10-3. Practical Work for Heavy Repair

Items |

| Precautions | |

1. Removal of residual |

|

|

|

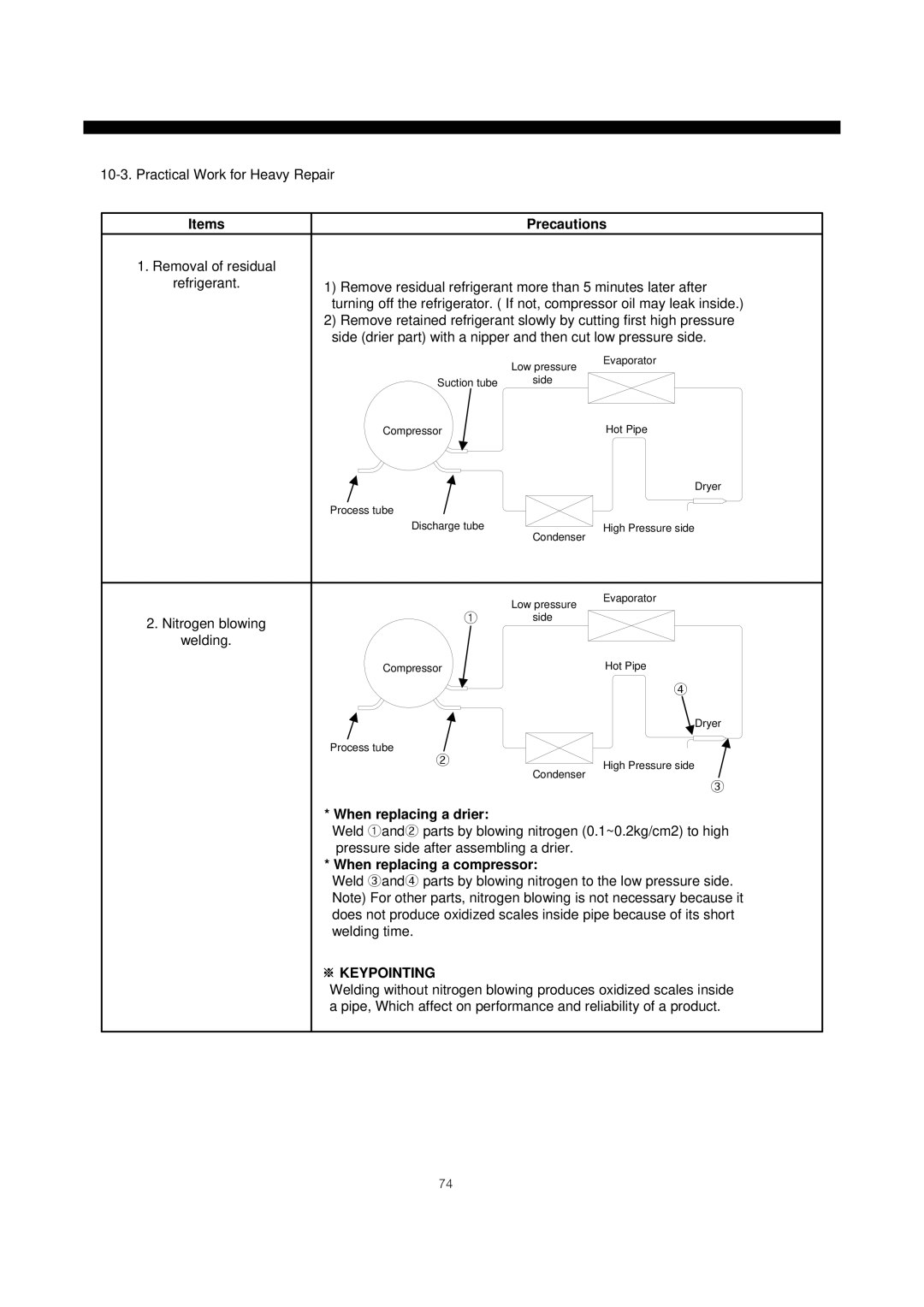

refrigerant. | 1) Remove residual refrigerant more than 5 minutes later after | ||

| turning off the refrigerator. ( If not, compressor oil may leak inside.) | ||

| 2) Remove retained refrigerant slowly by cutting first high pressure | ||

| side (drier part) with a nipper and then cut low pressure side. | ||

|

| Low pressure | Evaporator |

|

|

| |

| Suction tube | side |

|

| Compressor |

| Hot Pipe |

|

|

| Dryer |

| Process tube |

|

|

| Discharge tube | Condenser | High Pressure side |

|

|

| |

|

| Low pressure | Evaporator |

|

|

| |

2. Nitrogen blowing | ① | side |

|

|

|

| |

welding. |

|

|

|

| Compressor |

| Hot Pipe |

|

|

| ④ |

|

|

| Dryer |

| Process tube |

|

|

| ② |

| High Pressure side |

|

| Condenser | |

|

| ③ | |

|

|

| |

*When replacing a drier:

Weld ①and② parts by blowing nitrogen (0.1~0.2kg/cm2) to high pressure side after assembling a drier.

*When replacing a compressor:

Weld ③and④ parts by blowing nitrogen to the low pressure side. Note) For other parts, nitrogen blowing is not necessary because it does not produce oxidized scales inside pipe because of its short welding time.

※KEYPOINTING

Welding without nitrogen blowing produces oxidized scales inside a pipe, Which affect on performance and reliability of a product.

74