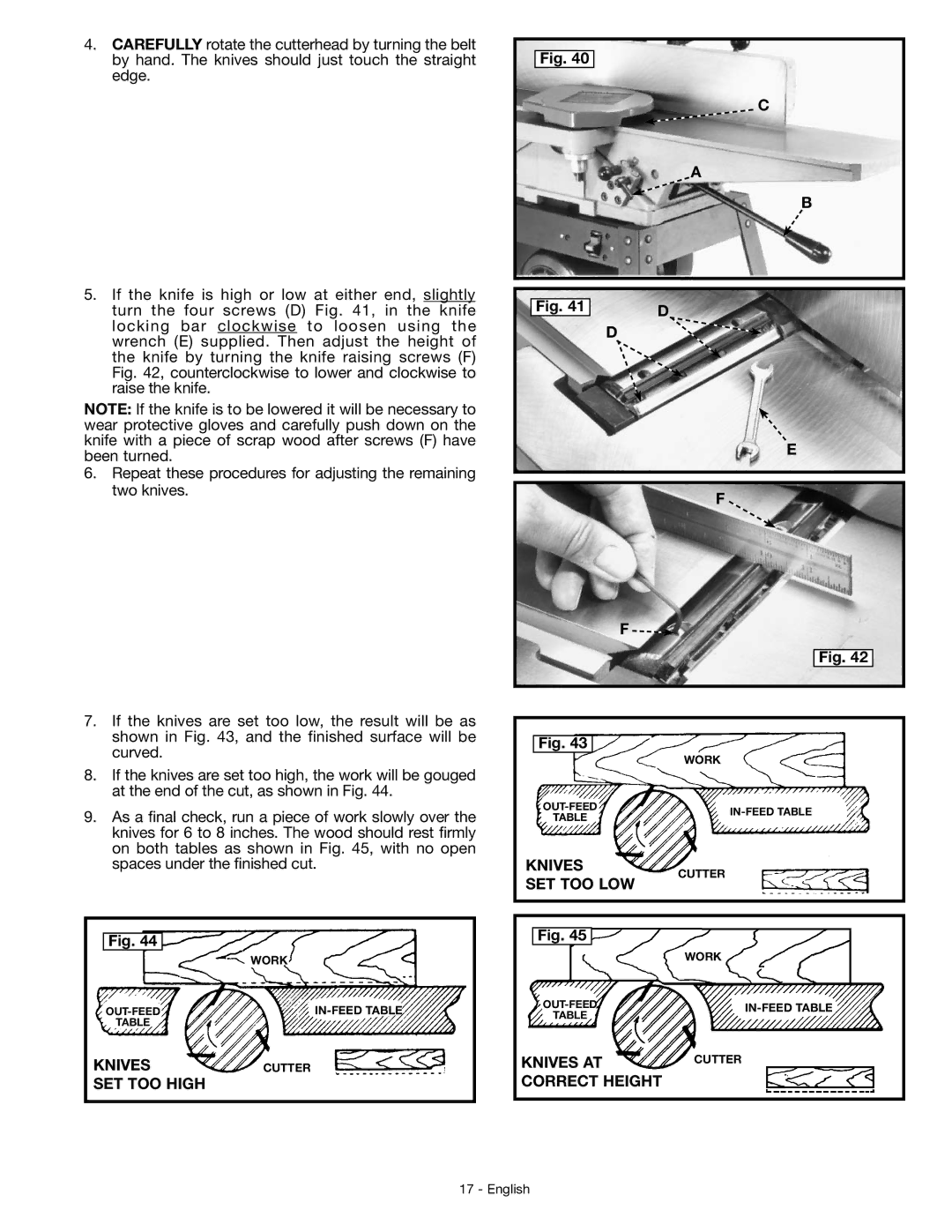

4.CAREFULLY rotate the cutterhead by turning the belt by hand. The knives should just touch the straight edge.

Fig. 40

C

A

B

5.If the knife is high or low at either end, slightly turn the four screws (D) Fig. 41, in the knife locking bar clockwise to loosen using the wrench (E) supplied. Then adjust the height of the knife by turning the knife raising screws (F) Fig. 42, counterclockwise to lower and clockwise to raise the knife.

NOTE: If the knife is to be lowered it will be necessary to wear protective gloves and carefully push down on the knife with a piece of scrap wood after screws (F) have been turned.

6.Repeat these procedures for adjusting the remaining two knives.

7.If the knives are set too low, the result will be as shown in Fig. 43, and the finished surface will be curved.

8.If the knives are set too high, the work will be gouged at the end of the cut, as shown in Fig. 44.

9.As a final check, run a piece of work slowly over the knives for 6 to 8 inches. The wood should rest firmly on both tables as shown in Fig. 45, with no open spaces under the finished cut.

Fig. 44

| WORK |

TABLE |

|

KNIVESCUTTER

SET TOO HIGH

Fig. 41 | D |

| |

| D |

E

F

F ![]()

Fig. 42

Fig. 43

WORK

TABLE | ||

|

KNIVES

CUTTER

SET TOO LOW

Fig. 45

| WORK |

TABLE |

|

KNIVES AT | CUTTER |

CORRECT HEIGHT |

|