Application data (cont)

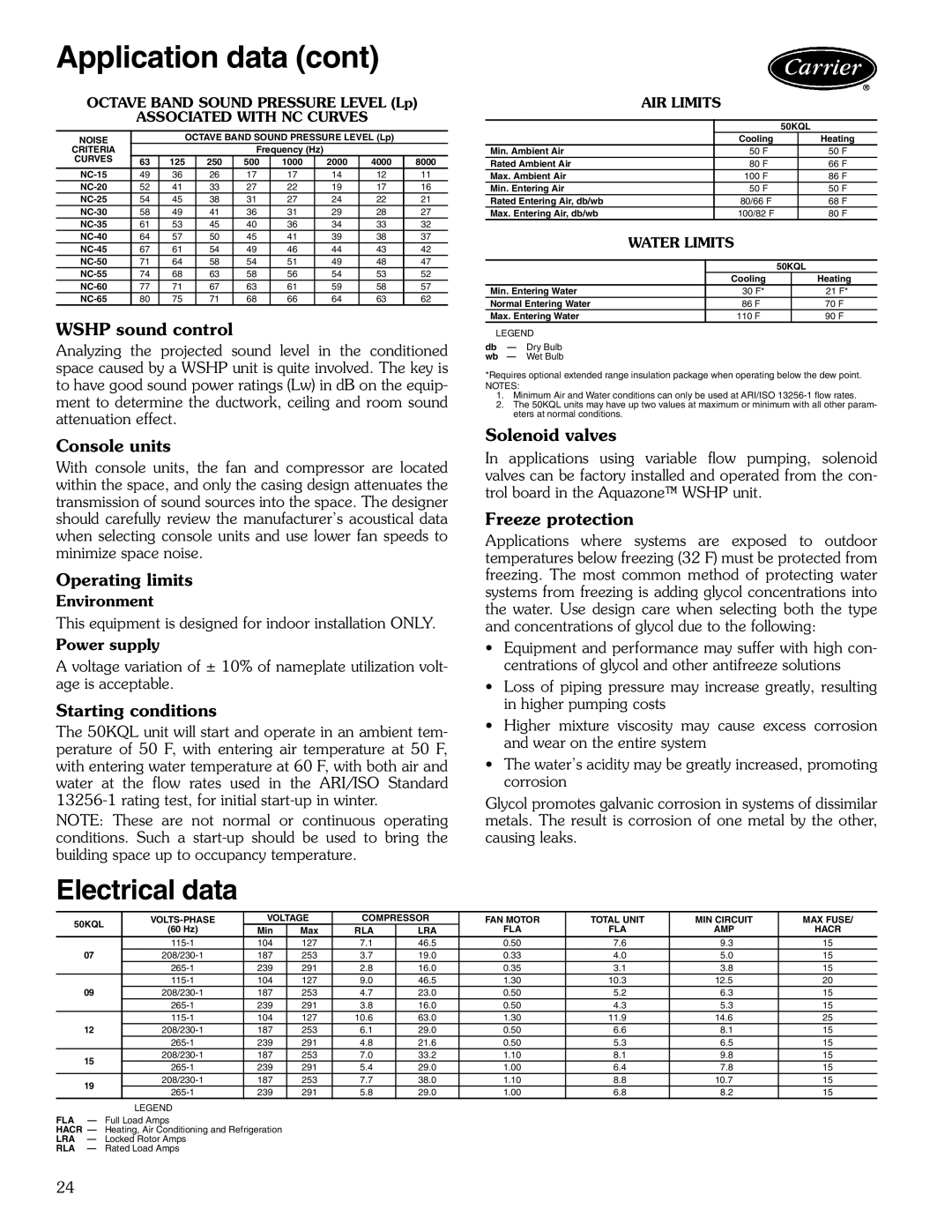

OCTAVE BAND SOUND PRESSURE LEVEL (Lp)

ASSOCIATED WITH NC CURVES

NOISE |

|

| OCTAVE BAND SOUND PRESSURE LEVEL (Lp) |

| ||||||

CRITERIA |

|

|

|

| Frequency (Hz) |

|

|

| ||

CURVES |

| 63 | 125 | 250 | 500 | 1000 |

| 2000 | 4000 | 8000 |

|

|

| ||||||||

49 | 36 | 26 | 17 | 17 |

| 14 | 12 | 11 | ||

52 | 41 | 33 | 27 | 22 |

| 19 | 17 | 16 | ||

54 | 45 | 38 | 31 | 27 |

| 24 | 22 | 21 | ||

58 | 49 | 41 | 36 | 31 |

| 29 | 28 | 27 | ||

61 | 53 | 45 | 40 | 36 |

| 34 | 33 | 32 | ||

64 | 57 | 50 | 45 | 41 |

| 39 | 38 | 37 | ||

67 | 61 | 54 | 49 | 46 |

| 44 | 43 | 42 | ||

71 | 64 | 58 | 54 | 51 |

| 49 | 48 | 47 | ||

74 | 68 | 63 | 58 | 56 |

| 54 | 53 | 52 | ||

77 | 71 | 67 | 63 | 61 |

| 59 | 58 | 57 | ||

80 | 75 | 71 | 68 | 66 |

| 64 | 63 | 62 | ||

WSHP sound control

Analyzing the projected sound level in the conditioned space caused by a WSHP unit is quite involved. The key is to have good sound power ratings (Lw) in dB on the equip- ment to determine the ductwork, ceiling and room sound attenuation effect.

