OPERATING CONTROLS AND ADJUSTMENTS

INSTALLING AND REMOVING DRILL BITS

1.Make certain the machine is disconnected from the power source.

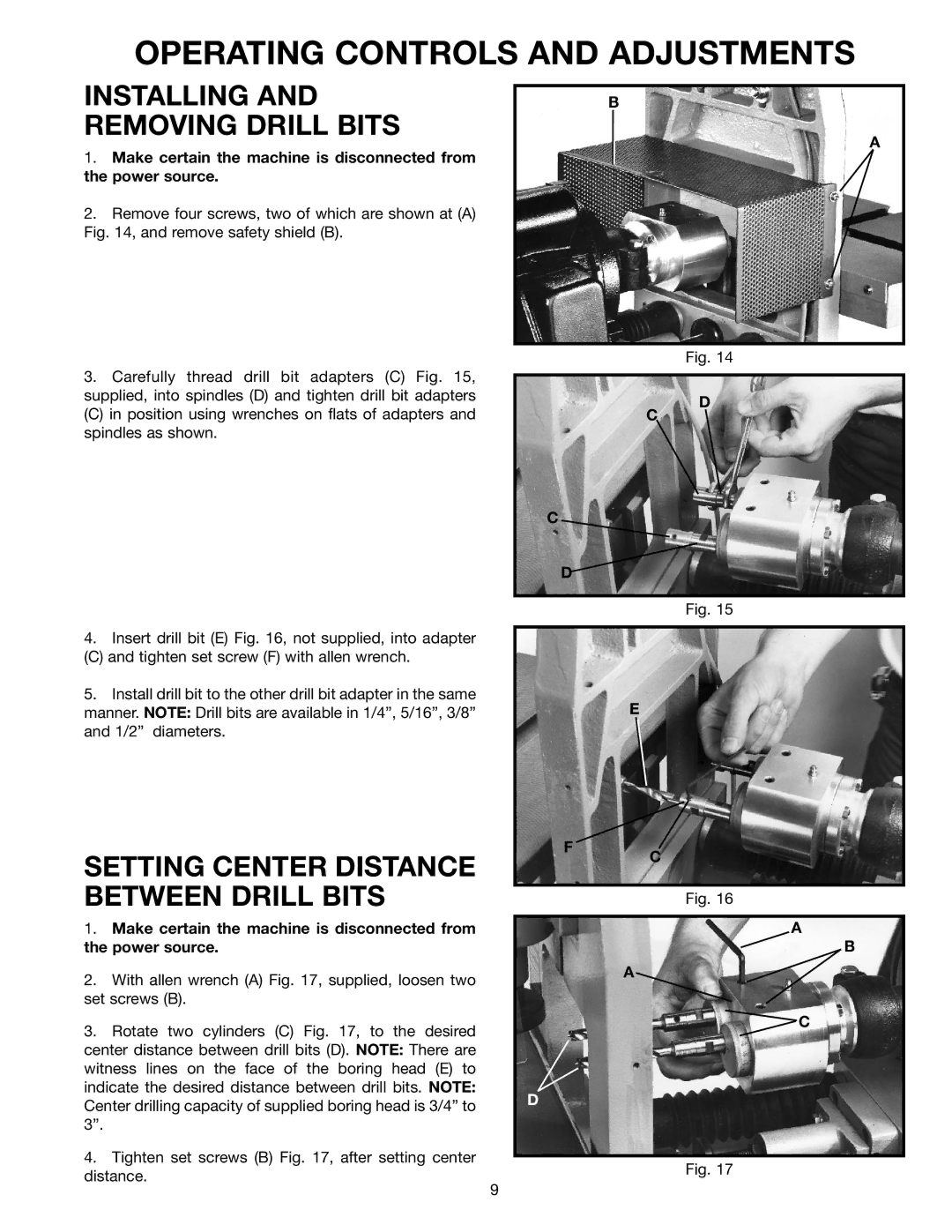

2.Remove four screws, two of which are shown at (A) Fig. 14, and remove safety shield (B).

3.Carefully thread drill bit adapters (C) Fig. 15, supplied, into spindles (D) and tighten drill bit adapters

(C) in position using wrenches on flats of adapters and spindles as shown.

4.Insert drill bit (E) Fig. 16, not supplied, into adapter

(C) and tighten set screw (F) with allen wrench.

5.Install drill bit to the other drill bit adapter in the same manner. NOTE: Drill bits are available in 1/4”, 5/16”, 3/8” and 1/2” diameters.

SETTING CENTER DISTANCE BETWEEN DRILL BITS

1.Make certain the machine is disconnected from the power source.

2.With allen wrench (A) Fig. 17, supplied, loosen two set screws (B).

3.Rotate two cylinders (C) Fig. 17, to the desired center distance between drill bits (D). NOTE: There are witness lines on the face of the boring head (E) to indicate the desired distance between drill bits. NOTE: Center drilling capacity of supplied boring head is 3/4” to 3”.

4.Tighten set screws (B) Fig. 17, after setting center distance.

B

A

Fig. 14

D

C

C

D

Fig. 15

E

F

C

Fig. 16

A

B

A

![]() C

C

D

Fig. 17

9