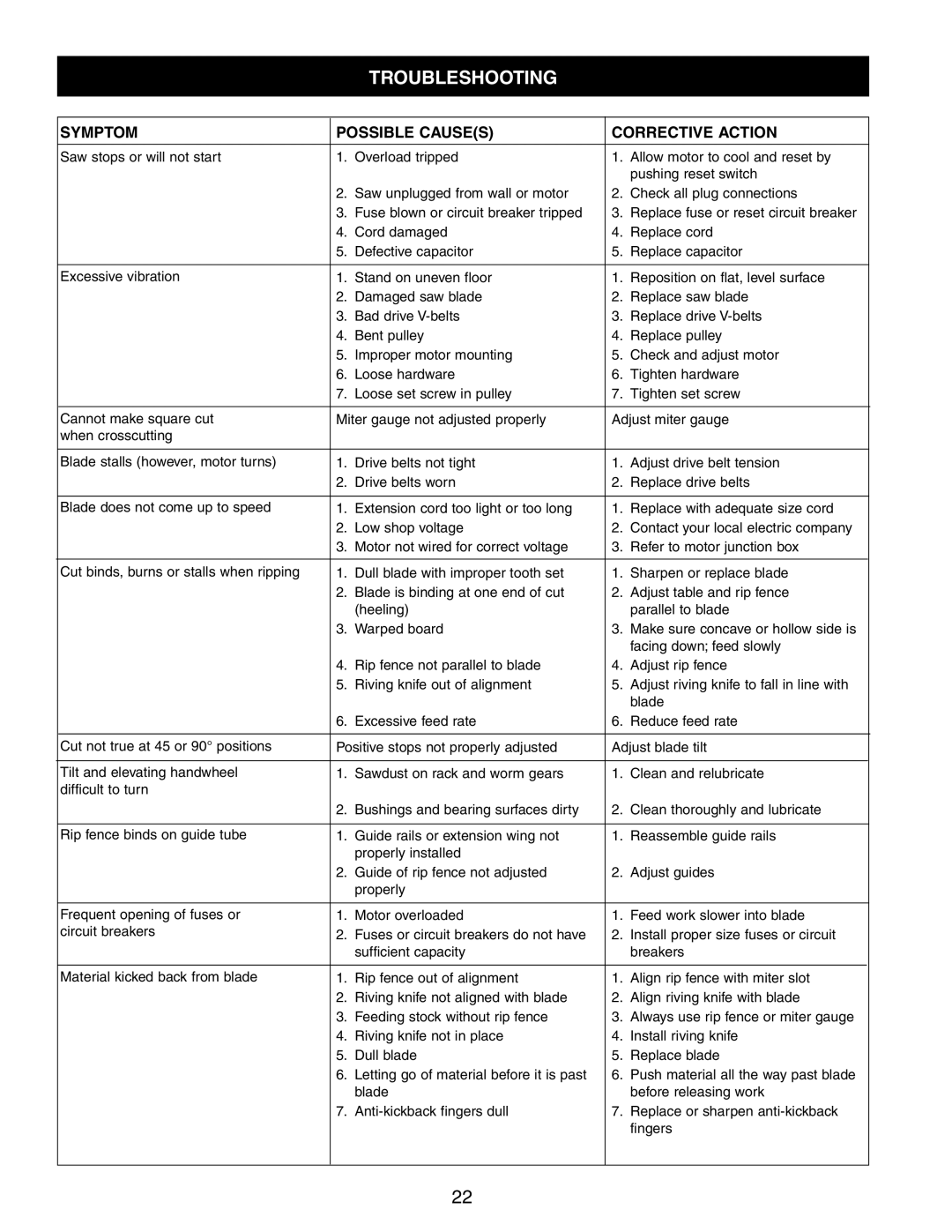

TROUBLESHOOTING

SYMPTOM | POSSIBLE CAUSE(S) | CORRECTIVE ACTION |

| ||

|

|

|

|

| |

Saw stops or will not start | 1. Overload tripped | 1. | Allow motor to cool and reset by |