Console units

With console units, the fan and compressor are located within the space, and only the casing design attenuates the transmission of sound sources into the space. The designer should carefully review the manufacturer’s acoustical data when selecting console units and use lower fan speeds to minimize space noise.

Operating limits

Environment

This equipment is designed for indoor installation ONLY.

Power supply

A voltage variation of ± 10% of nameplate utilization volt- age is acceptable.

Starting conditions

The 50KQL unit will start and operate in an ambient tem- perature of 50 F, with entering air temperature at 50 F, with entering water temperature at 60 F, with both air and water at the flow rates used in the ARI/ISO Standard

NOTE: These are not normal or continuous operating conditions. Such a

AIR LIMITS

|

| 50KQL | |

| Cooling |

| Heating |

Min. Ambient Air | 50 F |

| 50 F |

Rated Ambient Air | 80 F |

| 66 F |

Max. Ambient Air | 100 F |

| 86 F |

Min. Entering Air | 50 F |

| 50 F |

Rated Entering Air, db/wb | 80/66 F |

| 68 F |

Max. Entering Air, db/wb | 100/82 F |

| 80 F |

WATER LIMITS

|

|

|

| 50KQL | |

|

|

| Cooling |

| Heating |

Min. Entering Water | 30 F* |

| 21 F* | ||

Normal Entering Water | 86 F |

| 70 F | ||

Max. Entering Water | 110 F |

| 90 F | ||

LEGEND |

|

|

| ||

db | — | Dry Bulb |

|

|

|

wb | — | Wet Bulb |

|

|

|

*Requires optional extended range insulation package when operating below the dew point.

NOTES:

1.Minimum Air and Water conditions can only be used at ARI/ISO

2.The 50KQL units may have up two values at maximum or minimum with all other param- eters at normal conditions.

Solenoid valves

In applications using variable flow pumping, solenoid valves can be factory installed and operated from the con- trol board in the Aquazone™ WSHP unit.

Freeze protection

Applications where systems are exposed to outdoor temperatures below freezing (32 F) must be protected from freezing. The most common method of protecting water systems from freezing is adding glycol concentrations into the water. Use design care when selecting both the type and concentrations of glycol due to the following:

•Equipment and performance may suffer with high con- centrations of glycol and other antifreeze solutions

•Loss of piping pressure may increase greatly, resulting in higher pumping costs

•Higher mixture viscosity may cause excess corrosion and wear on the entire system

•The water’s acidity may be greatly increased, promoting corrosion

Glycol promotes galvanic corrosion in systems of dissimilar metals. The result is corrosion of one metal by the other, causing leaks.

Electrical data

50KQL |

| VOLTAGE | COMPRESSOR | FAN MOTOR | TOTAL UNIT | MIN CIRCUIT | MAX FUSE/ | |||

|

| (60 Hz) | Min | Max | RLA | LRA | FLA | FLA | AMP | HACR |

|

| 104 | 127 | 7.1 | 46.5 | 0.50 | 7.6 | 9.3 | 15 | |

07 |

| 187 | 253 | 3.7 | 19.0 | 0.33 | 4.0 | 5.0 | 15 | |

|

| 239 | 291 | 2.8 | 16.0 | 0.35 | 3.1 | 3.8 | 15 | |

|

| 104 | 127 | 9.0 | 46.5 | 1.30 | 10.3 | 12.5 | 20 | |

09 |

| 187 | 253 | 4.7 | 23.0 | 0.50 | 5.2 | 6.3 | 15 | |

|

| 239 | 291 | 3.8 | 16.0 | 0.50 | 4.3 | 5.3 | 15 | |

|

| 104 | 127 | 10.6 | 63.0 | 1.30 | 11.9 | 14.6 | 25 | |

12 |

| 187 | 253 | 6.1 | 29.0 | 0.50 | 6.6 | 8.1 | 15 | |

|

| 239 | 291 | 4.8 | 21.6 | 0.50 | 5.3 | 6.5 | 15 | |

15 |

| 187 | 253 | 7.0 | 33.2 | 1.10 | 8.1 | 9.8 | 15 | |

| 239 | 291 | 5.4 | 29.0 | 1.00 | 6.4 | 7.8 | 15 | ||

|

| |||||||||

19 |

| 187 | 253 | 7.7 | 38.0 | 1.10 | 8.8 | 10.7 | 15 | |

| 239 | 291 | 5.8 | 29.0 | 1.00 | 6.8 | 8.2 | 15 | ||

|

| |||||||||

|

| LEGEND |

|

|

|

|

|

|

|

|

FLA — Full Load Amps |

|

|

|

|

|

|

|

| ||

HACR — Heating, Air Conditioning and Refrigeration |

|

|

|

|

|

|

| |||

LRA — Locked Rotor Amps |

|

|

|

|

|

|

|

| ||

RLA — | Rated Load Amps |

|

|

|

|

|

|

|

| |

24