MAINTENANCE

LUBRICATION

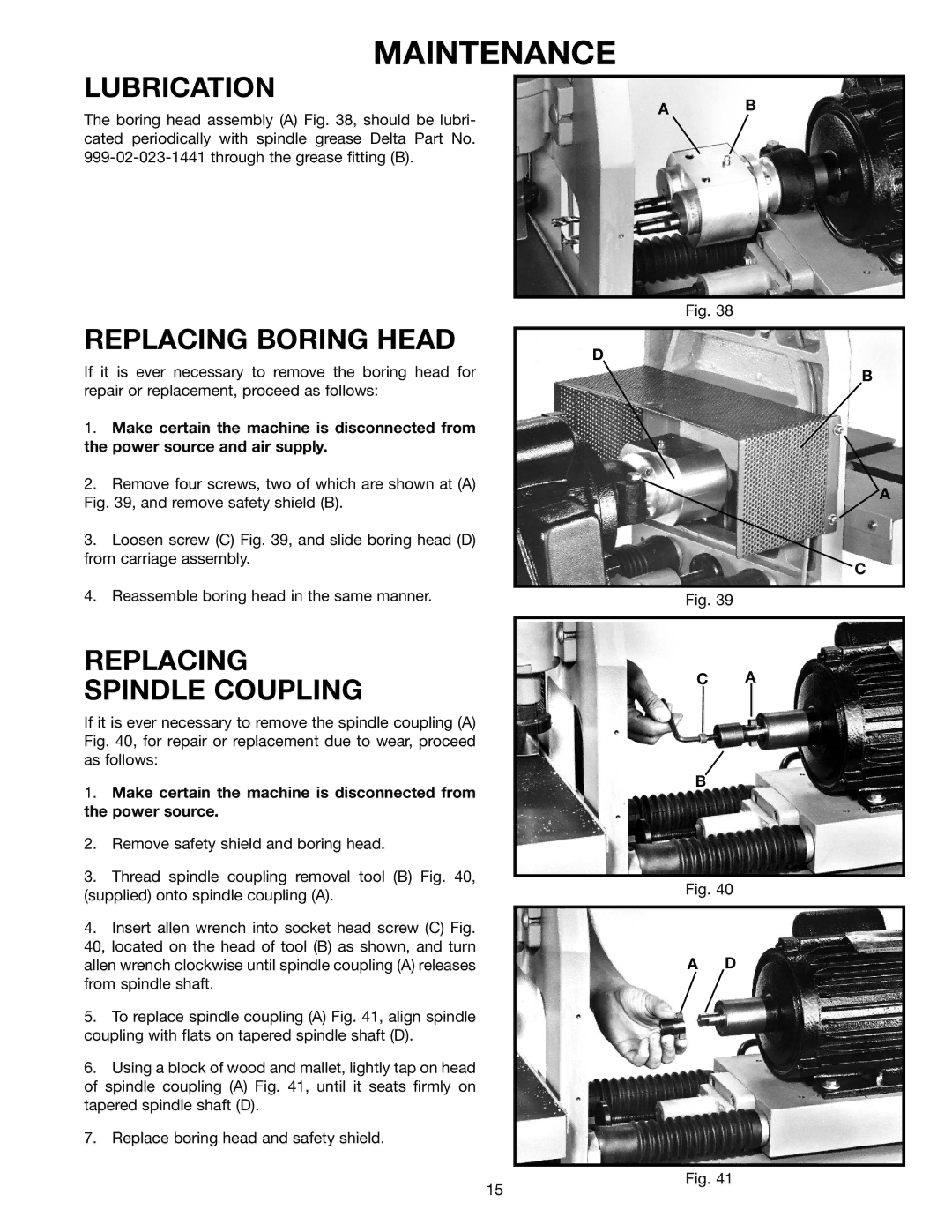

The boring head assembly (A) Fig. 38, should be lubri- cated periodically with spindle grease Delta Part No.

A B

Fig. 38

REPLACING BORING HEAD

If it is ever necessary to remove the boring head for repair or replacement, proceed as follows:

1.Make certain the machine is disconnected from the power source and air supply.

2.Remove four screws, two of which are shown at (A) Fig. 39, and remove safety shield (B).

3.Loosen screw (C) Fig. 39, and slide boring head (D) from carriage assembly.

4.Reassemble boring head in the same manner.

REPLACING

SPINDLE COUPLING

If it is ever necessary to remove the spindle coupling (A) Fig. 40, for repair or replacement due to wear, proceed as follows:

1.Make certain the machine is disconnected from the power source.

2.Remove safety shield and boring head.

3.Thread spindle coupling removal tool (B) Fig. 40, (supplied) onto spindle coupling (A).

4.Insert allen wrench into socket head screw (C) Fig. 40, located on the head of tool (B) as shown, and turn allen wrench clockwise until spindle coupling (A) releases from spindle shaft.

5.To replace spindle coupling (A) Fig. 41, align spindle coupling with flats on tapered spindle shaft (D).

6.Using a block of wood and mallet, lightly tap on head of spindle coupling (A) Fig. 41, until it seats firmly on tapered spindle shaft (D).

7.Replace boring head and safety shield.

15

D

B

![]() A

A

C

Fig. 39

CA

B

Fig. 40

A D

Fig. 41