16

INSTALLATION

Checking Gas Connections

INSTALLATION

Continued

CHECKING GAS CONNECTIONS

![]() WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

3.Check all joints from gas meter to equipment shutoff valve for natural gas or propane/LP supply to equipment shutoff valve for propane/LP (see Figures 24 or 25). Apply noncorrosive leak detection fluid to all joints. Bubbles forming show a leak.

4.Correct all leaks at once.

![]() WARNING: Never use an open flame to check for a leak. Apply a noncorrosive leak detection fluid to all joints. Bubbles forming show a leak. Correct all leaks at once.

WARNING: Never use an open flame to check for a leak. Apply a noncorrosive leak detection fluid to all joints. Bubbles forming show a leak. Correct all leaks at once.

![]() CAUTION: Make sure external regulator has been installed between propane/LP supply and fireplace. See guidelines under Connecting to Gas Supply, pages 14 and 15.

CAUTION: Make sure external regulator has been installed between propane/LP supply and fireplace. See guidelines under Connecting to Gas Supply, pages 14 and 15.

Pressure Testing Gas Supply Piping system

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1. Disconnect appliance with its appliance main gas valve (control |

valve) and equipment shutoff valve from gas supply piping sys- |

Pressure Testing Fireplace Gas Connections

1.Open equipment shutoff valve (see Figure 23).

2.Open main gas valve located on or near gas meter for natural gas or open propane/LP supply tank valve.

3.Make sure control knob of fireplace is in the OFF position.

4.Check all joints from equipment shutoff valve to gas regulator

5.Correct all leaks at once.

6.Light fireplace (see Operating Fireplace, pages 19 through 23). Check all other internal joints for leaks.

7.Turn off fireplace (see To Turn Off Gas to Appliance, page 20 for

| tem. Pressures in excess of 1/2 psig will damage heater regulator. |

2. | Cap off open end of gas pipe where equipment shutoff valve |

| was connected. |

3. Pressurize supply piping system by either opening propane/ | |

| LP supply tank valve for propane/LP gas or opening main gas |

| valve located on or near gas meter for natural gas, or using |

| compressed air. |

4. | Check all joints of gas supply piping system. Apply noncorrosive |

| leak detection fluid to all joints. Bubbles forming show a leak. |

5. | Correct all leaks at once. |

6. | Reconnect fireplace and equipment shutoff valve to gas sup- |

| ply. Check reconnected fittings for leaks. |

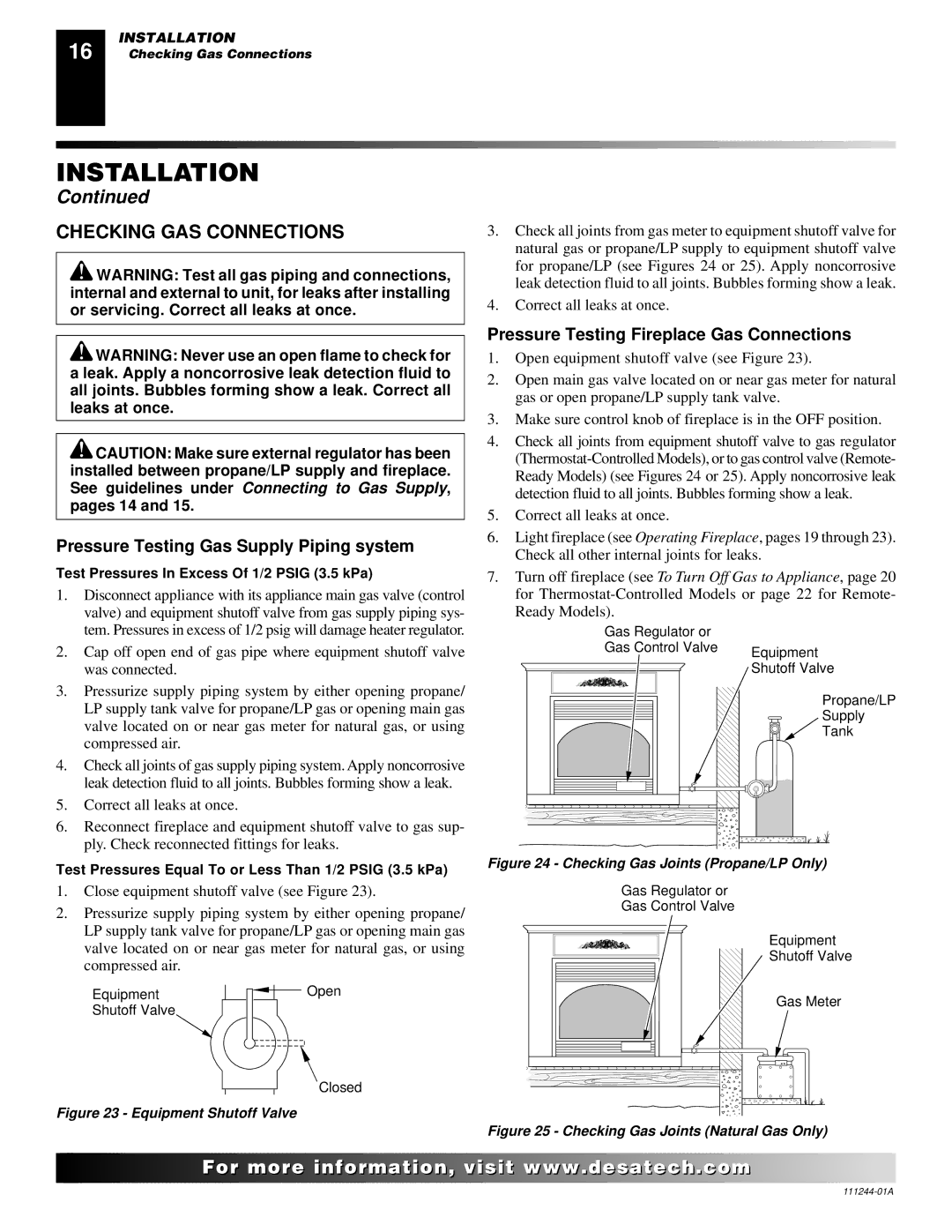

Gas Regulator or Gas Control Valve

Equipment

Shutoff Valve

Propane/LP

Supply

Tank

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1.Close equipment shutoff valve (see Figure 23).

2.Pressurize supply piping system by either opening propane/ LP supply tank valve for propane/LP gas or opening main gas valve located on or near gas meter for natural gas, or using compressed air.

Equipment |

| Open |

| ||

Shutoff Valve |

|

|

Closed

Figure 23 - Equipment Shutoff Valve

Figure 24 - Checking Gas Joints (Propane/LP Only)

Gas Regulator or

Gas Control Valve

Equipment

Shutoff Valve

Gas Meter

Figure 25 - Checking Gas Joints (Natural Gas Only)

![]()

![]()

![]()

![]()

![]() For

For![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() .

.![]()

![]()

![]()

![]() .com

.com![]()

![]()

![]()

![]()

![]()