2.Install

NOTE: If flex hoses are used, unions are not necessary.

3.Install strainers at the inlet of each system circulating pump.

IMPORTANT: Since loop temperatures are normally between 60 and 90 F, pipe sweating and heat loss do not occur at normal ambient temperature conditions. Insulation must be installed on loop water piping on those sections that run through unheated areas or are located outside the building. If loop temperatures are expected below the ambient dew point, the optional internal insulation (extended range) package must be ordered.

![]() CAUTION

CAUTION

DO NOT bend or kink supply lines or hoses. Damage to unit may result.

4.Before making the final water connections, flush the sys- tem as described in the

NOTE: When necessary, use adapters to connect hoses.

5.Install any other system components, as required, follow- ing manufacturer’s instructions.

6.Reinstall the front cabinet by carefully lowering the front cabinet over the chassis onto the backplate.

Step 7 — Install Condensate Piping — Connect the unit condensate drain to the building condensate drain with a flexible,

The horizontal run of the condensate hose is usually too short to pose any drainage problems, however, the horizontal run of condensate line should be pitched at least 1 in. for every 10 ft of run (in the direction of flow). Avoid low points and un- pitched piping since dirt collects in these areas and may cause stoppage and overflow.

Field installation of a trap or vent is not required unless specified by local codes. The 50PEC units are designed in a

1/2” Flexible Hose

PRE-START-UP

System Cleaning and Flushing — Cleaning and flushing the unit and system is the single most important step to ensure proper

![]() WARNING

WARNING

To prevent injury or death due to electrical shock or contact with moving parts, open unit disconnect before servicing unit.

Follow the instructions below to properly clean and flush the system:

![]() CAUTION

CAUTION

DO NOT FLUSH SYSTEM THROUGH THE UNIT!

1.Verify that electrical power to the units is disconnected, and that the circulation pump is deenergized.

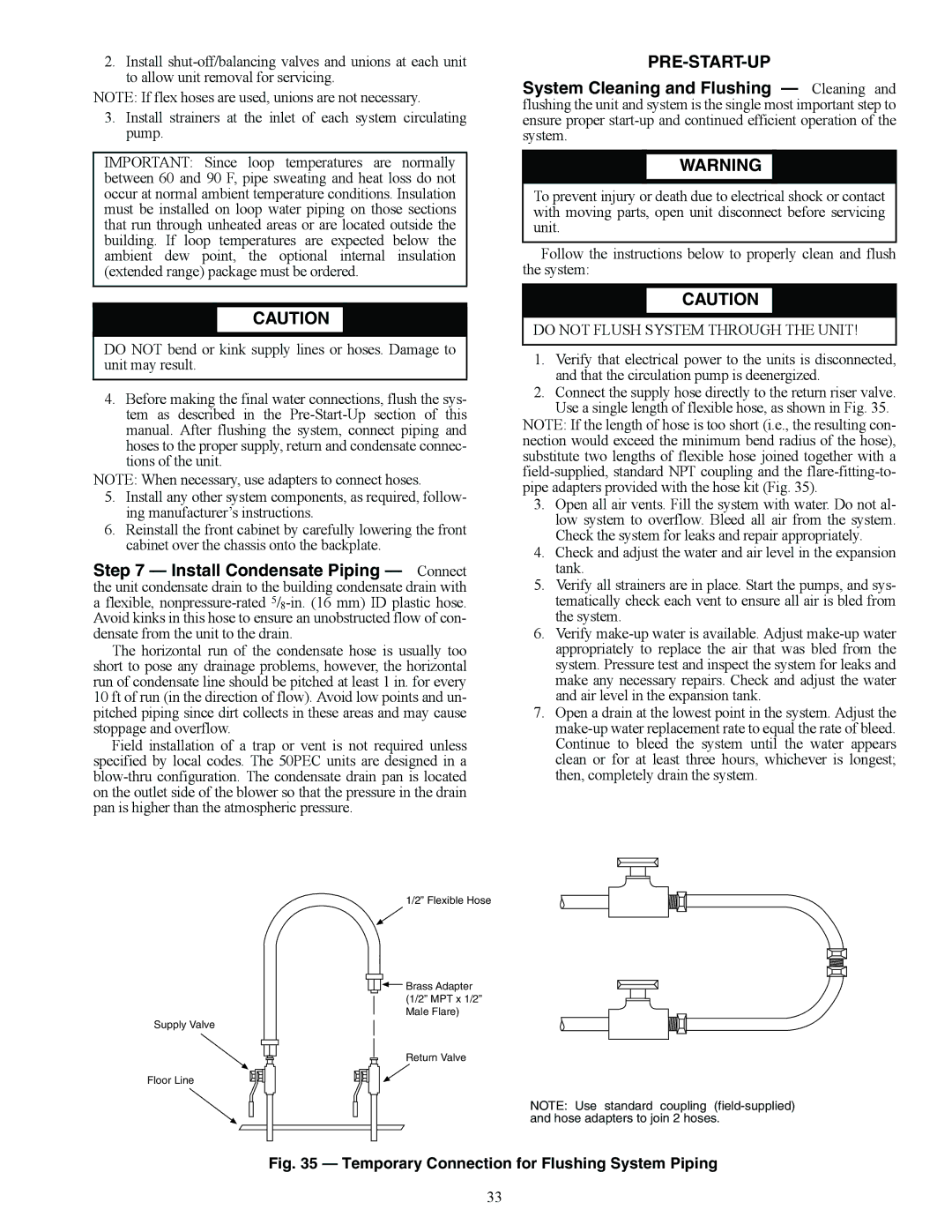

2.Connect the supply hose directly to the return riser valve. Use a single length of flexible hose, as shown in Fig. 35.

NOTE: If the length of hose is too short (i.e., the resulting con- nection would exceed the minimum bend radius of the hose), substitute two lengths of flexible hose joined together with a

3.Open all air vents. Fill the system with water. Do not al- low system to overflow. Bleed all air from the system. Check the system for leaks and repair appropriately.

4.Check and adjust the water and air level in the expansion tank.

5.Verify all strainers are in place. Start the pumps, and sys- tematically check each vent to ensure all air is bled from the system.

6.Verify

7.Open a drain at the lowest point in the system. Adjust the

![]() Brass Adapter

Brass Adapter

(1/2” MPT x 1/2”

Male Flare)

Supply Valve

Return Valve

Floor Line

NOTE: Use standard coupling

Fig. 35 — Temporary Connection for Flushing System Piping

33