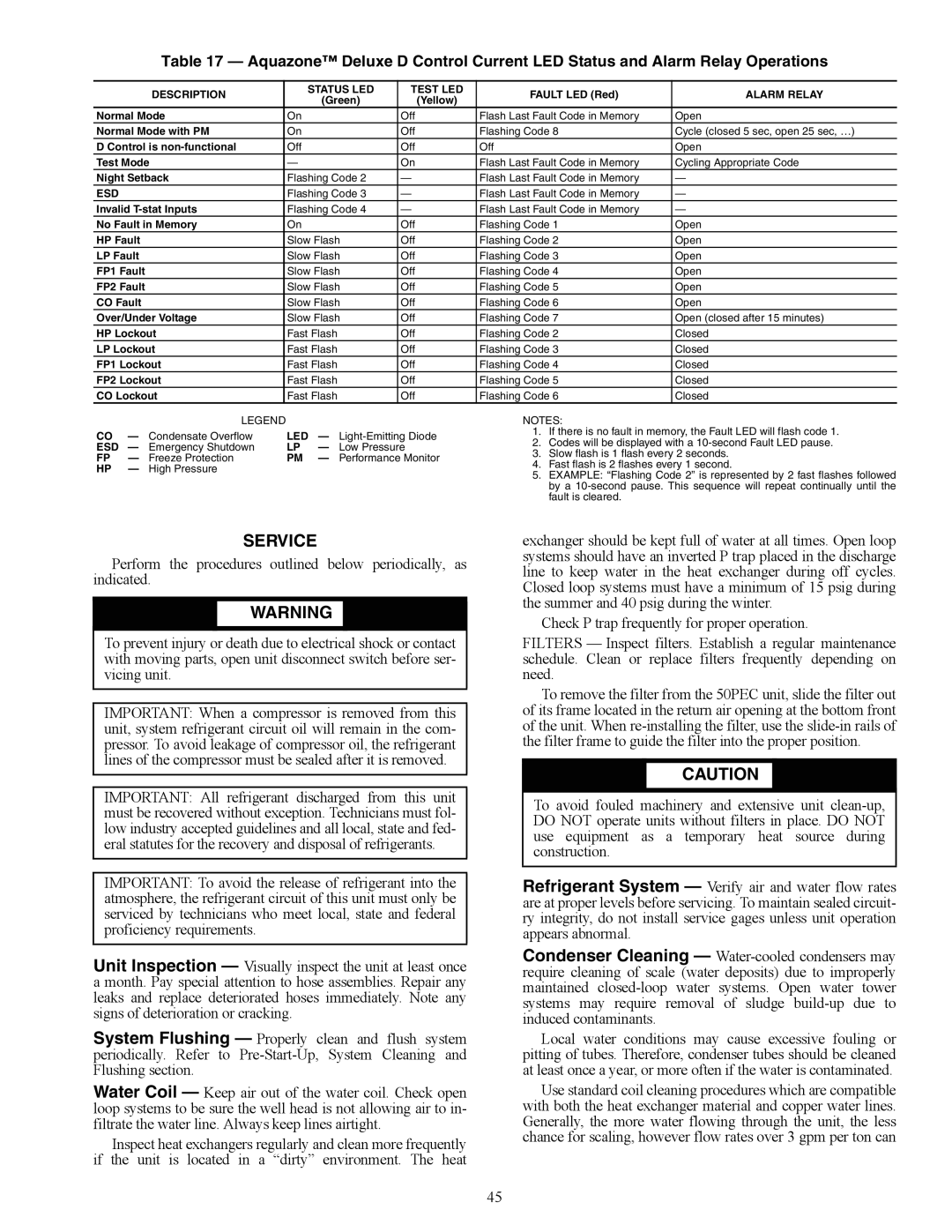

Table 17 — Aquazone™ Deluxe D Control Current LED Status and Alarm Relay Operations

DESCRIPTION | STATUS LED | TEST LED | FAULT LED (Red) | ALARM RELAY | |

(Green) | (Yellow) | ||||

|

|

| |||

Normal Mode | On | Off | Flash Last Fault Code in Memory | Open | |

Normal Mode with PM | On | Off | Flashing Code 8 | Cycle (closed 5 sec, open 25 sec, …) | |

D Control is | Off | Off | Off | Open | |

Test Mode | — | On | Flash Last Fault Code in Memory | Cycling Appropriate Code | |