| |

|

|

|

| pushing reset switch |

|

| 2. | Saw unplugged from wall or motor | 2. | Check all plug connections |

|

| 3. | Fuse blown or circuit breaker tripped | 3. | Replace fuse or reset circuit breaker |

|

| 4. | Cord damaged | 4. | Replace cord |

|

| 5. | Defective capacitor | 5. | Replace capacitor |

|

|

|

|

|

| |

Excessive vibration | 1. Stand on uneven floor | 1. | Reposition on flat, level surface |

| |

| 2. | Damaged saw blade | 2. | Replace saw blade |

|

| 3. | Bad drive | 3. | Replace drive |

|

| 4. | Bent pulley | 4. | Replace pulley |

|

| 5. | Improper motor mounting | 5. | Check and adjust motor |

|

| 6. | Loose hardware | 6. | Tighten hardware |

|

| 7. | Loose set screw in pulley | 7. | Tighten set screw |

|

|

|

|

| ||

Cannot make square cut | Miter gauge not adjusted properly | Adjust miter gauge |

| ||

when crosscutting |

|

|

|

|

|

|

|

|

|

|

|

Blade stalls (however, motor turns) | 1. | Drive belts not tight | 1. | Adjust drive belt tension |

|

| 2. | Drive belts worn | 2. | Replace drive belts |

|

|

|

|

|

| |

Blade does not come up to speed | 1. Extension cord too light or too long | 1. | Replace with adequate size cord |

| |

| 2. | Low shop voltage | 2. | Contact your local electric company |

|

| 3. | Motor not wired for correct voltage | 3. | Refer to motor junction box |

|

|

|

|

|

| |

Cut binds, burns or stalls when ripping | 1. Dull blade with improper tooth set | 1. | Sharpen or replace blade |

| |

| 2. | Blade is binding at one end of cut | 2. | Adjust table and rip fence |

|

|

| (heeling) |

| parallel to blade |

|

| 3. | Warped board | 3. | Make sure concave or hollow side is |

|

|

|

|

| facing down; feed slowly |

|

| 4. | Rip fence not parallel to blade | 4. | Adjust rip fence |

|

| 5. | Riving knife out of alignment | 5. | Adjust riving knife to fall in line with |

|

|

|

|

| blade |

|

| 6. | Excessive feed rate | 6. | Reduce feed rate |

|

|

|

|

| ||

Cut not true at 45 or 90¡ positions | Positive stops not properly adjusted | Adjust blade tilt |

| ||

|

|

|

|

| |

Tilt and elevating handwheel | 1. Sawdust on rack and worm gears | 1. | Clean and relubricate |

| |

difficult to turn |

|

|

|

|

|

| 2. | Bushings and bearing surfaces dirty | 2. | Clean thoroughly and lubricate |

|

|

|

|

|

| |

Rip fence binds on guide tube | 1. Guide rails or extension wing not | 1. | Reassemble guide rails |

| |

|

| properly installed |

|

|

|

| 2. | Guide of rip fence not adjusted | 2. | Adjust guides |

|

|

| properly |

|

|

|

|

|

|

|

| |

Frequent opening of fuses or | 1. Motor overloaded | 1. | Feed work slower into blade |

| |

circuit breakers | 2. | Fuses or circuit breakers do not have | 2. | Install proper size fuses or circuit |

|

|

| sufficient capacity |

| breakers |

|

|

|

|

|

| |

Material kicked back from blade | 1. Rip fence out of alignment | 1. | Align rip fence with miter slot |

| |

| 2. | Riving knife not aligned with blade | 2. | Align riving knife with blade |

|

| 3. | Feeding stock without rip fence | 3. | Always use rip fence or miter gauge |

|

| 4. | Riving knife not in place | 4. | Install riving knife |

|

| 5. | Dull blade | 5. | Replace blade |

|

| 6. | Letting go of material before it is past | 6. | Push material all the way past blade |

|

|

| blade |

| before releasing work |

|

| 7. | 7. | Replace or sharpen |

| |

|

|

|

| fingers |

|

|

|

|

|

|

|

22