CONTENTS | REMARKS |

|

|

5.Control way of Error (if any)

1)“F1” error

Cause :

Check point : Measure the resistance between both terminals after separating CN8 (or CN15) of the Main PCB. (Refer to the

If

2)“R1” error

Cause :

Check point : Measure the resistance between both terminals after separating CN7 (or CN14) of the Main PCB. (Refer to the

If

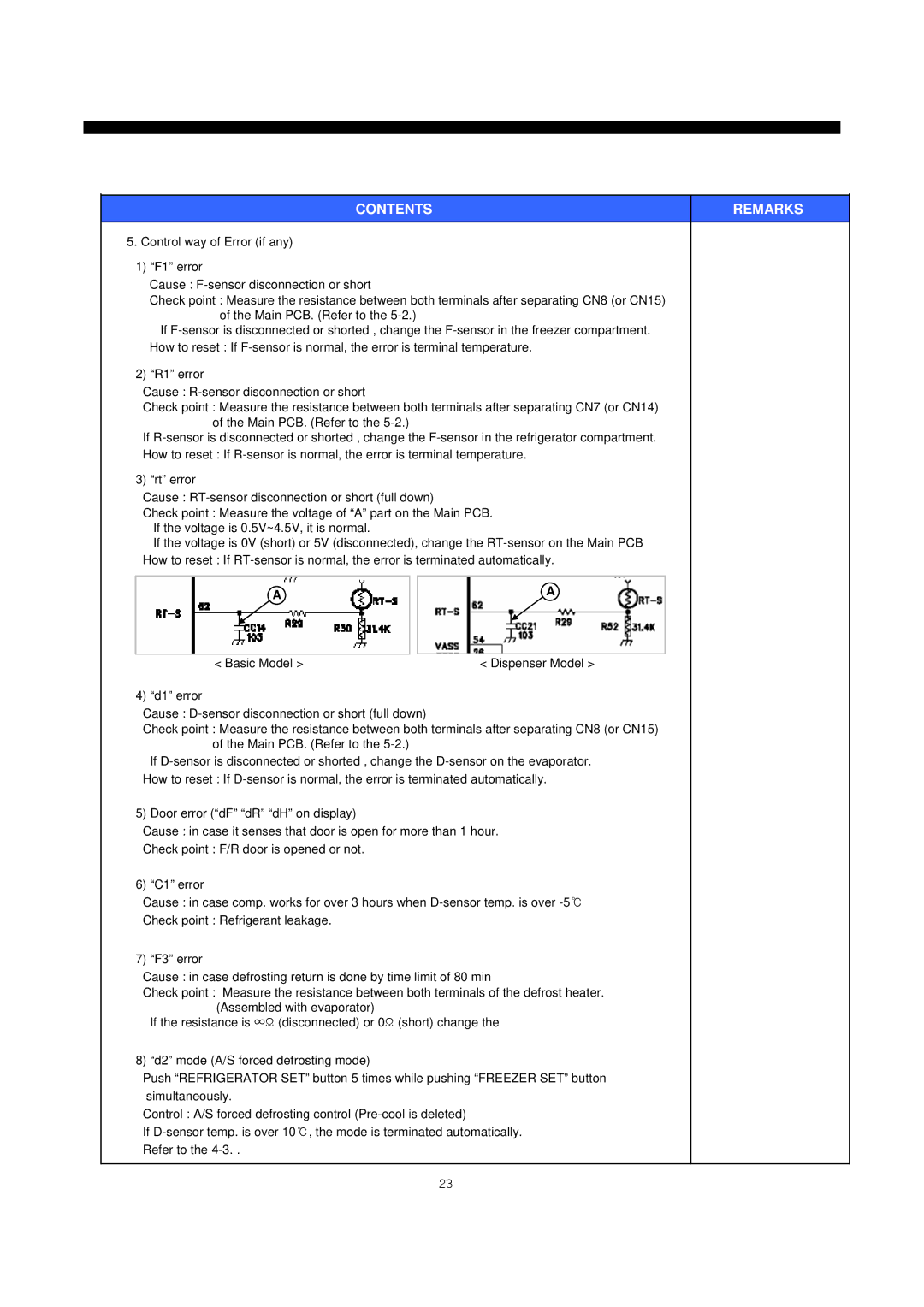

3) “rt” error

Cause :

Check point : Measure the voltage of “A” part on the Main PCB. If the voltage is 0.5V~4.5V, it is normal.

If the voltage is 0V (short) or 5V (disconnected), change the

A |

| A |

|

|

|

< Basic Model > |

| < Dispenser Model > |

4) “d1” error

Cause :

Check point : Measure the resistance between both terminals after separating CN8 (or CN15) of the Main PCB. (Refer to the

If

5) Door error (“dF” “dR” “dH” on display)

Cause : in case it senses that door is open for more than 1 hour.

Check point : F/R door is opened or not.

6) “C1” error

Cause : in case comp. works for over 3 hours when

Check point : Refrigerant leakage.

7) “F3” error

Cause : in case defrosting return is done by time limit of 80 min

Check point : Measure the resistance between both terminals of the defrost heater. (Assembled with evaporator)

If the resistance is ∞Ω (disconnected) or 0Ω (short) change the

8) “d2” mode (A/S forced defrosting mode)

Push “REFRIGERATOR SET” button 5 times while pushing “FREEZER SET” button simultaneously.

Control : A/S forced defrosting control

If

23