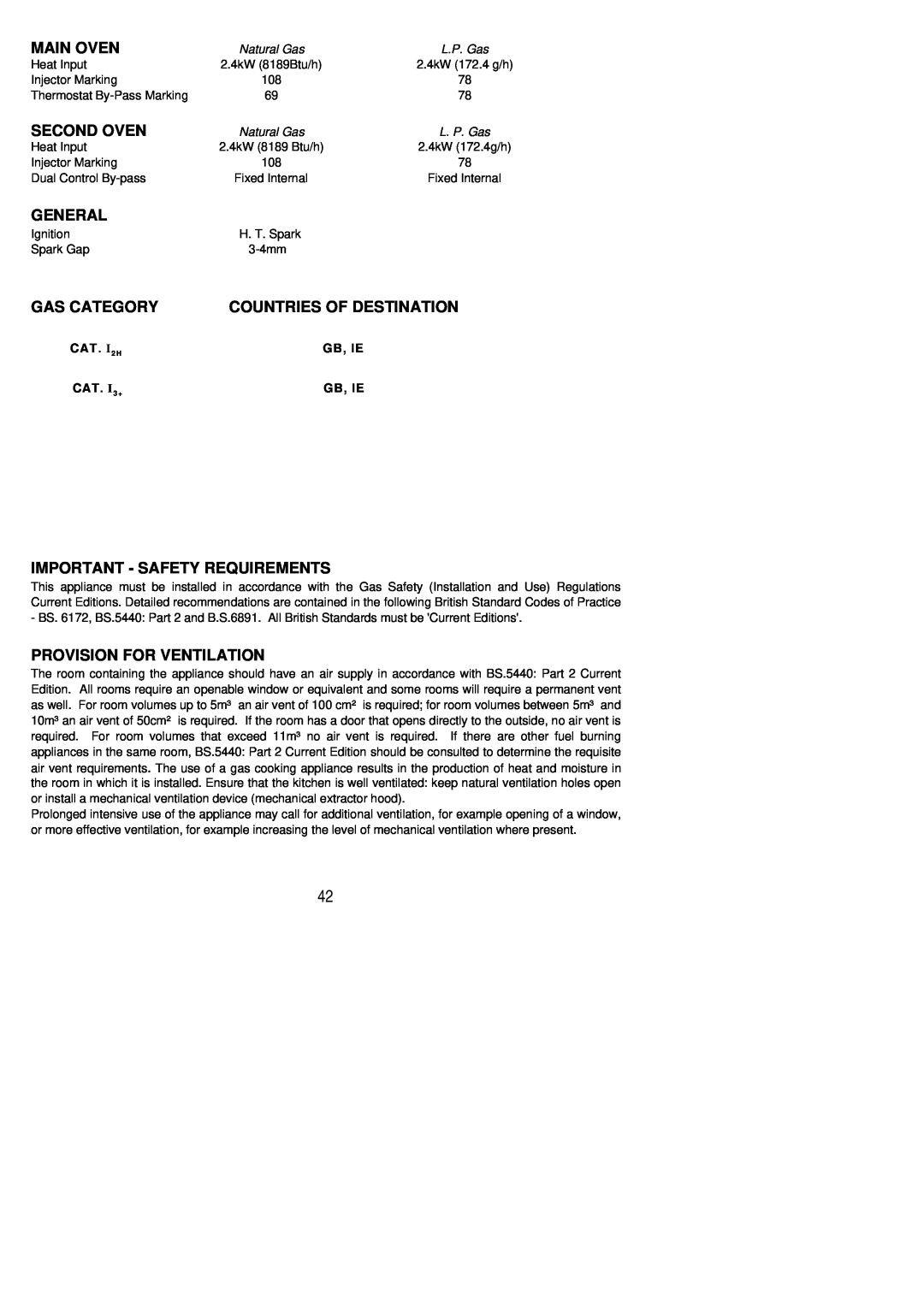

MAIN OVEN | Natural Gas | L.P. Gas |

Heat Input | 2.4kW (8189Btu/h) | 2.4kW (172.4 g/h) |

Injector Marking | 108 | 78 |

Thermostat | 69 | 78 |

SECOND OVEN | Natural Gas | L. P. Gas |

Heat Input | 2.4kW (8189 Btu/h) | 2.4kW (172.4g/h) |

Injector Marking | 108 | 78 |

Dual Control | Fixed Internal | Fixed Internal |

GENERAL |

|

|

Ignition | H. T. Spark |

|

Spark Gap |

| |

GAS CATEGORY | COUNTRIES OF DESTINATION | |

CAT. 12 H | GB, IE |

|

CAT. 13 + | GB, IE |

|

IMPORTANT - SAFETY REQUIREMENTS

This appliance must be installed in accordance with the Gas Safety (Installation and Use) Regulations Current Editions. Detailed recommendations are contained in the following British Standard Codes of Practice - BS. 6172, BS.5440: Part 2 and B.S.6891. All British Standards must be 'Current Editions'.

PROVISION FOR VENTILATION

The room containing the appliance should have an air supply in accordance with BS.5440: Part 2 Current Edition. All rooms require an openable window or equivalent and some rooms will require a permanent vent as well. For room volumes up to 5m³ an air vent of 100 cm² is required; for room volumes between 5m³ and 10m³ an air vent of 50cm² is required. If the room has a door that opens directly to the outside, no air vent is required. For room volumes that exceed 11m³ no air vent is required. If there are other fuel burning appliances in the same room, BS.5440: Part 2 Current Edition should be consulted to determine the requisite air vent requirements. The use of a gas cooking appliance results in the production of heat and moisture in the room in which it is installed. Ensure that the kitchen is well ventilated: keep natural ventilation holes open or install a mechanical ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example opening of a window, or more effective ventilation, for example increasing the level of mechanical ventilation where present.

42