ASSEMBLING

STOCK STOP TO TABLE

1. | Loosen two lock knobs (A) Fig. 11, located on the |

underside of table (B). | |

2. | With the flat side of stock stop rod (C) Fig. 11, facing |

down, slide stop rod (C) through holes at both ends of | |

table (B) as shown, and fasten by rotating two lock knobs | |

(A) clockwise. | |

D

E

B A

3. Assemble stock stop (D) Fig. 11, to either end of the |

stop rod (C) and hold in place by rotating lock knob (E) |

clockwise. NOTE: Lock knob (E) Fig. 11, must clamp |

against flat surface of stop rod (C). Adjustments to stock |

stop (D) can be made later. |

C

A

Fig. 11

CONNECTING MACHINE TO AIR SUPPLY

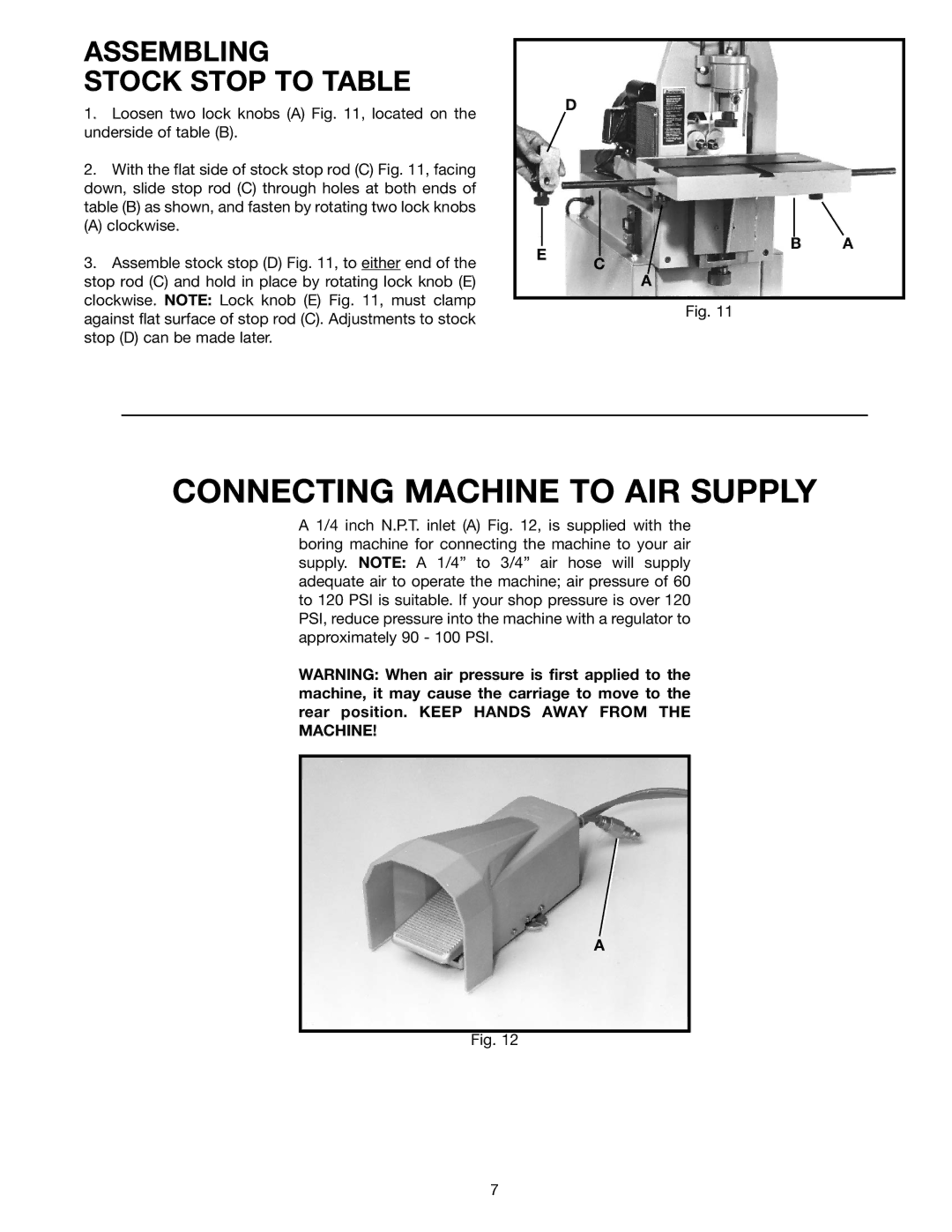

A 1/4 inch N.P.T. inlet (A) Fig. 12, is supplied with the boring machine for connecting the machine to your air supply. NOTE: A 1/4” to 3/4” air hose will supply adequate air to operate the machine; air pressure of 60 to 120 PSI is suitable. If your shop pressure is over 120 PSI, reduce pressure into the machine with a regulator to approximately 90 - 100 PSI.

WARNING: When air pressure is first applied to the machine, it may cause the carriage to move to the rear position. KEEP HANDS AWAY FROM THE MACHINE!

A

Fig. 12

7