INSTALLATION

LOCATING GRILL/BUILT-IN CLEARANCES

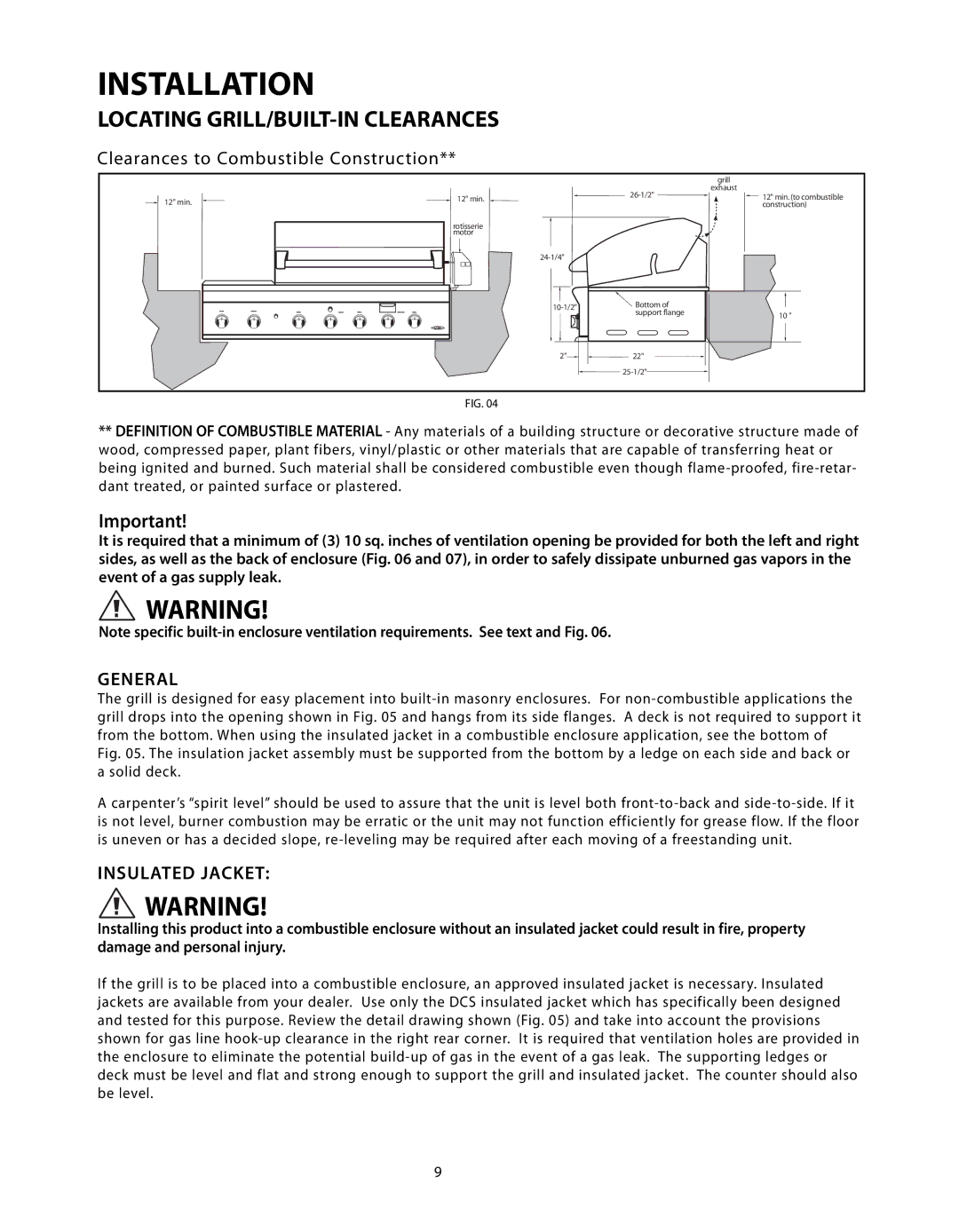

Clearances to Combustible Construction**

|

|

| grill |

|

| exhaust | |

12" min. | 12" min. | 12" min. (to combustible | |

|

| construction) | |

| rotisserie |

|

|

| motor |

|

|

|

|

| |

| Bottom of |

| |

| support flange | 10 " | |

|

| ||

|

|

| |

| 2" | 22" |

|

|

|

|

FIG. 04

**DEFINITION OF COMBUSTIBLE MATERIAL - Any materials of a building structure or decorative structure made of wood, compressed paper, plant fibers, vinyl/plastic or other materials that are capable of transferring heat or being ignited and burned. Such material shall be considered combustible even though

Important!

It is required that a minimum of (3) 10 sq. inches of ventilation opening be provided for both the left and right sides, as well as the back of enclosure (Fig. 06 and 07), in order to safely dissipate unburned gas vapors in the event of a gas supply leak.

![]() WARNING!

WARNING!

Note specific

GENERAL

The grill is designed for easy placement into

Acarpenter’s “spirit level” should be used to assure that the unit is level both

INSULATED JACKET:

![]() WARNING!

WARNING!

Installing this product into a combustible enclosure without an insulated jacket could result in fire, property damage and personal injury.

If the grill is to be placed into a combustible enclosure, an approved insulated jacket is necessary. Insulated jackets are available from your dealer. Use only the DCS insulated jacket which has specifically been designed and tested for this purpose. Review the detail drawing shown (Fig. 05) and take into account the provisions shown for gas line

9