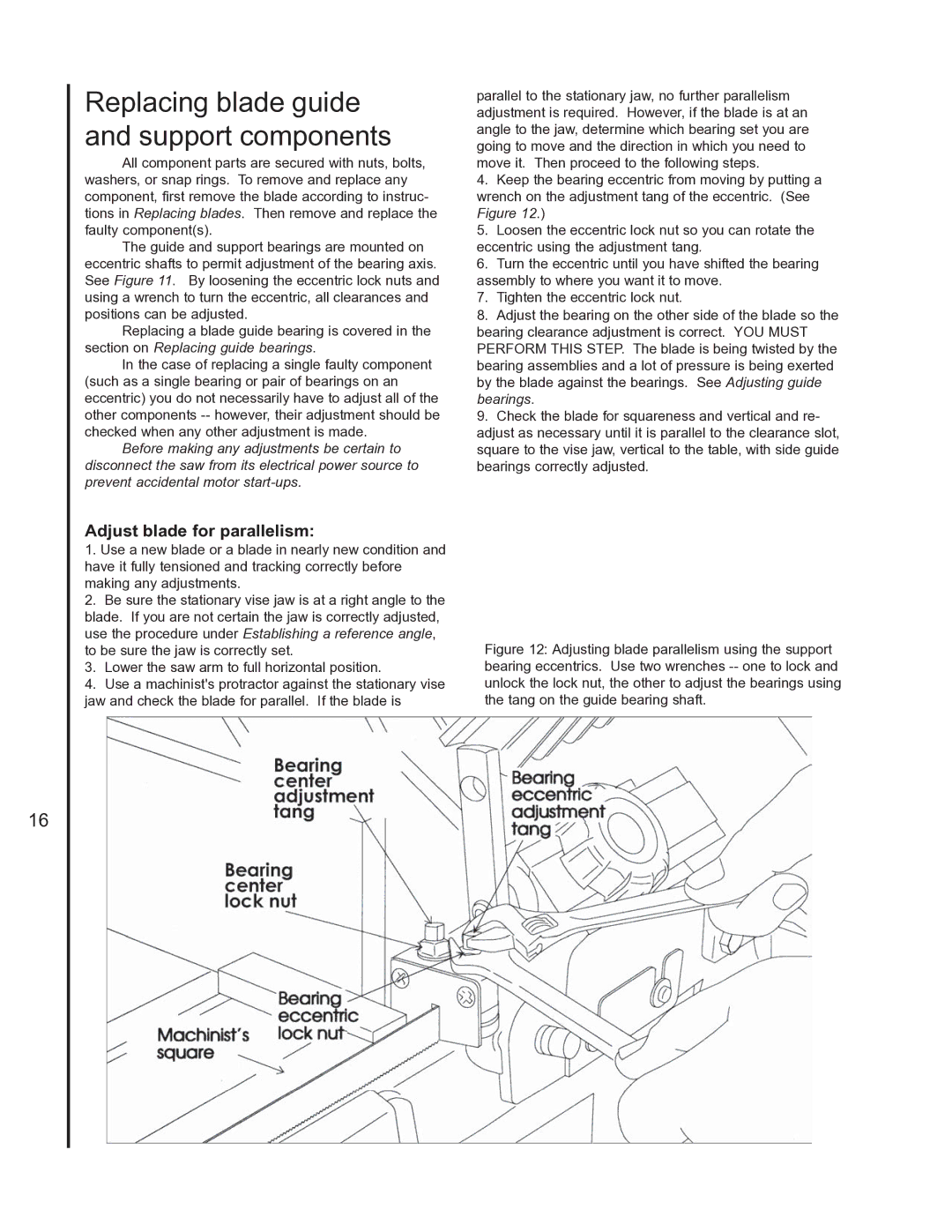

The guide and support bearings are mounted on eccentric shafts to permit adjustment of the bearing axis. See Figure 11. By loosening the eccentric lock nuts and using a wrench to turn the eccentric, all clearances and positions can be adjusted.

Replacing a blade guide bearing is covered in the section on Replacing guide bearings.

In the case of replacing a single faulty component (such as a single bearing or pair of bearings on an eccentric) you do not necessarily have to adjust all of the other components

Before making any adjustments be certain to disconnect the saw from its electrical power source to prevent accidental motor

parallel to the stationary jaw, no further parallelism adjustment is required. However, if the blade is at an angle to the jaw, determine which bearing set you are going to move and the direction in which you need to move it. Then proceed to the following steps.

4.Keep the bearing eccentric from moving by putting a wrench on the adjustment tang of the eccentric. (See Figure 12.)

5.Loosen the eccentric lock nut so you can rotate the eccentric using the adjustment tang.

6.Turn the eccentric until you have shifted the bearing assembly to where you want it to move.

7.Tighten the eccentric lock nut.

8.Adjust the bearing on the other side of the blade so the bearing clearance adjustment is correct. YOU MUST PERFORM THIS STEP. The blade is being twisted by the bearing assemblies and a lot of pressure is being exerted by the blade against the bearings. See Adjusting guide bearings.

9.Check the blade for squareness and vertical and re-

adjust as necessary until it is parallel to the clearance slot, square to the vise jaw, vertical to the table, with side guide bearings correctly adjusted.

16

Adjust blade for parallelism:

1.Use a new blade or a blade in nearly new condition and have it fully tensioned and tracking correctly before making any adjustments.

2.Be sure the stationary vise jaw is at a right angle to the blade. If you are not certain the jaw is correctly adjusted, use the procedure under Establishing a reference angle, to be sure the jaw is correctly set.

3.Lower the saw arm to full horizontal position.

4.Use a machinist's protractor against the stationary vise jaw and check the blade for parallel. If the blade is