•EXH blower motor is turned on.

•The

•The stop/jog option will periodically rotate the ERV wheel to clean it during wheel bypass operation. This feature is factory set to activate every 10 minutes, for 20 seconds of operation. Both settings can be adjusted from 0 to 10 minutes.

UNOCCUPIED MODE — While in unoccupied mode, when below the low temperature lockout set point, the ERV wheel is off, and only the

When above the low temperature lockout set point and cooling is desired the economizer or wheel bypass option is also used. Depending on the option used with the 62M ERV, several sequences of operation could occur.

Unoccupied Mode, with the Economizer Accessory — When using the economizer option, this allows for up to 100% out- side air to be brought in for free cooling. During free cooling, no mechanical cooling is operating and the following occurs:

•ERV wheel is turned off.

•Outdoor air blower motor is off.

•EXH blower motor is off.

•

•

•The stop/jog option will periodically rotate the ERV wheel to clean it during wheel bypass operation.

When using the economizer option and mechanical cooling is operating, the economizer should be closed or at the mini- mum position.

Unoccupied Mode, with the Wheel Bypass Option — When using the wheel bypass option (with the stop/jog option), this allows free cooling through the wheel limited by the ERV cfm limits. With this option the unit can be in free cooling or not depending on the temperature of the OA compared to the set point. When in free cooling:

•ERV wheel is turned off.

•Outdoor air blower is on.

•EXH blower motor is on.

•

When not in free cooling:

To install the segments see the Installing Wheel Segments

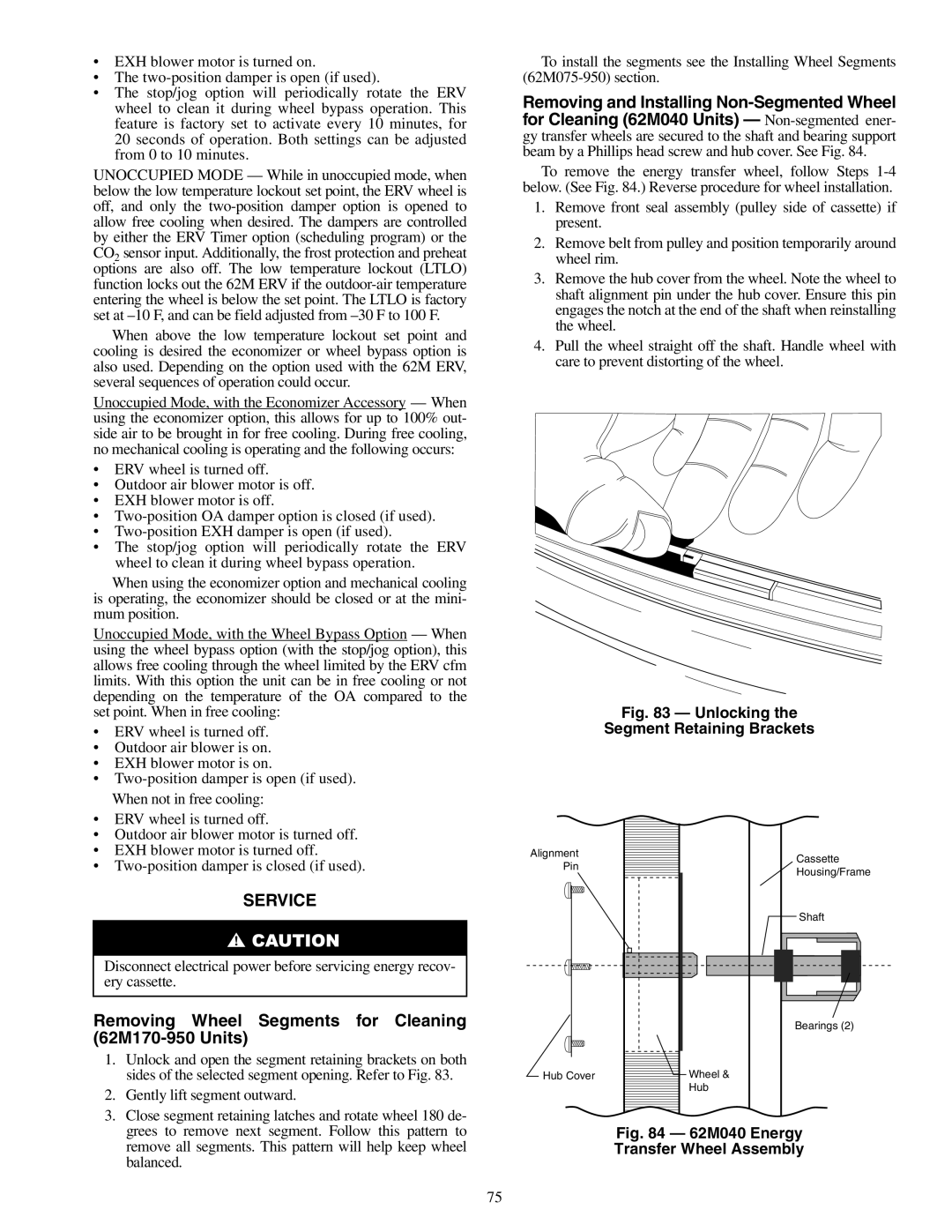

Removing and Installing

To remove the energy transfer wheel, follow Steps

1.Remove front seal assembly (pulley side of cassette) if present.

2.Remove belt from pulley and position temporarily around wheel rim.

3.Remove the hub cover from the wheel. Note the wheel to shaft alignment pin under the hub cover. Ensure this pin engages the notch at the end of the shaft when reinstalling the wheel.

4.Pull the wheel straight off the shaft. Handle wheel with care to prevent distorting of the wheel.

Fig. 83 — Unlocking the

Segment Retaining Brackets

•ERV wheel is turned off.

•Outdoor air blower motor is turned off.

•EXH blower motor is turned off.

•

SERVICE

Disconnect electrical power before servicing energy recov- ery cassette.

Removing Wheel Segments for Cleaning (62M170-950 Units)

1. | Unlock and open the segment retaining brackets on both |

| sides of the selected segment opening. Refer to Fig. 83. |

2. | Gently lift segment outward. |

3. | Close segment retaining latches and rotate wheel 180 de- |

Alignment

Pin

Hub Cover

Wheel & Hub

Cassette Housing/Frame

Shaft

Bearings (2)

grees to remove next segment. Follow this pattern to |

remove all segments. This pattern will help keep wheel |

balanced. |

Fig. 84 — 62M040 Energy Transfer Wheel Assembly

75