| Locking |

|

|

|

| Belt (Shown in | |

|

|

|

|

| Place) | ||

| Collar |

|

|

|

| ||

| Bearing |

|

| ||||

| Locking |

| Wheel Rim | ||||

| Support |

| |||||

|

|

| |||||

|

|

| |||||

Bearing | Nut (2) | Beam |

| Wheel | |||

| |||||||

Bearing |

|

|

|

| |||

|

|

|

|

| |||

Access Plate |

|

|

|

|

| ||

Housing |

|

|

|

| Hub (2) | ||

|

|

|

|

| |||

|

|

|

|

|

|

| |

|

|

|

|

|

|

| Taper - Lock |

|

|

|

|

|

|

| Hub Collar (2) |

|

|

|

|

|

|

| |

Retaining

Screws

Set Screw

Shaft

Drift Hole

Locating Pin

PULL

FEED

Belt

Pulley | Motor |

Side | Side |

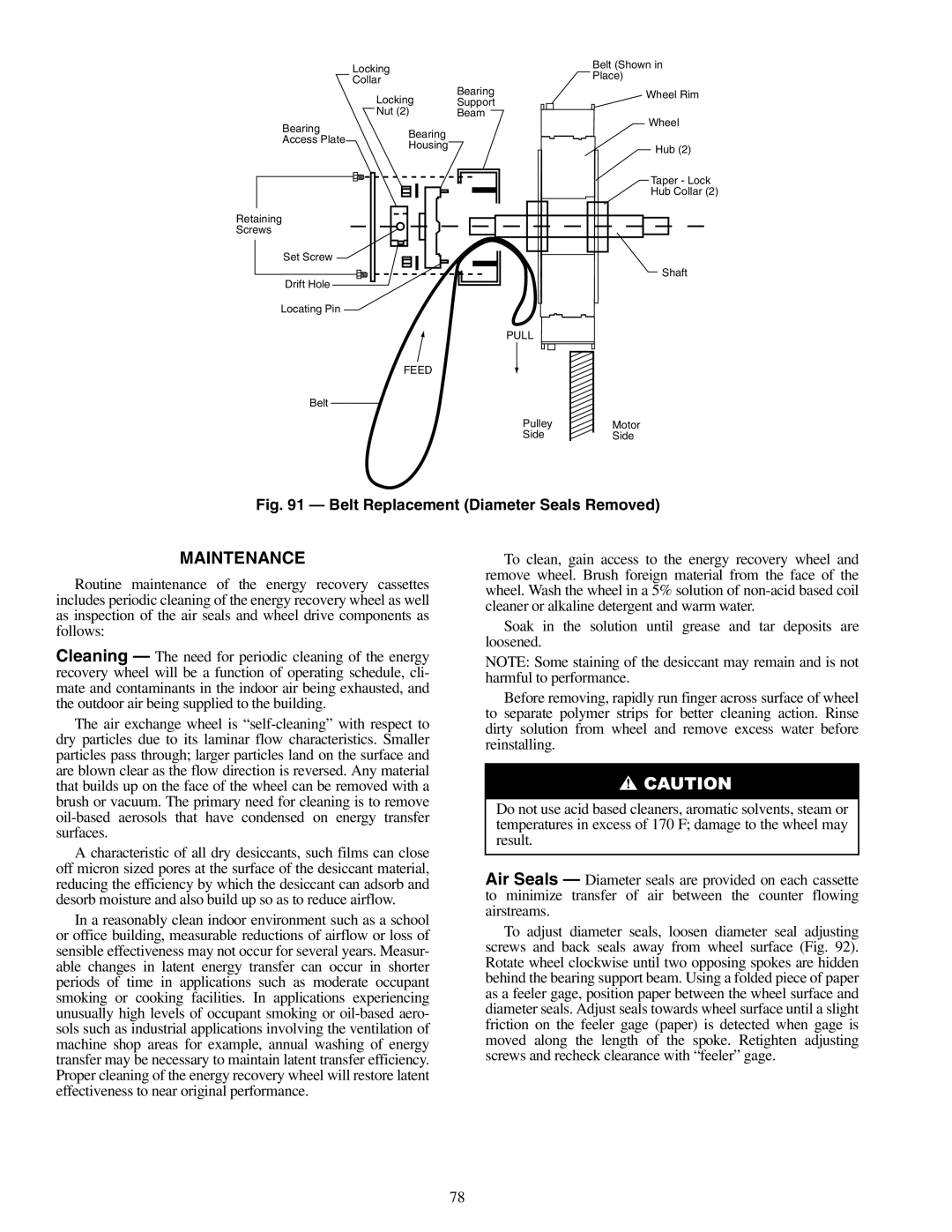

Fig. 91 — Belt Replacement (Diameter Seals Removed)

MAINTENANCE

Routine maintenance of the energy recovery cassettes includes periodic cleaning of the energy recovery wheel as well as inspection of the air seals and wheel drive components as follows:

Cleaning — The need for periodic cleaning of the energy recovery wheel will be a function of operating schedule, cli- mate and contaminants in the indoor air being exhausted, and the outdoor air being supplied to the building.

The air exchange wheel is

A characteristic of all dry desiccants, such films can close off micron sized pores at the surface of the desiccant material, reducing the efficiency by which the desiccant can adsorb and desorb moisture and also build up so as to reduce airflow.

In a reasonably clean indoor environment such as a school or office building, measurable reductions of airflow or loss of sensible effectiveness may not occur for several years. Measur- able changes in latent energy transfer can occur in shorter periods of time in applications such as moderate occupant smoking or cooking facilities. In applications experiencing unusually high levels of occupant smoking or

To clean, gain access to the energy recovery wheel and remove wheel. Brush foreign material from the face of the wheel. Wash the wheel in a 5% solution of

Soak in the solution until grease and tar deposits are loosened.

NOTE: Some staining of the desiccant may remain and is not harmful to performance.

Before removing, rapidly run finger across surface of wheel to separate polymer strips for better cleaning action. Rinse dirty solution from wheel and remove excess water before reinstalling.

Do not use acid based cleaners, aromatic solvents, steam or temperatures in excess of 170 F; damage to the wheel may result.

Air Seals — Diameter seals are provided on each cassette to minimize transfer of air between the counter flowing airstreams.

To adjust diameter seals, loosen diameter seal adjusting screws and back seals away from wheel surface (Fig. 92). Rotate wheel clockwise until two opposing spokes are hidden behind the bearing support beam. Using a folded piece of paper as a feeler gage, position paper between the wheel surface and diameter seals. Adjust seals towards wheel surface until a slight friction on the feeler gage (paper) is detected when gage is moved along the length of the spoke. Retighten adjusting screws and recheck clearance with “feeler” gage.

78