Night Setback | Flashing Code 2 | — | Flash Last Fault Code in Memory | — | |

ESD | Flashing Code 3 | — | Flash Last Fault Code in Memory | — | |

Invalid | Flashing Code 4 | — | Flash Last Fault Code in Memory | — | |

No Fault in Memory | On | Off | Flashing Code 1 | Open | |

HP Fault | Slow Flash | Off | Flashing Code 2 | Open | |

LP Fault | Slow Flash | Off | Flashing Code 3 | Open | |

FP1 Fault | Slow Flash | Off | Flashing Code 4 | Open | |

FP2 Fault | Slow Flash | Off | Flashing Code 5 | Open | |

CO Fault | Slow Flash | Off | Flashing Code 6 | Open | |

Over/Under Voltage | Slow Flash | Off | Flashing Code 7 | Open (closed after 15 minutes) | |

HP Lockout | Fast Flash | Off | Flashing Code 2 | Closed | |

LP Lockout | Fast Flash | Off | Flashing Code 3 | Closed | |

FP1 Lockout | Fast Flash | Off | Flashing Code 4 | Closed | |

FP2 Lockout | Fast Flash | Off | Flashing Code 5 | Closed | |

CO Lockout | Fast Flash | Off | Flashing Code 6 | Closed |

|

| LEGEND |

|

|

| NOTES: | ||

CO | — | Condensate Overflow | LED | — | 1. | If there is no fault in memory, the Fault LED will flash code 1. | ||

2. | Codes will be displayed with a | |||||||

ESD | — | Emergency Shutdown | LP | — | Low Pressure | |||

3. | Slow flash is 1 flash every 2 seconds. | |||||||

FP | — | Freeze Protection | PM | — | Performance Monitor | |||

4. | Fast flash is 2 flashes every 1 second. | |||||||

HP | — | High Pressure |

|

|

| |||

|

|

| 5. | EXAMPLE: “Flashing Code 2” is represented by 2 fast flashes followed | ||||

|

|

|

|

|

| |||

by a

SERVICE

Perform the procedures outlined below periodically, as indicated.

![]() WARNING

WARNING

To prevent injury or death due to electrical shock or contact with moving parts, open unit disconnect switch before ser- vicing unit.

IMPORTANT: When a compressor is removed from this unit, system refrigerant circuit oil will remain in the com- pressor. To avoid leakage of compressor oil, the refrigerant lines of the compressor must be sealed after it is removed.

IMPORTANT: All refrigerant discharged from this unit must be recovered without exception. Technicians must fol- low industry accepted guidelines and all local, state and fed- eral statutes for the recovery and disposal of refrigerants.

IMPORTANT: To avoid the release of refrigerant into the atmosphere, the refrigerant circuit of this unit must only be serviced by technicians who meet local, state and federal proficiency requirements.

Unit Inspection — Visually inspect the unit at least once a month. Pay special attention to hose assemblies. Repair any leaks and replace deteriorated hoses immediately. Note any signs of deterioration or cracking.

System Flushing — Properly clean and flush system periodically. Refer to

Water Coil — Keep air out of the water coil. Check open loop systems to be sure the well head is not allowing air to in- filtrate the water line. Always keep lines airtight.

Inspect heat exchangers regularly and clean more frequently if the unit is located in a “dirty” environment. The heat

exchanger should be kept full of water at all times. Open loop systems should have an inverted P trap placed in the discharge line to keep water in the heat exchanger during off cycles. Closed loop systems must have a minimum of 15 psig during the summer and 40 psig during the winter.

Check P trap frequently for proper operation.

FILTERS — Inspect filters. Establish a regular maintenance schedule. Clean or replace filters frequently depending on need.

To remove the filter from the 50PEC unit, slide the filter out of its frame located in the return air opening at the bottom front of the unit. When

![]() CAUTION

CAUTION

To avoid fouled machinery and extensive unit

Refrigerant System — Verify air and water flow rates are at proper levels before servicing. To maintain sealed circuit- ry integrity, do not install service gages unless unit operation appears abnormal.

Condenser Cleaning —

Local water conditions may cause excessive fouling or pitting of tubes. Therefore, condenser tubes should be cleaned at least once a year, or more often if the water is contaminated.

Use standard coil cleaning procedures which are compatible with both the heat exchanger material and copper water lines. Generally, the more water flowing through the unit, the less chance for scaling, however flow rates over 3 gpm per ton can

45